Construction method for assembling integral hollow slab bridge

A technology of hollow slab bridge and construction method, which is applied in the direction of erecting/assembling bridges, bridge construction, building structures, etc., can solve problems such as limited transmission of shear force, stress on single slabs, hidden dangers of bridge traffic safety, etc., and achieve simplification Prefabrication and construction technology, improved dynamic performance, and significant benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

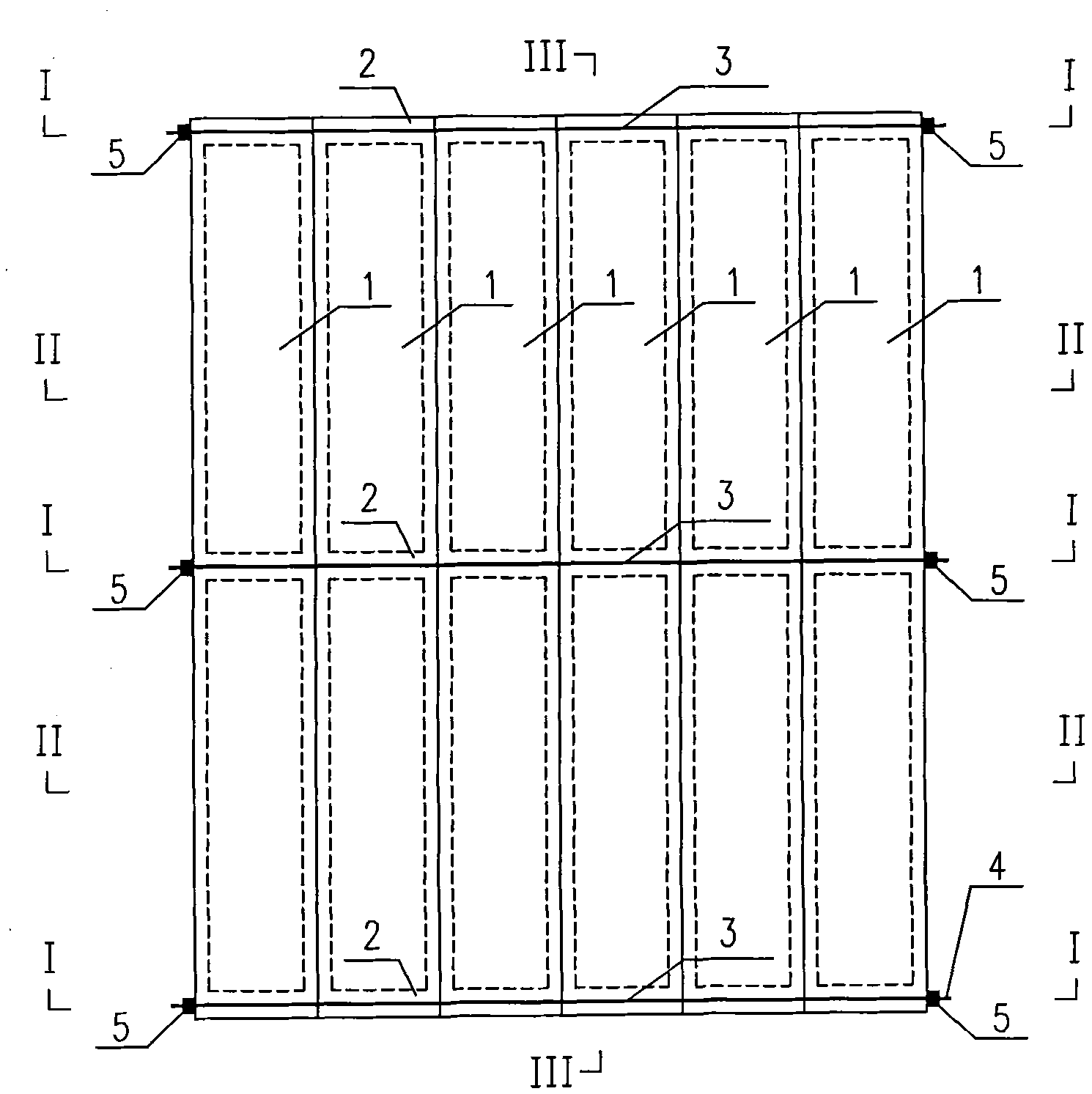

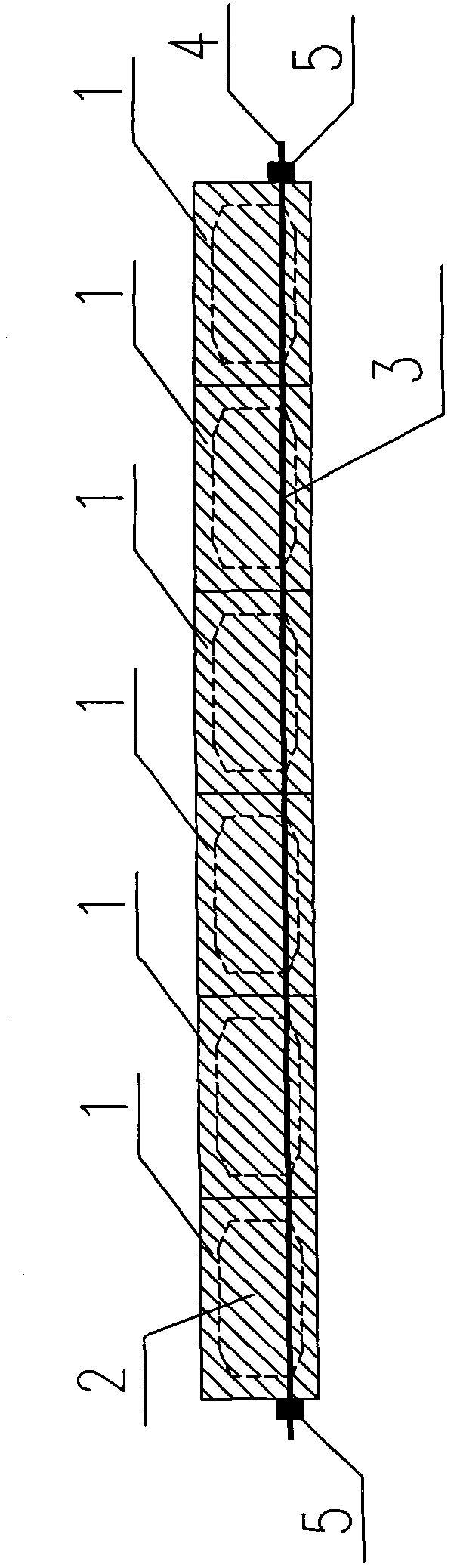

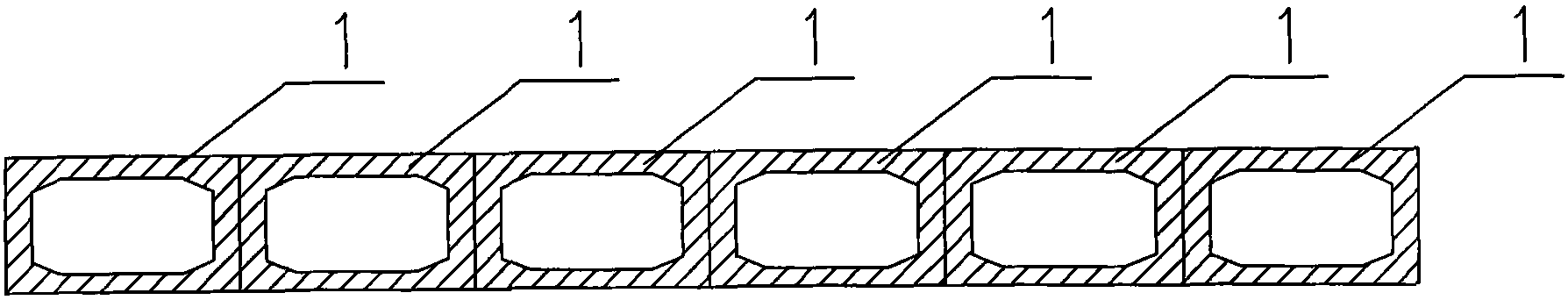

[0023] Example: such as Figure 1-4 As shown, a construction method for assembling a monolithic hollow slab bridge comprises the following steps:

[0024] (1) Prefabricated prestressed hollow slab: prefabricated hollow slab in the prefabrication factory according to the design requirements. The sides of the hollow plate are processed into straight edges. Set three transverse partitions at the two ends and the mid-span of the hollow slab (the polystyrene foam inner film can be used to replace the traditional inner film to set the transverse diaphragm), and the transverse partition is arranged inside the transverse partition The design position of the stressed steel bar or the prestressed cable with sheath forms a transverse prestressed channel through the method of pre-embedded pipeline, and the pre-embedded pipeline can use metal bellows, iron pipe or plastic bellows. Concrete is poured, and longitudinal prestressed reinforcement is applied by pretensioning process.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com