Anti-sway jacklift

A technology for lifting trolleys and trolleys, which is applied in the directions of load hanging components, transportation and packaging, etc., can solve the problems of difficult processing, increased power consumption, increased power of lifting and running motors, etc., to reduce additional The effect of weight, reduction in processing, and saving of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

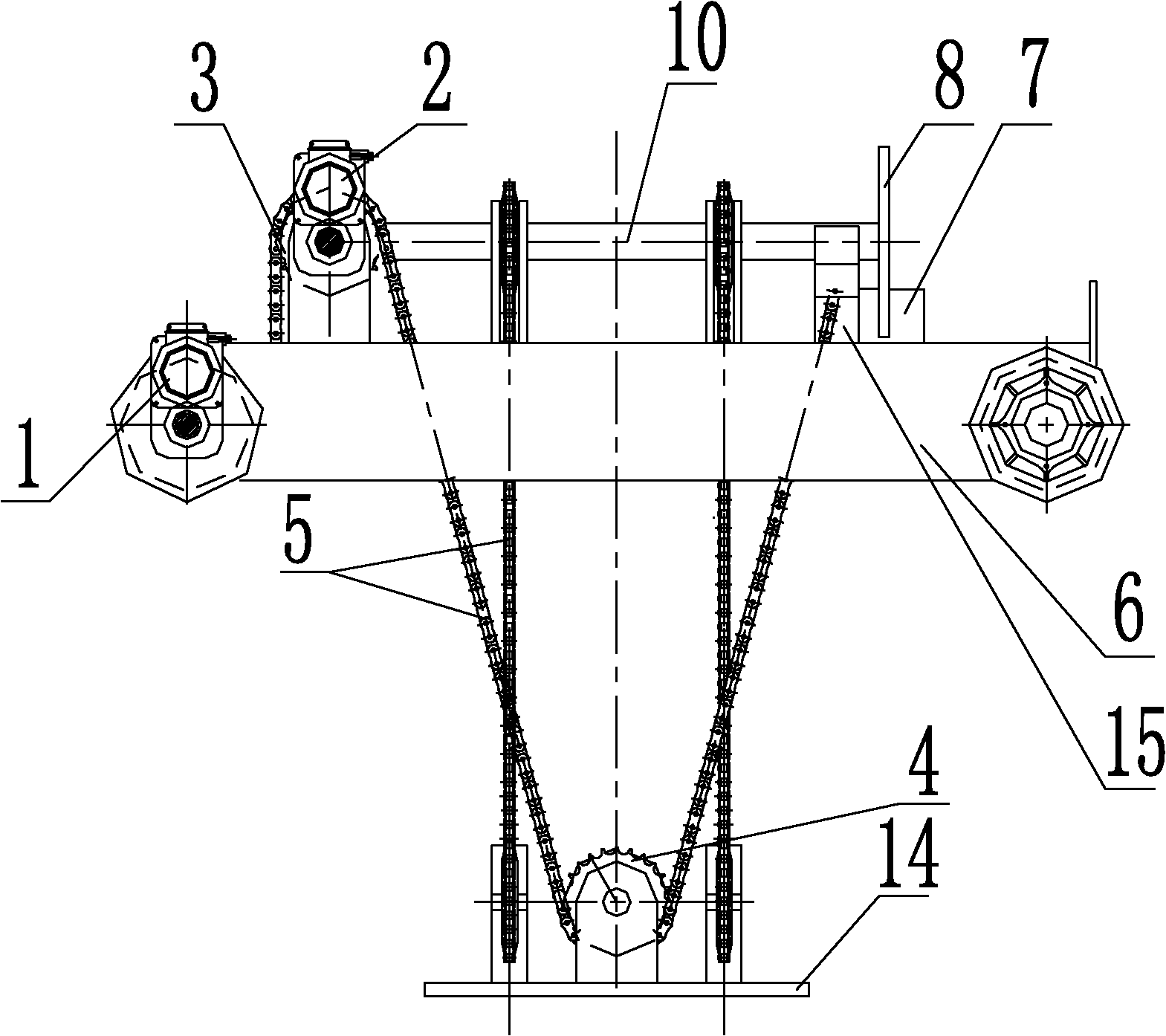

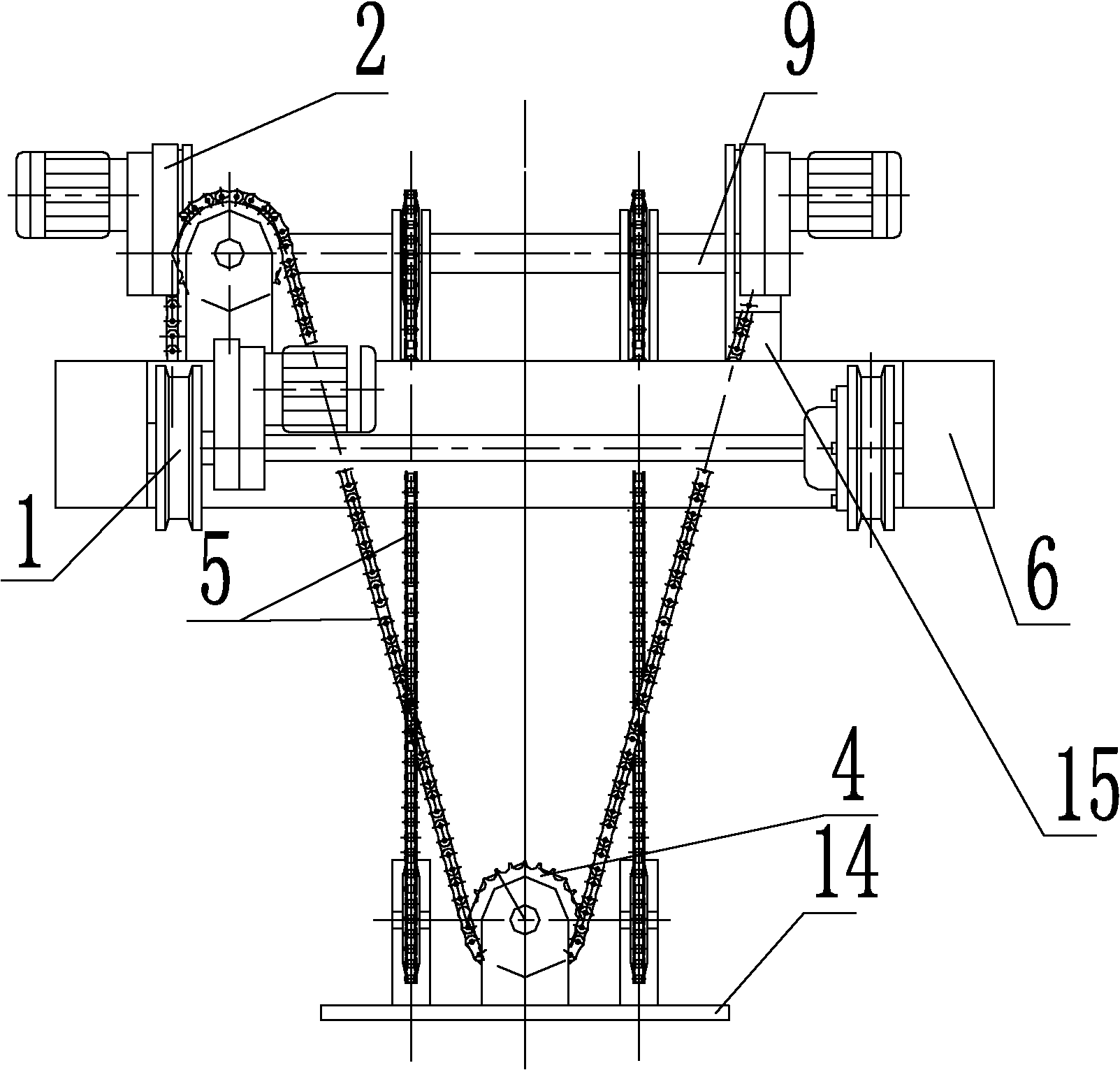

[0020] see figure 1 with figure 2 , an anti-shake lifting trolley, comprising a trolley frame 6, a trolley drive device 1 mounted on the trolley frame and a lifting drive device 2, the power shaft 9 of the lifting drive device is connected to the transmission shaft 10 and is vertical, and the power The shaft will be connected with the transmission shaft through bevel gears. The power shaft and the transmission shaft are equipped with at least two lifting sprockets 3, and the trolley frame is also provided with a chain support 15. Each chain 5 has one end connected to the chain support. Link to each other, the other end links to each other with hoisting sprocket 3, is provided with at least four hanging plate sprockets 4 on the hanging plate 14, the bottom of hanging plate is connected with spreader, and hanging plate sprocket links to each other with chain.

[0021] Wherein, two chains worn on the lifting sprocket 3 of the drive shaft pass through the hanging plate sprockets...

Embodiment 2

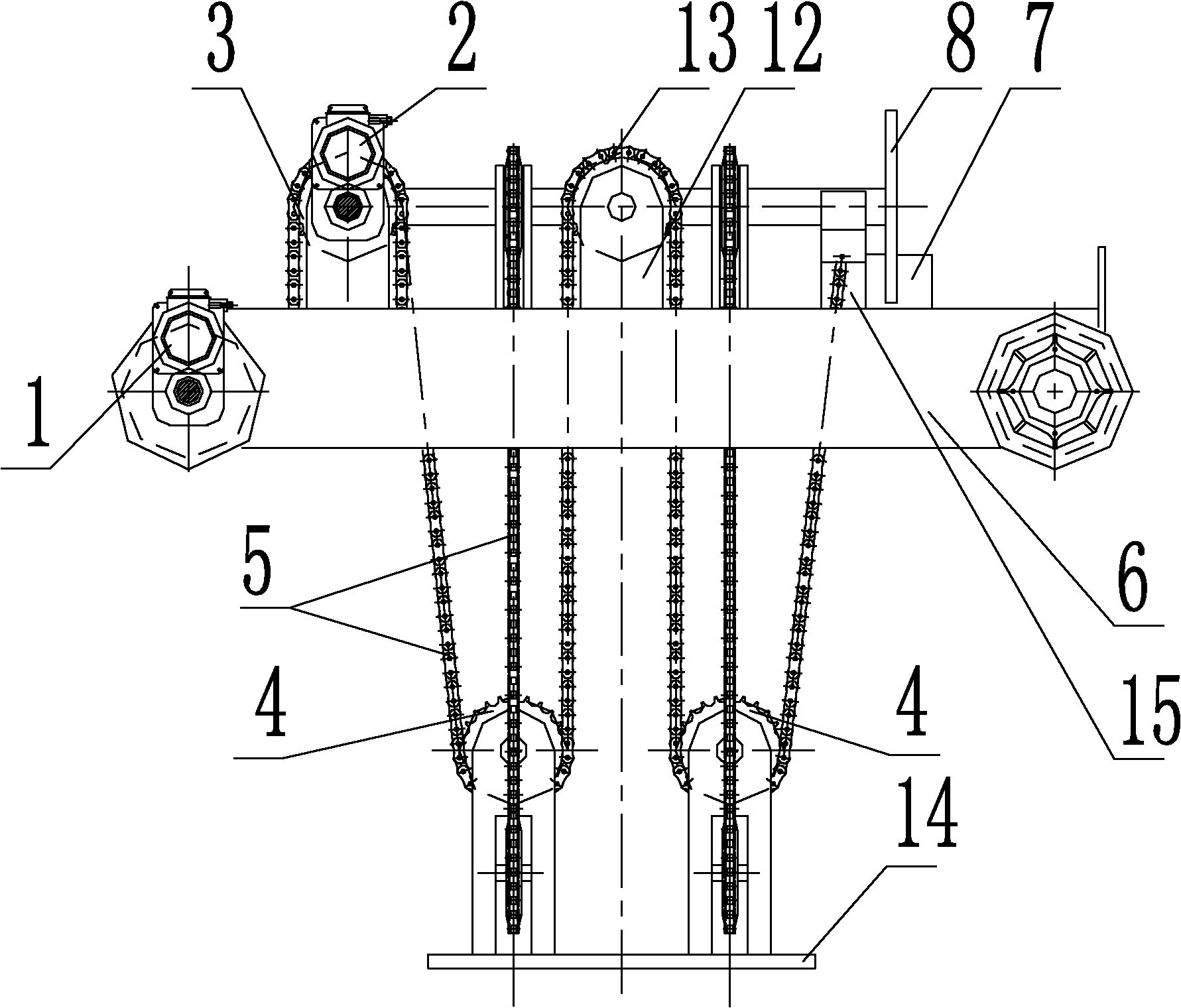

[0024] see Figure 3-Figure 5 , an anti-shake lifting trolley, comprising a trolley frame 6, a trolley drive device 1 mounted on the trolley frame and a lifting drive device 2, the power shaft 9 of the lifting drive device is connected to the transmission shaft 10 and is vertical, and the power The shaft will be connected with the transmission shaft through bevel gears. The power shaft and the transmission shaft are equipped with at least two lifting sprockets 3, and the trolley frame is also provided with a chain support 15. Each chain 5 has one end connected to the chain support. Link to each other, the other end links to each other with hoisting sprocket 3, is provided with at least four hanging plate sprockets 4 on the hanging plate 14, the bottom of hanging plate is connected with spreader, and hanging plate sprocket links to each other with chain.

[0025] The trolley frame is also provided with four transition sprocket brackets 12, each transition sprocket bracket is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com