Wind power utilization method and special device in wind discharge barrel of mine

A special device and exhaust duct technology, which is applied in the ventilation of mines/tunnels, wind engines consistent with the wind direction, wind power generation, etc., can solve the problems of affecting the air volume and service life of underground mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

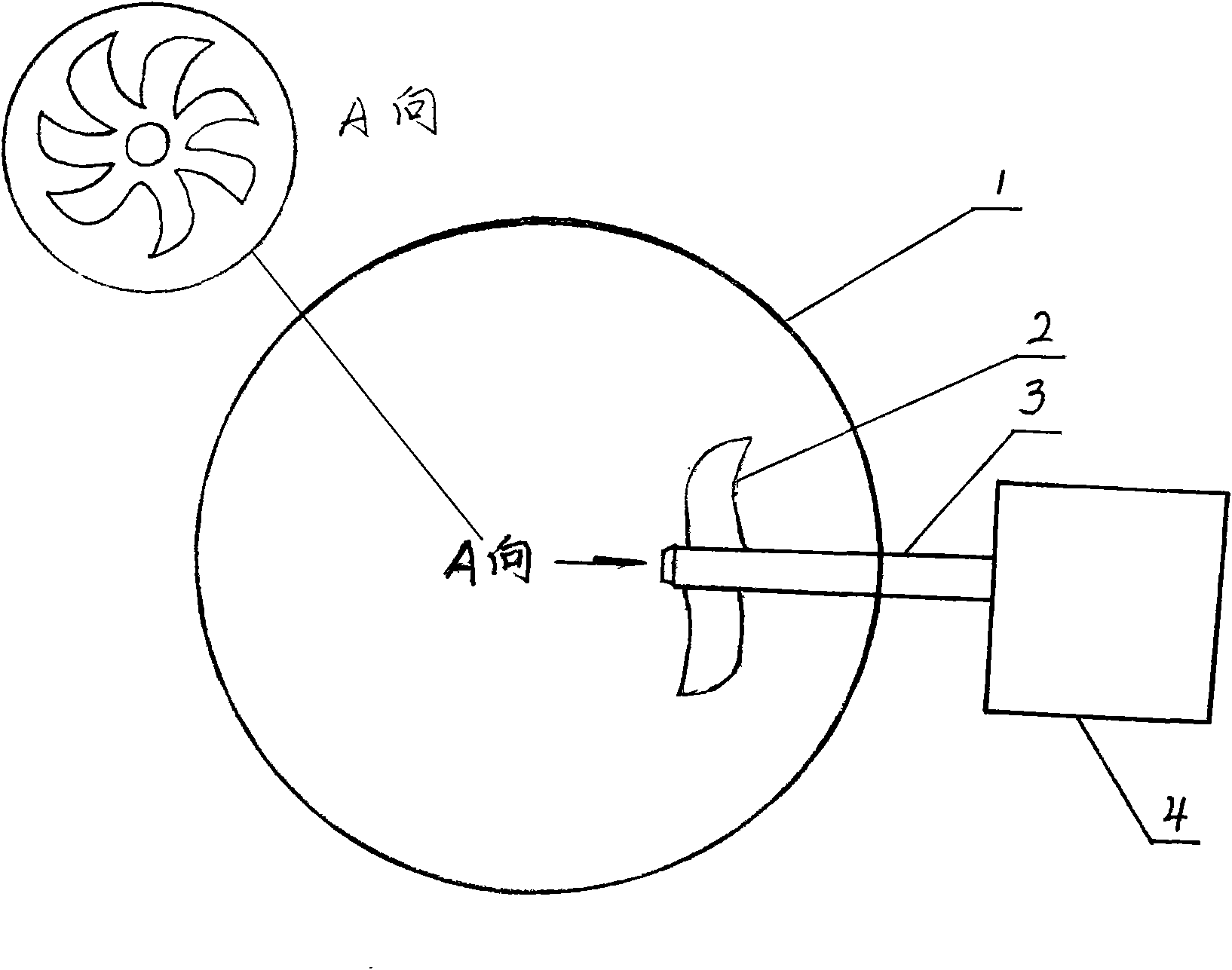

[0025] Wind energy utilization method and special device in a kind of mine exhaust duct of embodiment 1 of the present invention (see figure 1 ), it takes the wind energy utilization of a small-scale gold mine exhaust duct as the design object, the wind speed in the duct is not high, and the underground ventilation performance is better. The object of the circular exhaust cylinder 1 is 3 meters high. In order not to affect the discharge of the air volume in the exhaust cylinder 1, when designing the outlet section of the exhaust cylinder 1 is 1 meter away from the outlet end, and a wall is made on the cylinder wall. The impeller shaft hole, the generator 4 is arranged on the outside of the exhaust cylinder 1, and is installed on the generator frame. The impeller 2 of the generator is located inside the exhaust cylinder 1. The impeller 2 has seven impeller blades evenly distributed around the impeller shaft. The impeller 2 is connected with the generator 4 on the outside of the...

Embodiment 2

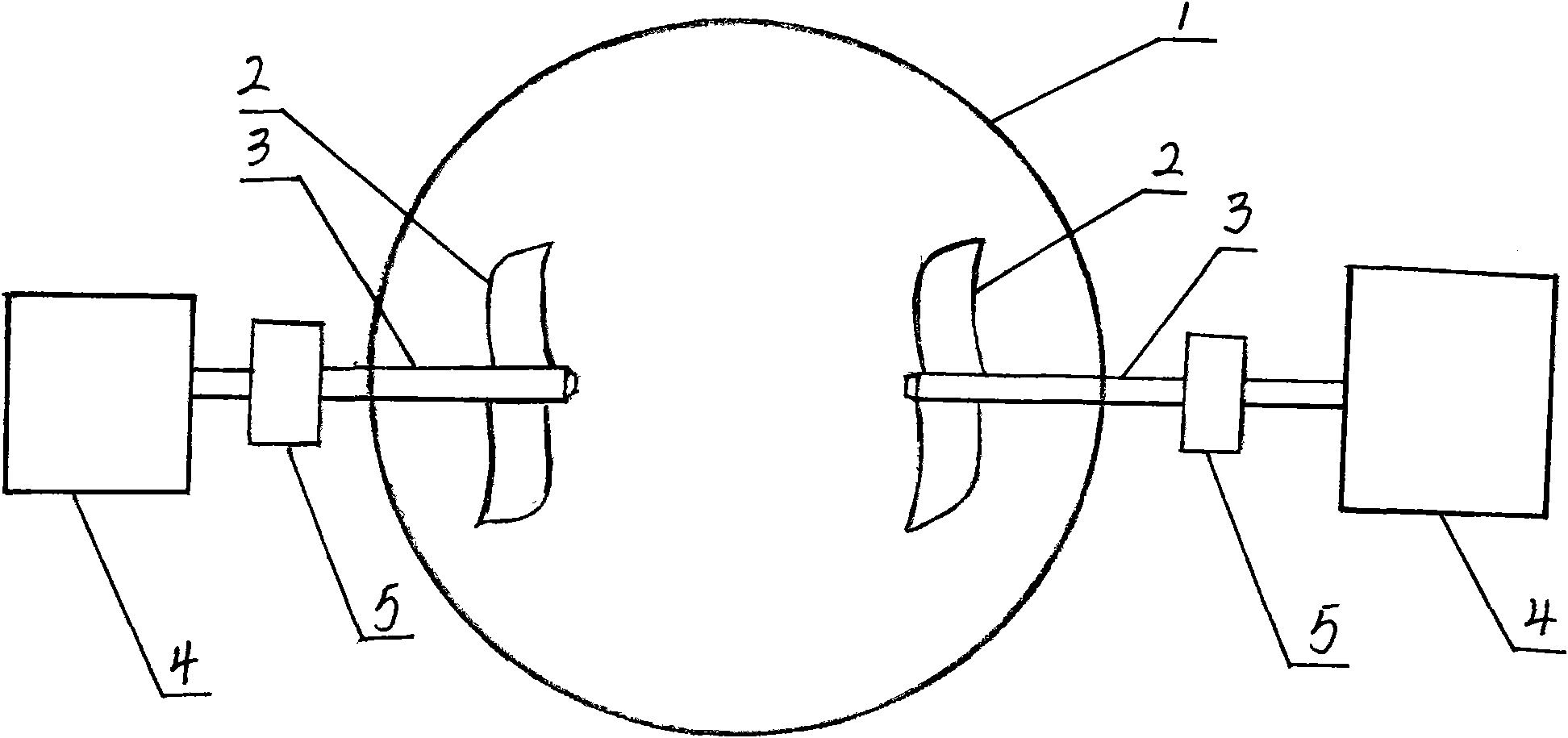

[0027] Wind energy utilization method and special device in a kind of mine exhaust duct of embodiment 2 of the present invention (see figure 2 ), it takes the wind energy utilization of the mine exhaust duct of a medium-sized gold mine as the design object, the wind speed requirement is higher, and the underground ventilation performance is better. The exhaust cylinder 1 is the object of implementation, and the exhaust cylinder 1 is 3 meters high. A pair of impeller shaft holes are arranged symmetrically on the exhaust cylinder body 1, and the impeller shaft 3 passes through the impeller shaft holes, and the impeller 2 is installed on the top end of the impeller shaft 3 in the inner cavity of the exhaust cylinder body 1, and the impeller 2 has four impellers The blades are evenly distributed around the impeller shaft, and after the other end of the impeller shaft 3 is installed with a reduction device 5, it is connected with the generator 4, and the generator 4 is installed o...

Embodiment 3

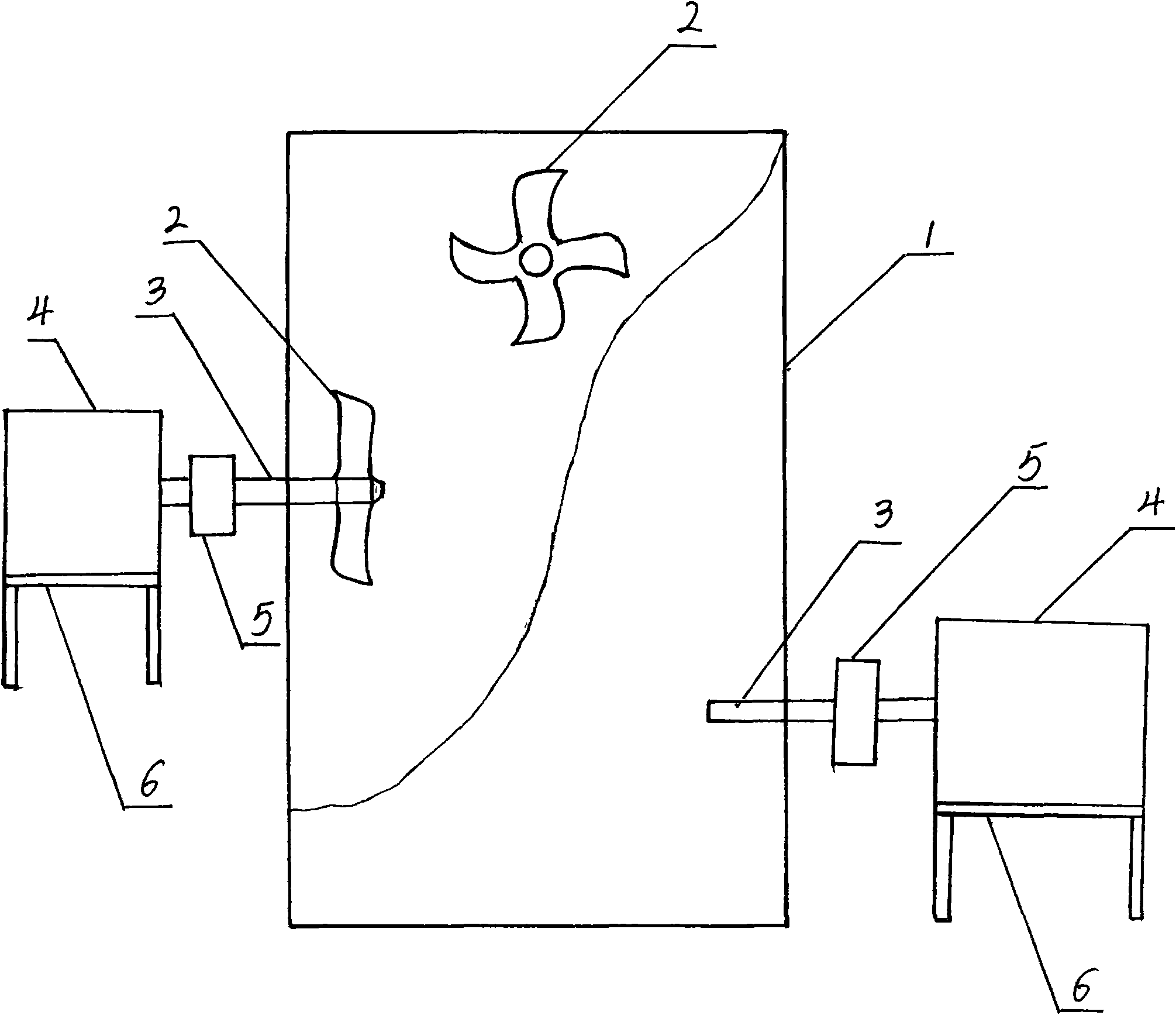

[0029] Wind energy utilization method and special device in a kind of mine exhaust duct of embodiment 3 of the present invention (see image 3 and Figure 4 ), it is designed based on the utilization of wind energy in a large coal mine exhaust duct, because the wind speed in a large coal mine exhaust duct is relatively high, generally around 16.4 m / s, and the diameter of the exhaust duct is more than 3 meters , usually the underground ventilation performance requirements are very strict, and there will be a certain amount of combustible gas in the exhausted wind. In order not to affect the exhaust air volume and make full use of the wind energy in the exhaust cylinder, it is designed as follows: in the original exhaust cylinder 1 Under the condition that the height is 3 meters, the height of the exhaust cylinder 1 is extended to 5 meters, and 4 power generating devices are evenly spirally arranged around the exhaust cylinder 1 . The impeller shaft hole is set at the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com