Cast tube water cooling system used for centrifugal casting machine

A technology of centrifugal casting and water cooling system, applied in the field of casting pipe water cooling system, can solve the problems of inability to cool in sections, poor cooling effect, low production efficiency, etc., so as to avoid excessive local temperature changes, reduce scrap rate, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0012] At present, the water cooling pipeline inside the centrifuge body in the cast-pipe water cooling system is not segmented, but a through-pipe. A sprinkler head is connected to the water cooling pipeline, and only one water inlet and one outlet are set in the waterway. The nozzle can not be cooled in stages according to the needs of production, so there are many disadvantages. Therefore, the present invention improves its structure.

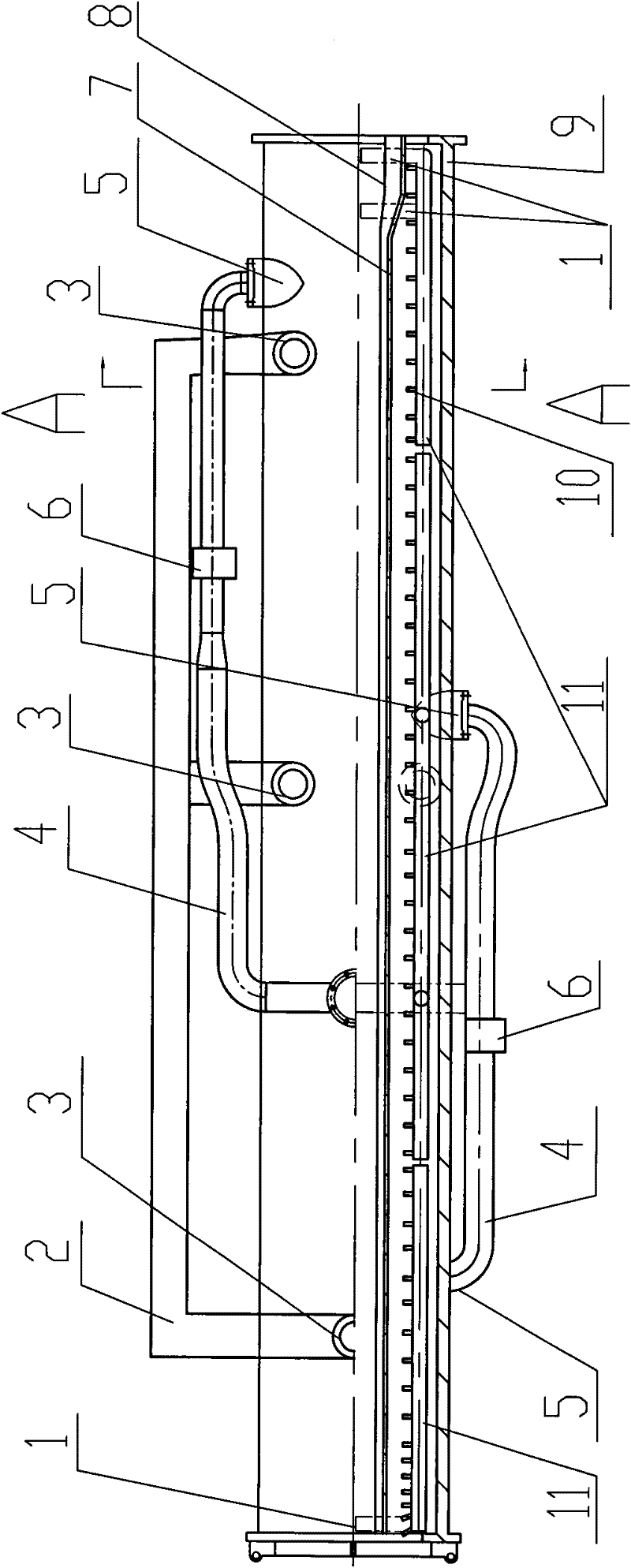

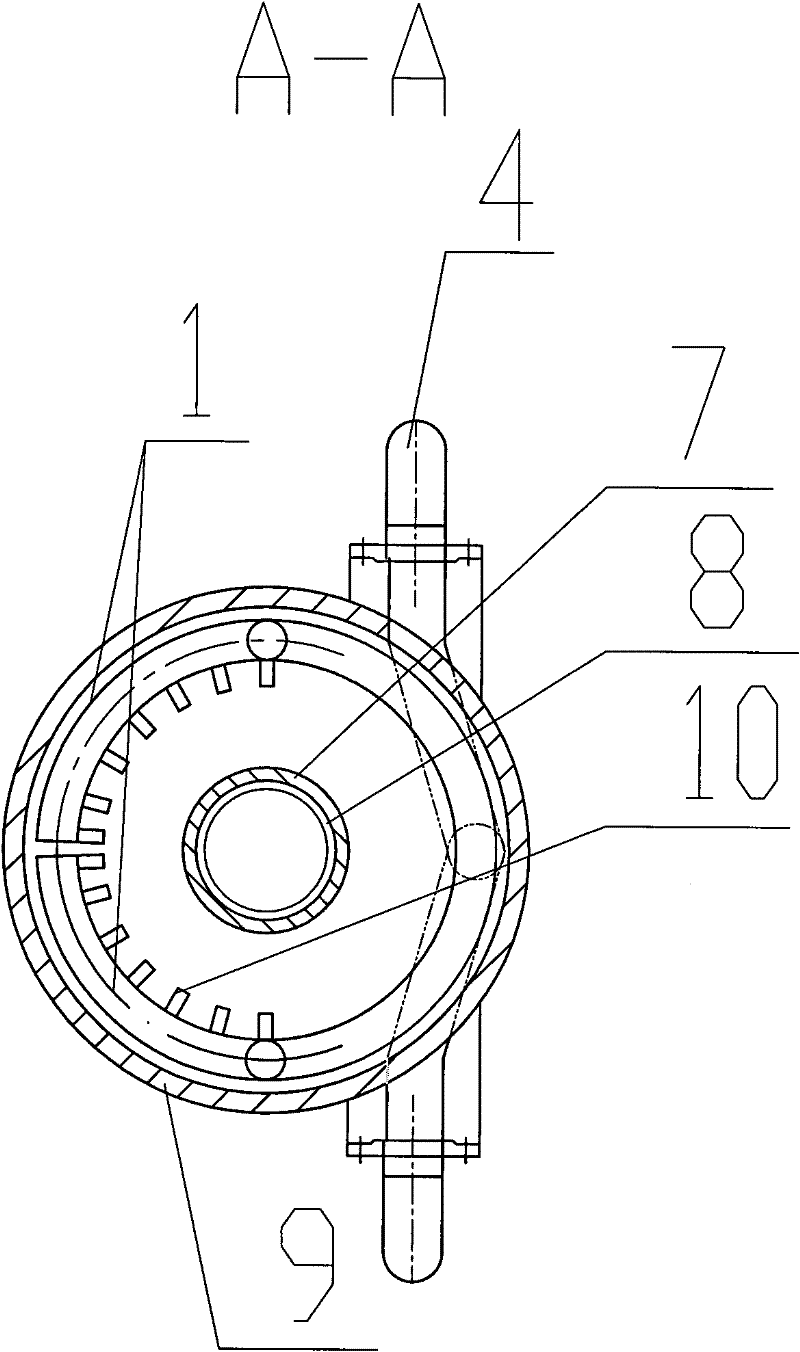

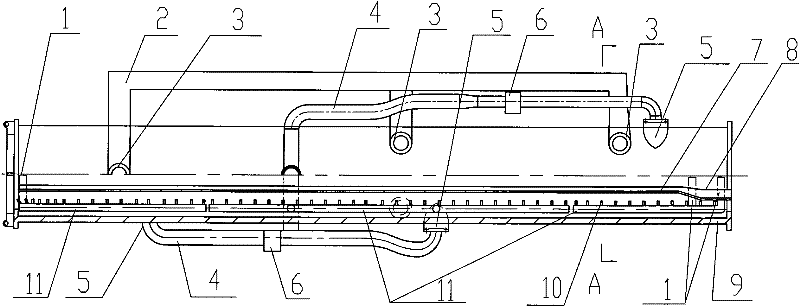

[0013] see attached figure 1 , its structure includes a water inlet pipeline 4 arranged outside the centrifuge body 9 and an outlet water cooling pipeline 11 arranged inside the centrifuge body 9. 11 is divided into three sections, and each section of water cooling pipeline 11 is provided with an independent water inlet 5 and three matching water outlets 3. The water outlet 3 is arranged in the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com