Telescopic single-container hanger

A container spreader, telescopic technology, applied in hoisting devices, transportation and packaging, load hanging components, etc., can solve the problems of poor environmental protection, many faults, and heavy weight of the spreader, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

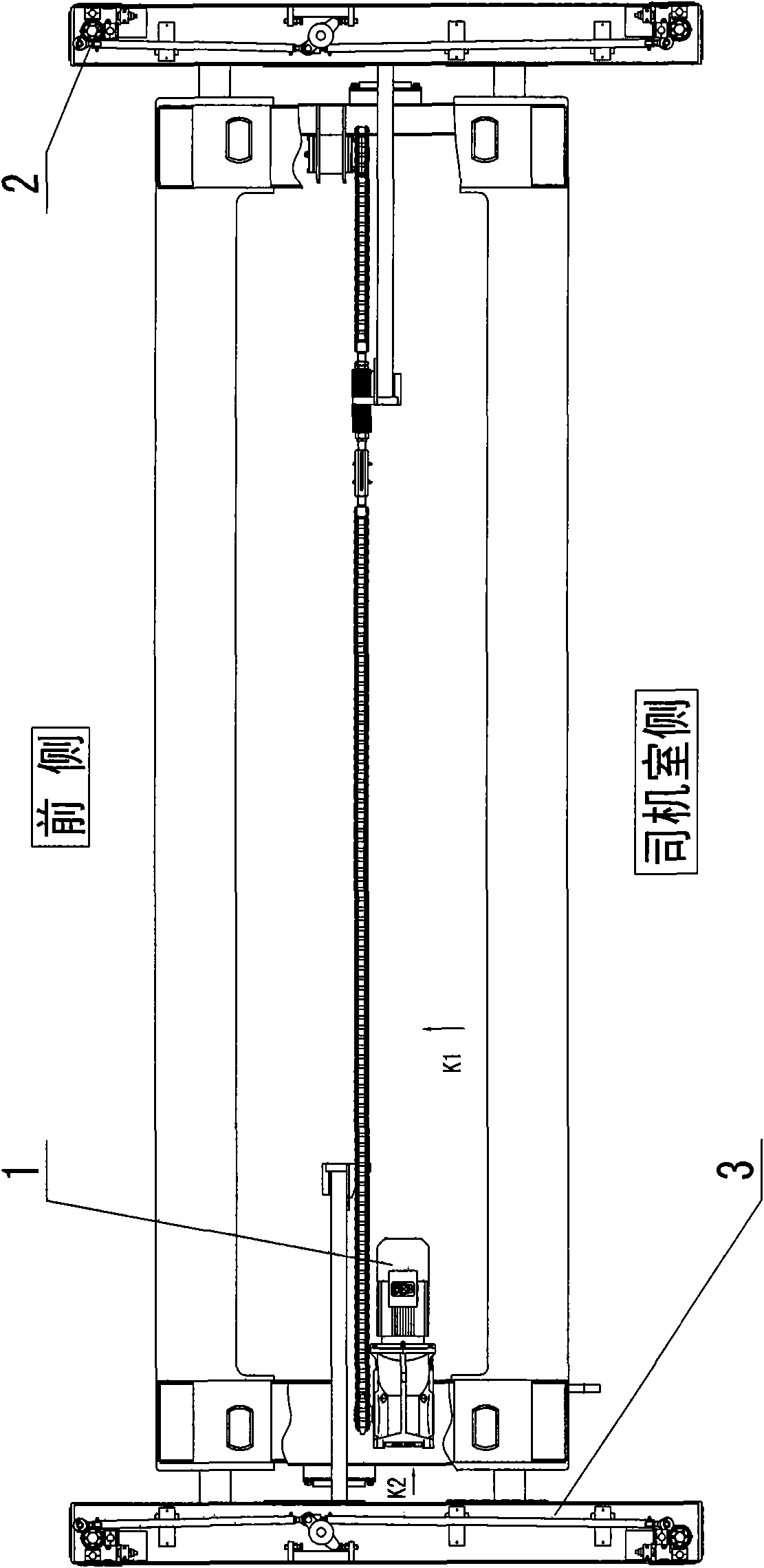

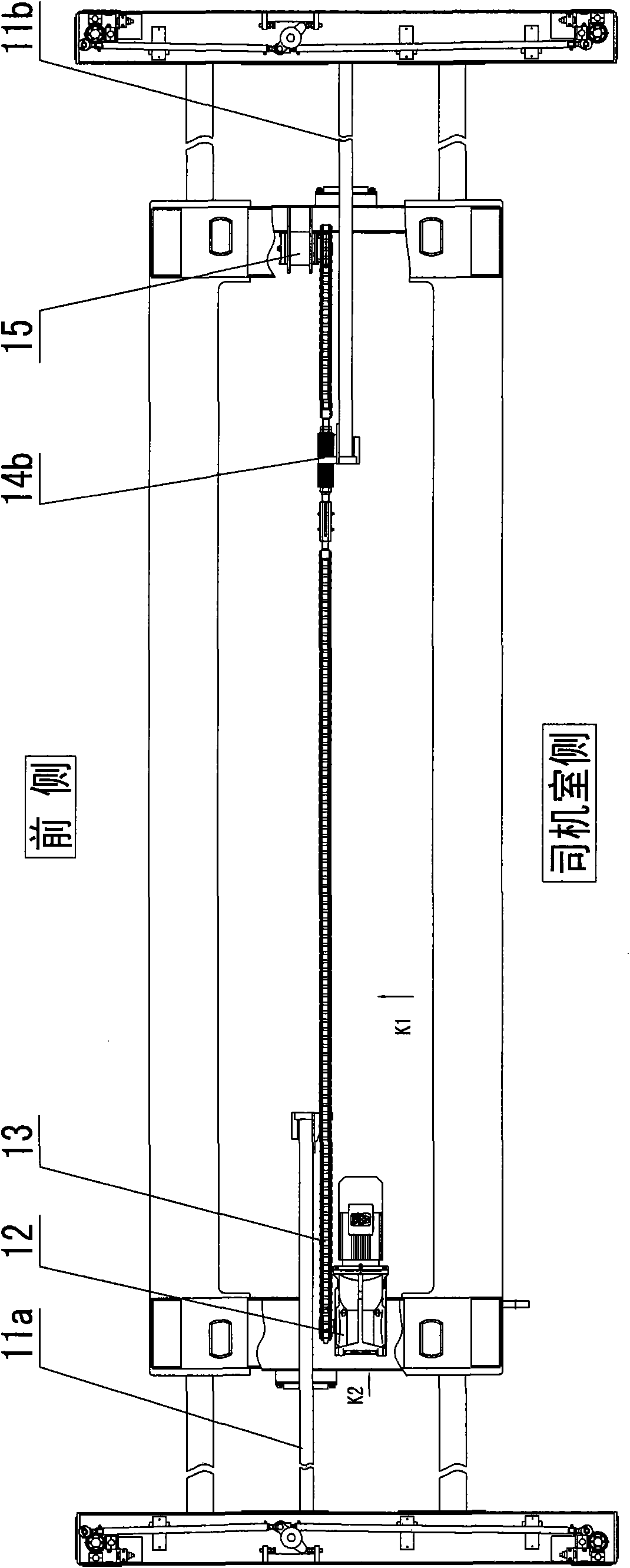

[0024] Figure 1A It is a front view of a single container spreader according to an embodiment of the present invention. Figure 1B It is a top view of a single container spreader according to an embodiment of the present invention. Such as Figure 1A , 1B As shown, the single-container spreader of this embodiment is mainly embodied in a servo motor type telescopic movement mechanism 1 and a servo motor type repin mechanism 2, wherein the action of the telescopic movement mechanism 1 drives the movement of the two end beams 3, as shown in 1B and figure 2 shown.

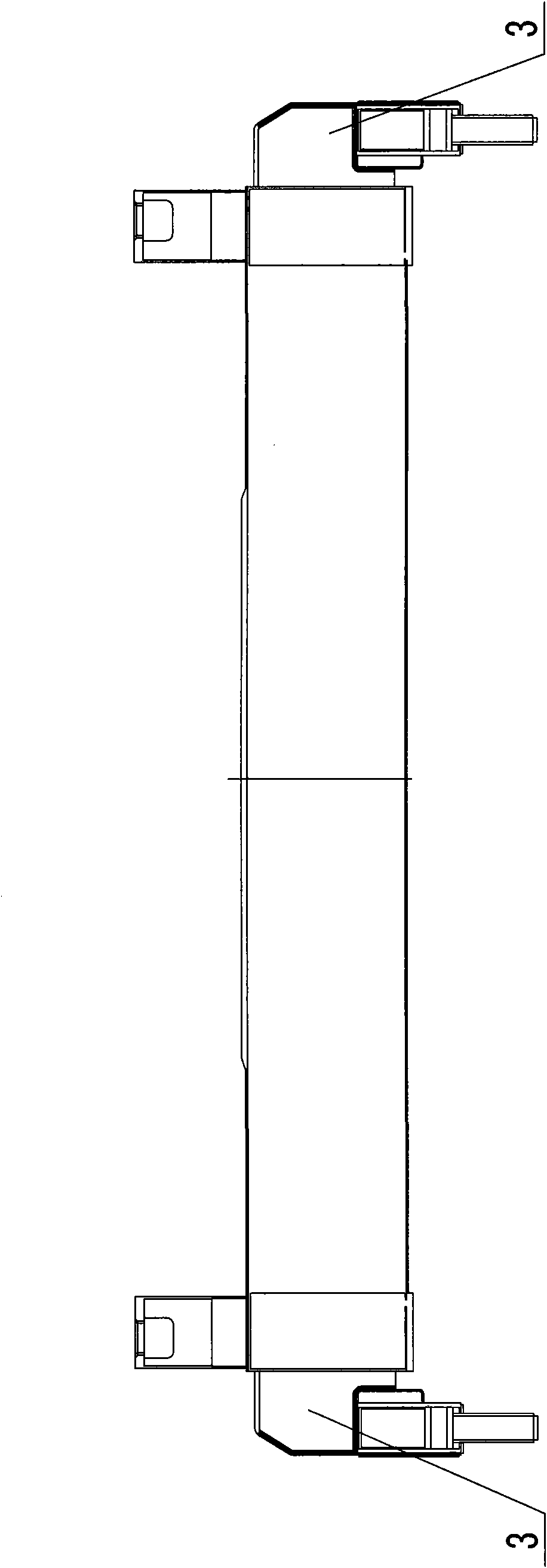

[0025] figure 2 It is a top view of a single container spreader according to an embodiment of the present invention. image 3 for figure 2 View from K1 direction in . Figure 4 for figure 2 The view from the direction of K2 in which the solid line part is composed of parts of the telescopic movement mechanism. Such as figure 2 , image 3 , Figure 4 As shown, the telescopic moving mechanism 1 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com