Improved utilization of linear alpha olefins in production of metallocene catalyzed poly-alpha olefins

A technology of metallocene catalyst and alpha olefin, applied in the field of poly alpha olefin production, can solve problems such as shortage of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

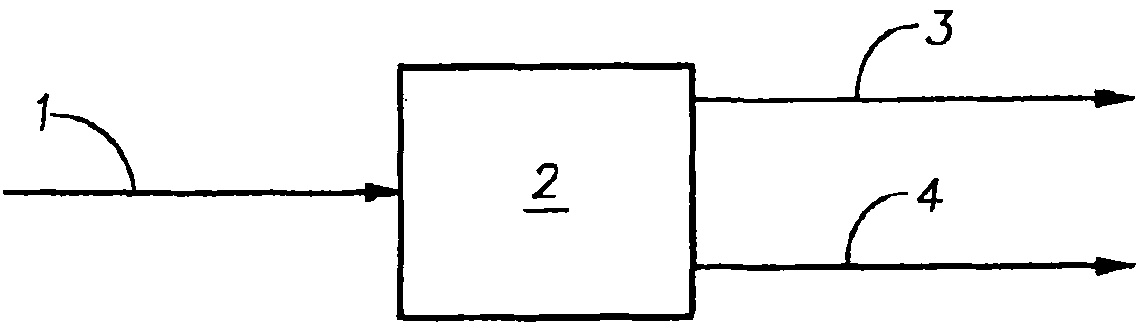

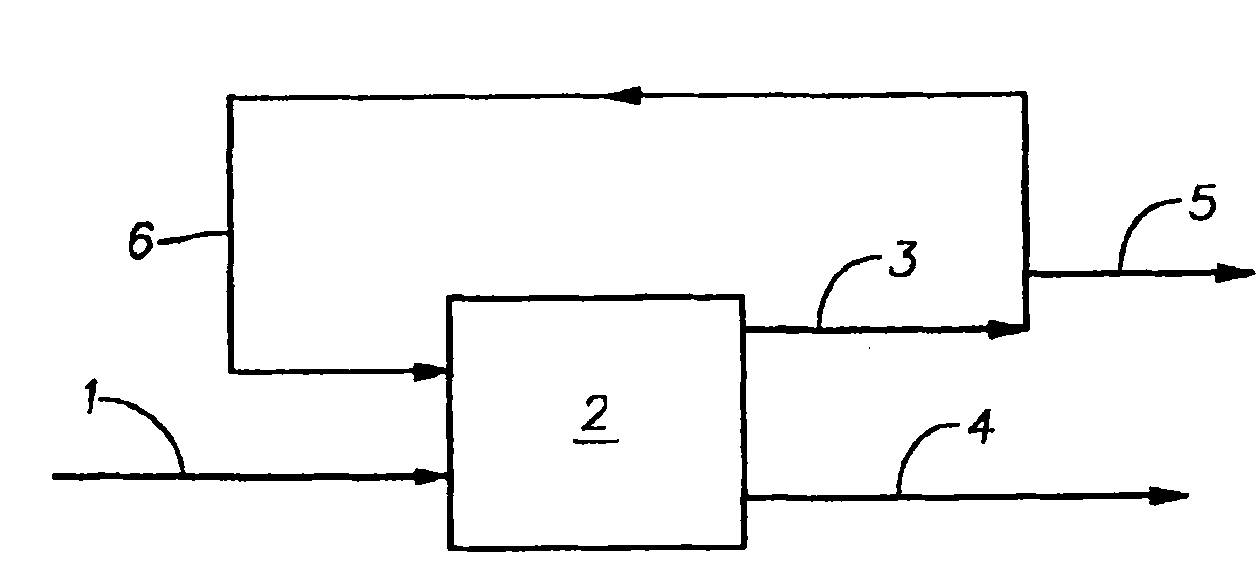

Method used

Image

Examples

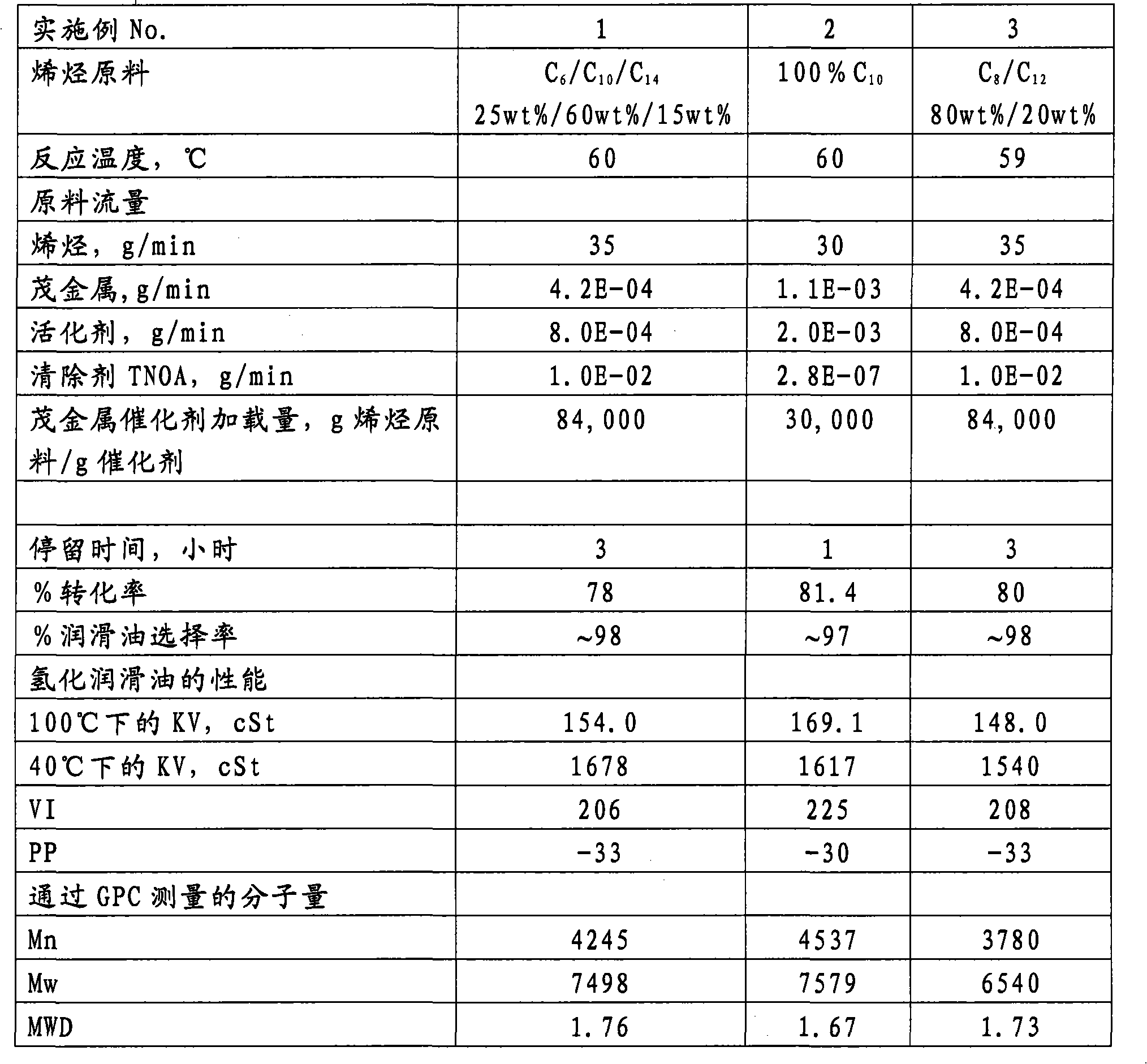

Embodiment 1-3

[0073] This set of experiments was performed in a continuous reactor model. These runs produced PAO products with narrow molecular weight distributions and demonstrated that using non-coordinating anions (NCAs) as activators resulted in high lube oil yields. The olefins used in these runs were purified by passing through 3-5 Angstrom molecular sieves.

[0074] The metallocene catalyst used was dimethylsilylbis[tetrahydroindenyl]zirconium dimethyl and the activator used was N,N-dimethylanilinium tetrakis(pentafluorophenyl)borate .

[0075] The catalyst solution was prepared by premixing the metallocene catalyst with the activator in a toluene solution to obtain 0.0025 g catalyst per 1 g solution. Perform experiments within a single CSTR system. The autoclave reactors used in these experiments ranged in size from 1 liter to 2 gallons. All raw materials are continuously introduced into the CSTR at a fixed flow rate. CSTR is controlled at a given reaction temperature. Cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com