Speed control system and shunting system for shunting equipment

A speed control and shunting technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high operator requirements, manpower consumption, hidden dangers, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

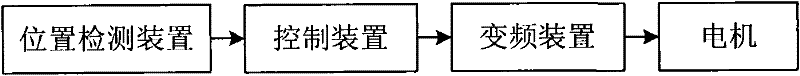

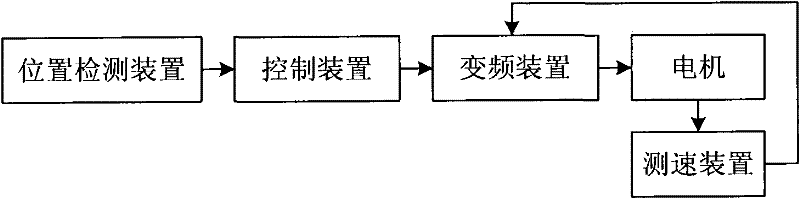

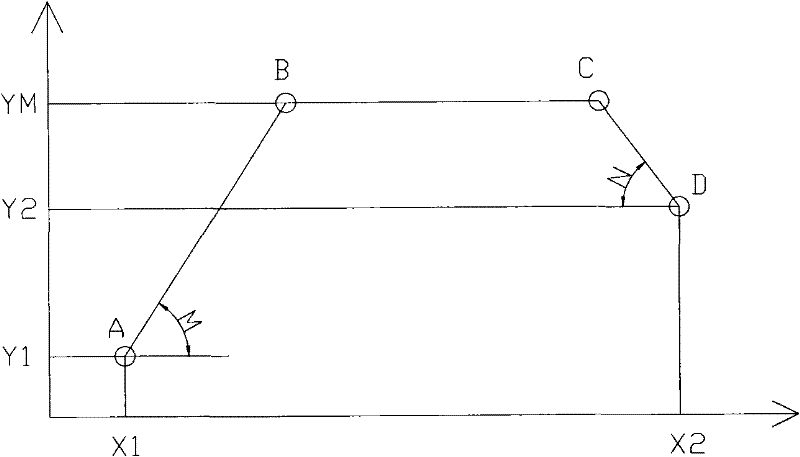

[0011] Such as figure 1 As shown, the present invention provides a speed control system for shunting equipment. The speed control system includes a position detection device, a control device and a frequency conversion device connected to each other; the position detection device is used to detect where the shunting equipment is located. and transmit the detected current position to the control device; the control device is used for receiving the current position of the shunting equipment from the position detection device, and for The corresponding curve outputs a speed control signal corresponding to the current position to the frequency conversion device, wherein the position-speed corresponding curve is obtained by fitting according to the initial speed, initial position and preset step parameters of the shunting equipment , the preset step parameters include target position, target speed, maximum speed, acceleration and deceleration; and the frequency conversion device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com