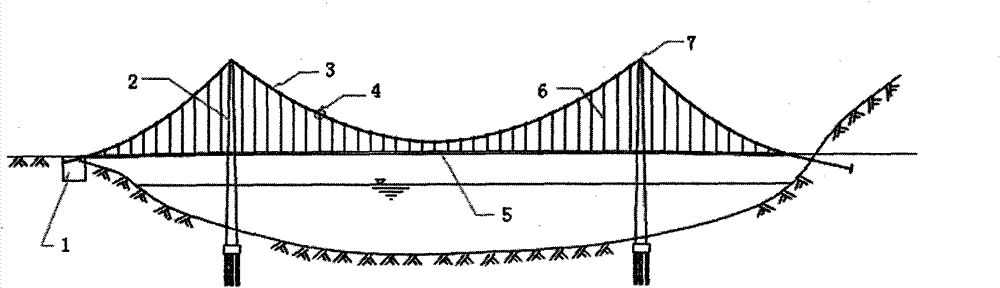

Casting method of pin-jointed cable clamp for lifting lug of suspension bridge

A technology of suspension bridge and pin connection, which is used in casting molding equipment, casting molds, casting mold components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

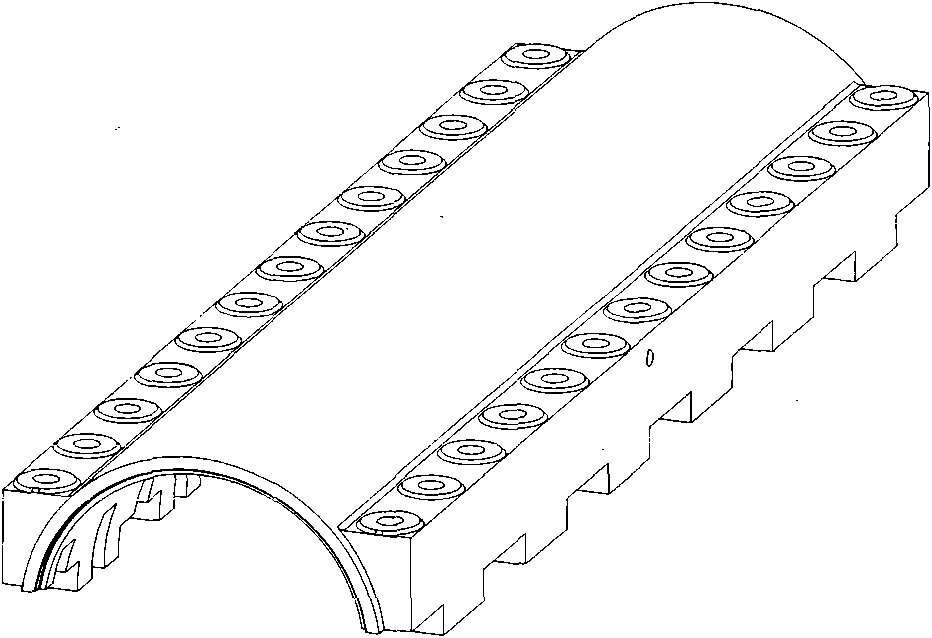

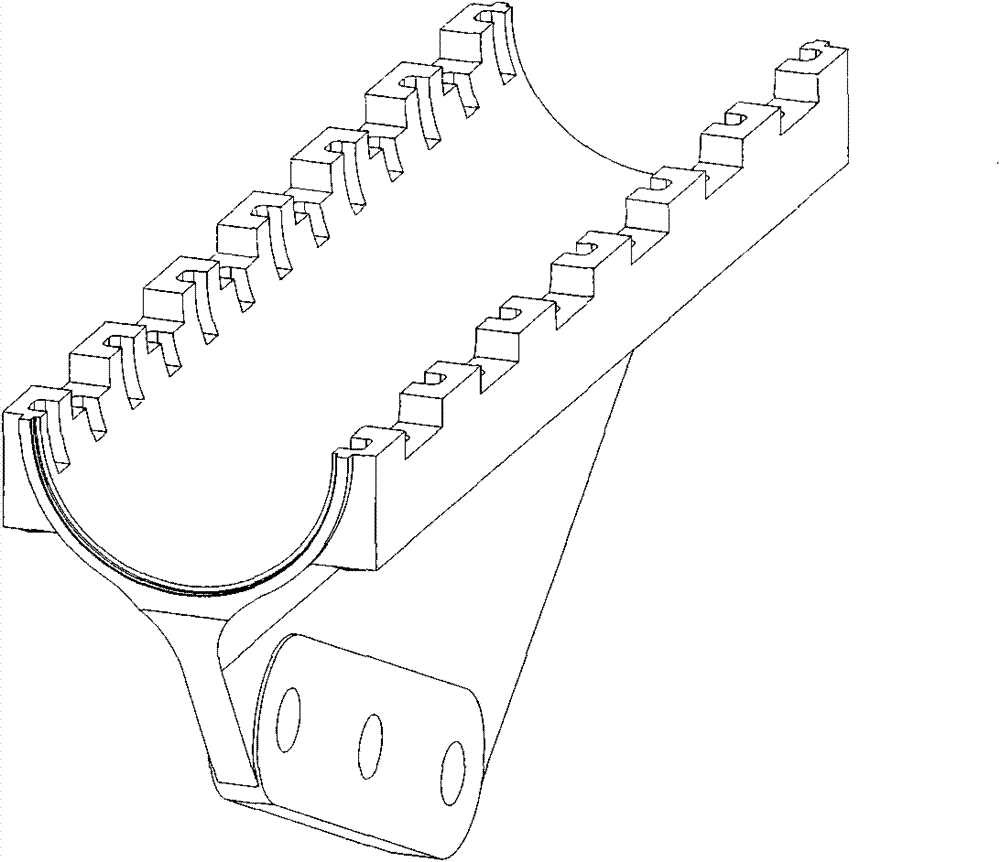

[0043] Combine below Figure 6~Figure 11 To further describe the specific implementation of the present invention, it should be noted that this embodiment is descriptive and not restrictive, and cannot be used to limit the protection scope of the present invention.

[0044] In this embodiment, the ZG20Mn material is used to cast the cable clamp. The specific dimensions of the lug-type cable clamp are: the cable clamp is 3 meters long, 1.1 meters wide, the cable hole diameter is 0.8 meters, and the minimum wall thickness is 40 mm.

[0045] (1) Model making. According to the upper and lower parts of the ear-type cable clamp 4, model drawings are made respectively, and then the models are made accordingly. After the models are dried, the surface is polished to make the roughness reach more than Ra100.

[0046] (2) Modeling. According to the upper and lower parts of the ear-type cable clamp 4, the plan drawings are respectively made, and then the casting bodies of the upper and lower p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com