Apparatus for cutting bead on inner surface of electric-resistance-welded steel pipe

A technology for electric welding steel pipes and cutting devices, which is applied in the direction of auxiliary devices, resistance welding equipment, high-frequency current welding equipment, etc., can solve problems such as increased cost, poor inner surface pressure, and delayed delivery, so as to prevent inner surface pressure , Prevent the effect of bad pressure on the inner surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention are shown below.

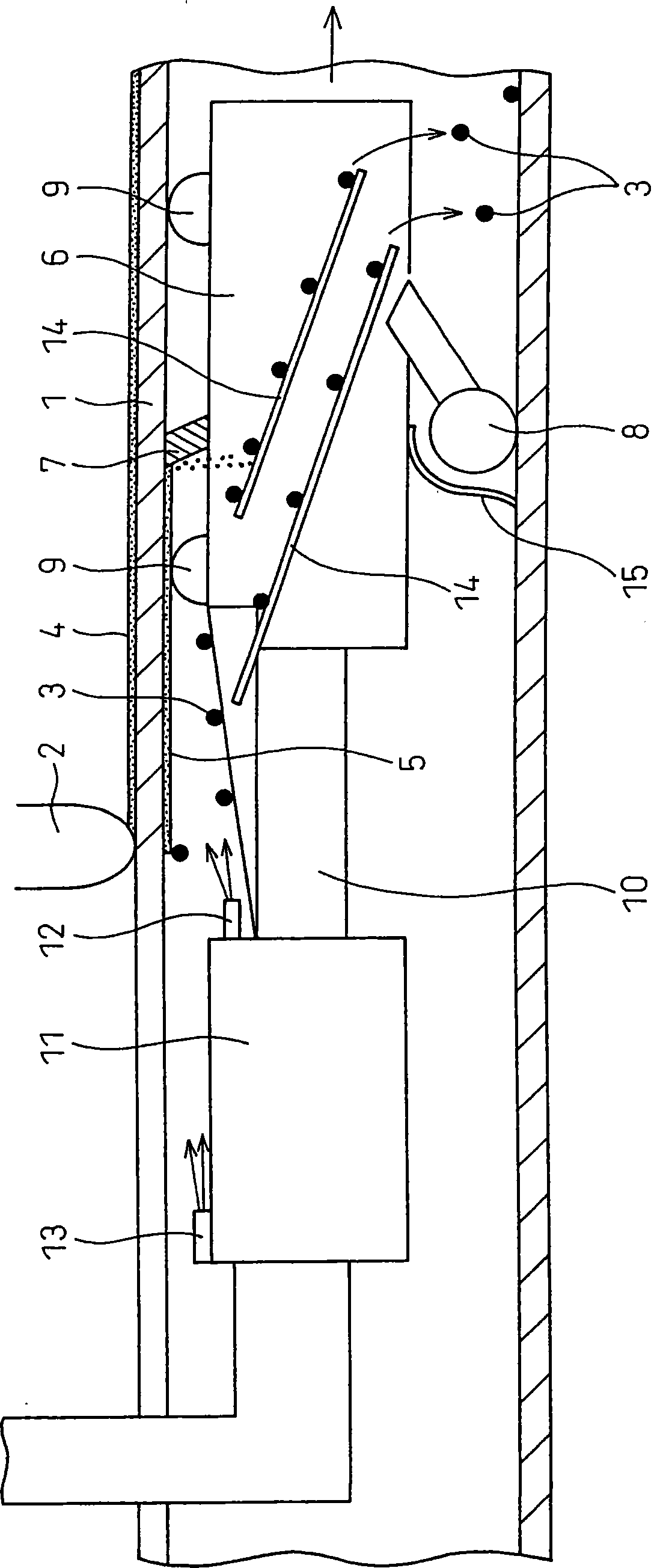

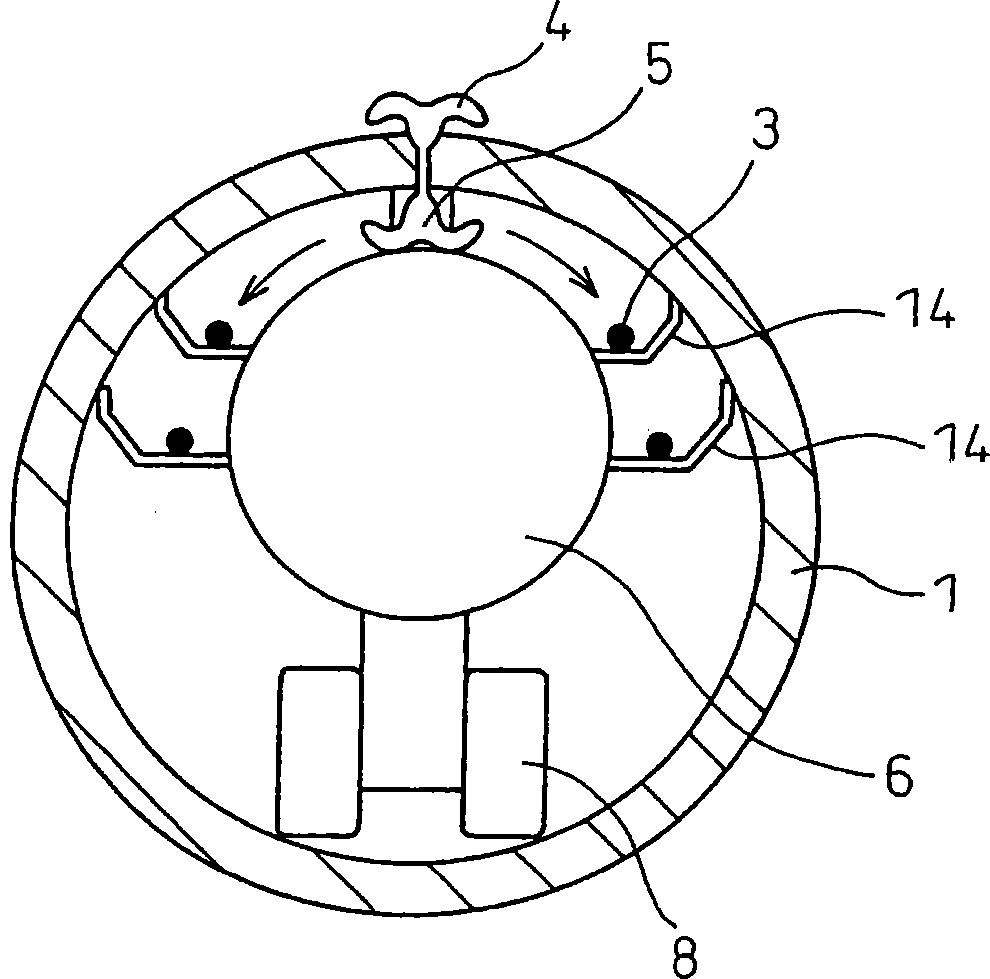

[0024] figure 1 is a cross-sectional view showing the longitudinal direction of a steel pipe according to an embodiment of the present invention, figure 2 With figure 1 Corresponding cross-sectional views in the vertical direction. 1 is a steel pipe. As is well known, a steel strip is slowly bent in the width direction by a plurality of forming rolls to form a tubular shape, and the end faces are continuously pressure-welded by pressure rollers while being pressed together to produce an electric welded steel pipe. exist figure 1 Among them, the lower end of the grout roller 2 is a welding point. Since steel pipe 1 is in figure 1 The right side runs continuously, and in this specification, the left side is referred to as the upstream side, and the right side is referred to as the downstream side.

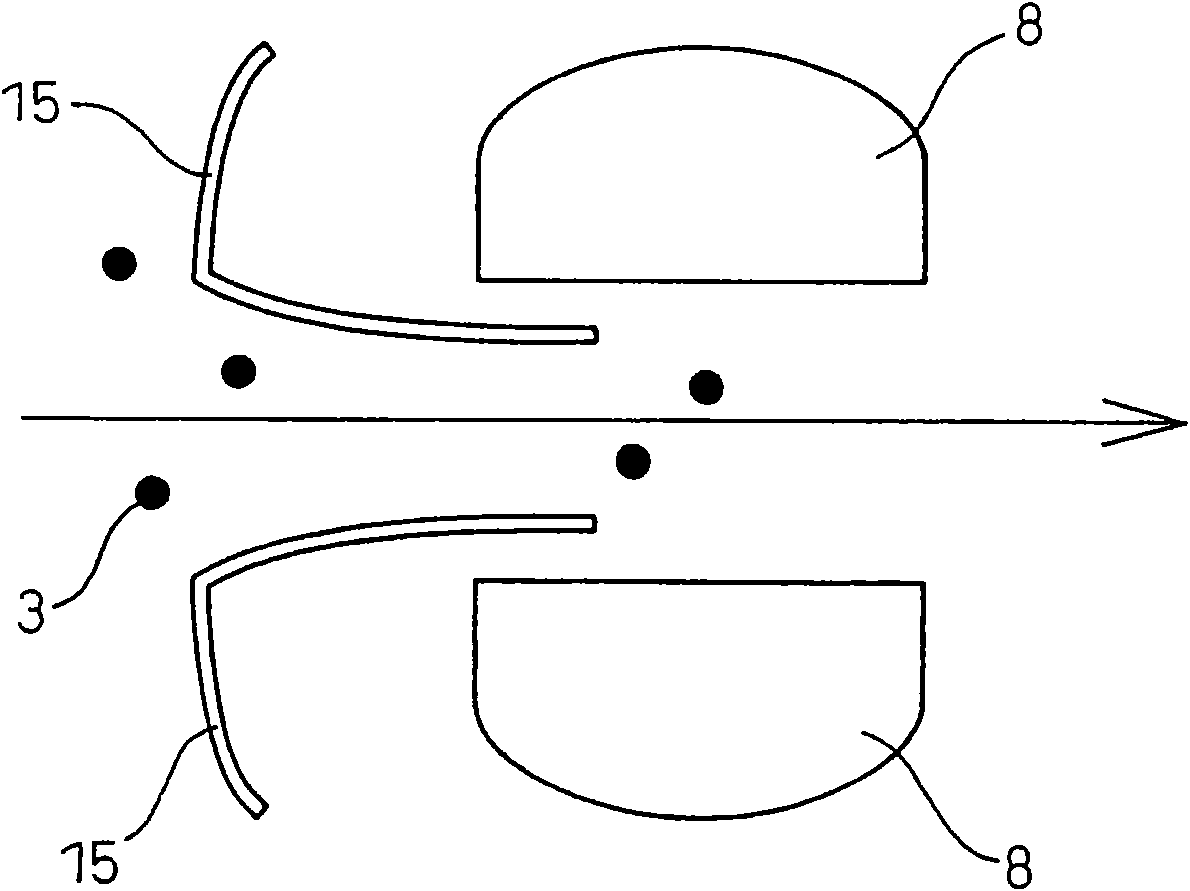

[0025] As described above, the outer surface bead 4 and the inner surface bead 5 are formed along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com