Aluminum-magnesium-silicon series aluminum alloy material with middle and high intensity

An aluminum-magnesium-silicon technology, which is applied in the field of aluminum-magnesium-silicon series aluminum alloy materials, can solve the problems of difficult forming, difficult processing, and poor ductility of 7 series alloys, and achieves less investment in casting equipment, less damage, and casting performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

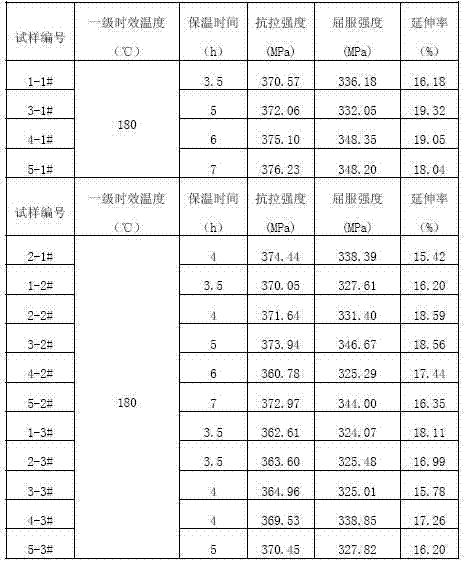

Examples

Embodiment 1

[0020] Example 1, the present invention provides a medium-high-strength aluminum-magnesium-silicon-based aluminum alloy material, the components of which contain the following elements in mass percent: silicon 0.72; iron 0.3; copper 0.35; magnesium 1.05; manganese 0.13; zinc 0.047; titanium 0.034; chromium 0.099; the rest is aluminum.

Embodiment 2

[0021] Example 2, the present invention provides a medium-high-strength aluminum-magnesium-silicon-based aluminum alloy material, the components of which contain the following elements in mass percent: silicon 0.71; iron 0.31; copper 0.32; magnesium 1.02; manganese 0.13; zinc 0.028; titanium 0.035; chromium 0.12; the rest is aluminum.

Embodiment 3

[0022] Example 3, the present invention provides a medium-high-strength aluminum-magnesium-silicon-based aluminum alloy material, the components of which contain the following elements in mass percent: silicon 0.50; iron 0.32; copper 0.33; magnesium 1.35; manganese 0.12; zinc 0.035; titanium 0.040; chromium 0.11; the rest is aluminum.

[0023] The melting and casting process of the medium-high strength aluminum-magnesium-silicon-based aluminum alloy material comprises the following steps:

[0024] ⑴According to the above-mentioned component ratio, the ingredients except magnesium element are smelted in the furnace, and the temperature is 730-760 0 C, the time is 3h ~ 3.5h;

[0025] (2) According to the proportion of components, add magnesium element into the melting furnace, stir, and continue smelting for 0.5h, while removing slag;

[0026] ⑶ refining, the temperature is 720 ~ 750 0 C, the time is 15min, and the slag is removed at the same time;

[0027] ⑷Casting: use tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com