Converter transformer for inhibiting DC magnetic biasing

A converter transformer and DC bias technology, which is applied in the field of transformer manufacturing, can solve problems such as transformer no-load loss increase, power grid collapse, and vibration aggravation, and achieve the goal of reducing the degree of DC bias, reducing the impact and harm, and reducing vibration aggravation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

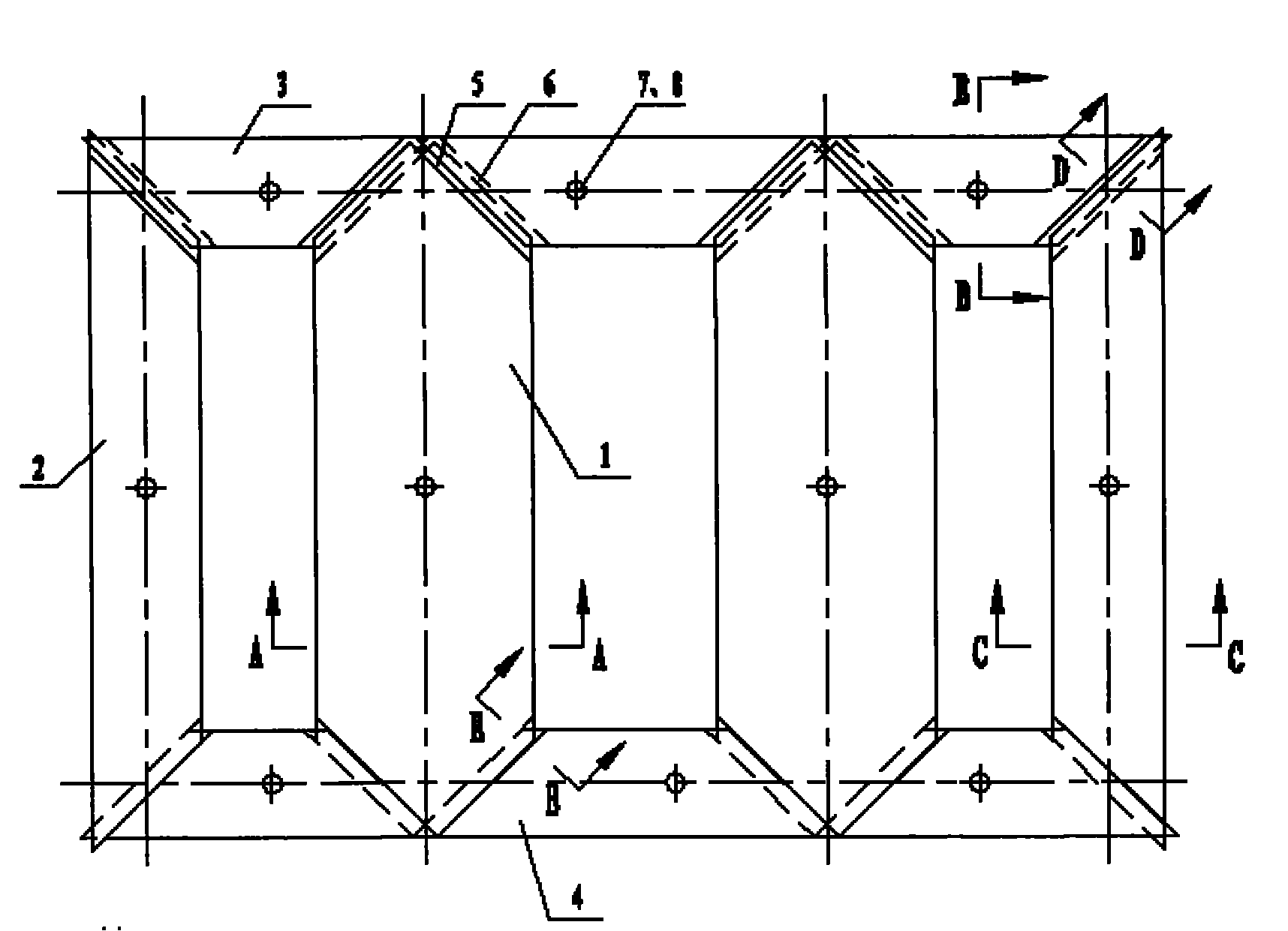

[0028] The method of the present invention is applied to a core-type transformer with side columns in the iron core, and is mainly reflected in increasing the joint width of the transformer iron core laminations, specifically:

[0029] Calculate the width and height of each level of lamination according to the reserved lamination joint width, core section, column spacing and window height;

[0030] Cut the laminations according to the lamination width and height calculated above;

[0031] Laminations are stacked two by one in the order of each level, and placed alternately on the core frame by level;

[0032] After all the laminations are stacked, fasten the laminations at all levels.

[0033] The seam width is not less than the tolerance, and is not greater than the seam center distance between adjacent two-stage laminations.

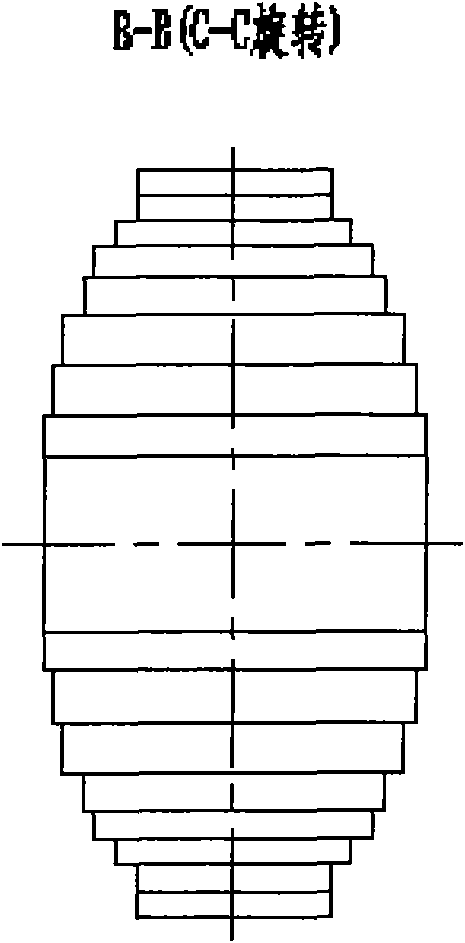

[0034] Such as Figure 2A-2E As shown, the iron core in this embodiment is a single-phase four-leg, including two main legs 1 , two side legs 2 , t...

Embodiment 2

[0041] Such as Figure 3A-3E As shown, the difference from Example 1 is that the iron core is a single-phase three-column, including one main column 1, two side columns 2, two upper yokes 3, two lower yokes 4, and the number of joints is 6 , all by increasing the width. The core laminations are still stacked in two, the first-level joints 5 and the second-level joints 6 are alternately placed, and the fastening of the laminations at all levels is still in the form of a combination of positioning holes 7 and through-core screws 8 .

[0042] According to the different technological requirements of various converter transformers, the laminations at all levels can be alternately placed with 1-6 joints respectively, and the laminations at all levels can also be fastened by adhesive bonding or strapping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com