Method for controlling electric heating smoking set to heat cigarette

A technology of electric heating and cigarette sticks, which is applied in the direction of tobacco, etc., can solve the problems of reducing battery efficiency, energy waste, and long heating element time, and achieve the effect of increasing the heating rate, increasing accuracy, and shortening the warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

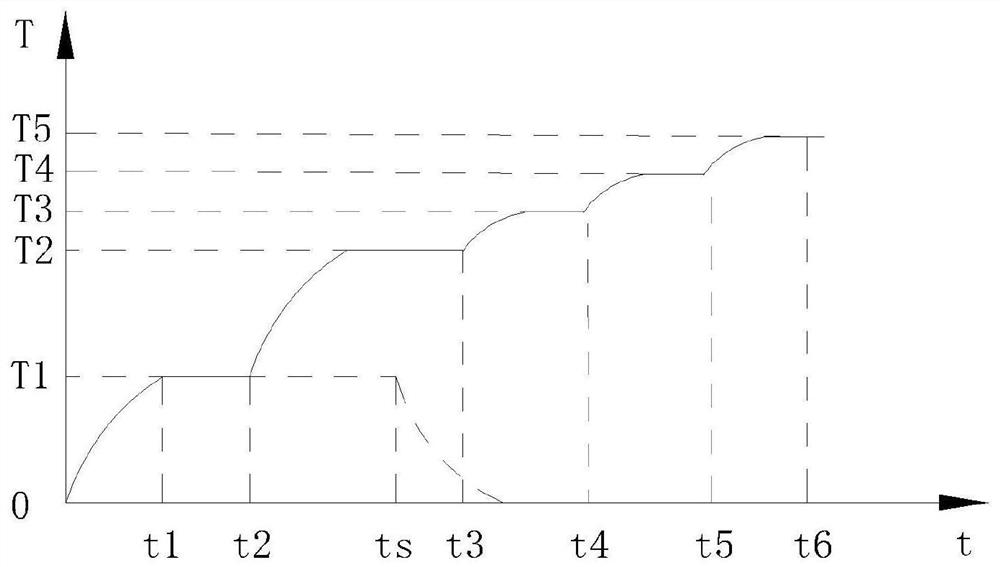

[0031] The following times t1, t2, ts, t3, t4, t5 and t6 are all counted from when the smoking appliance is activated.

[0032] The duration of setting the first temperature T1 of the smoking appliance is 30s.

[0033] When using a heat-not-burn smoking appliance, start the smoking appliance first, and the smoking appliance controller controls the power output to the heating element, so that the temperature of the heating element rises to the first temperature T1, such as 150 degrees Celsius, and takes time t1, such as 10s, until the temperature of the heating element reaches the first temperature T1 After a temperature T1, reduce the power output to the heating element to make it consistent with the heat dissipation power of the heating element at this temperature, so that the temperature of the heating element remains at the first temperature T1 for a period of time.

[0034] At time t2, such as 17s, the prepared cigarette is inserted into the smoking set. Since the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com