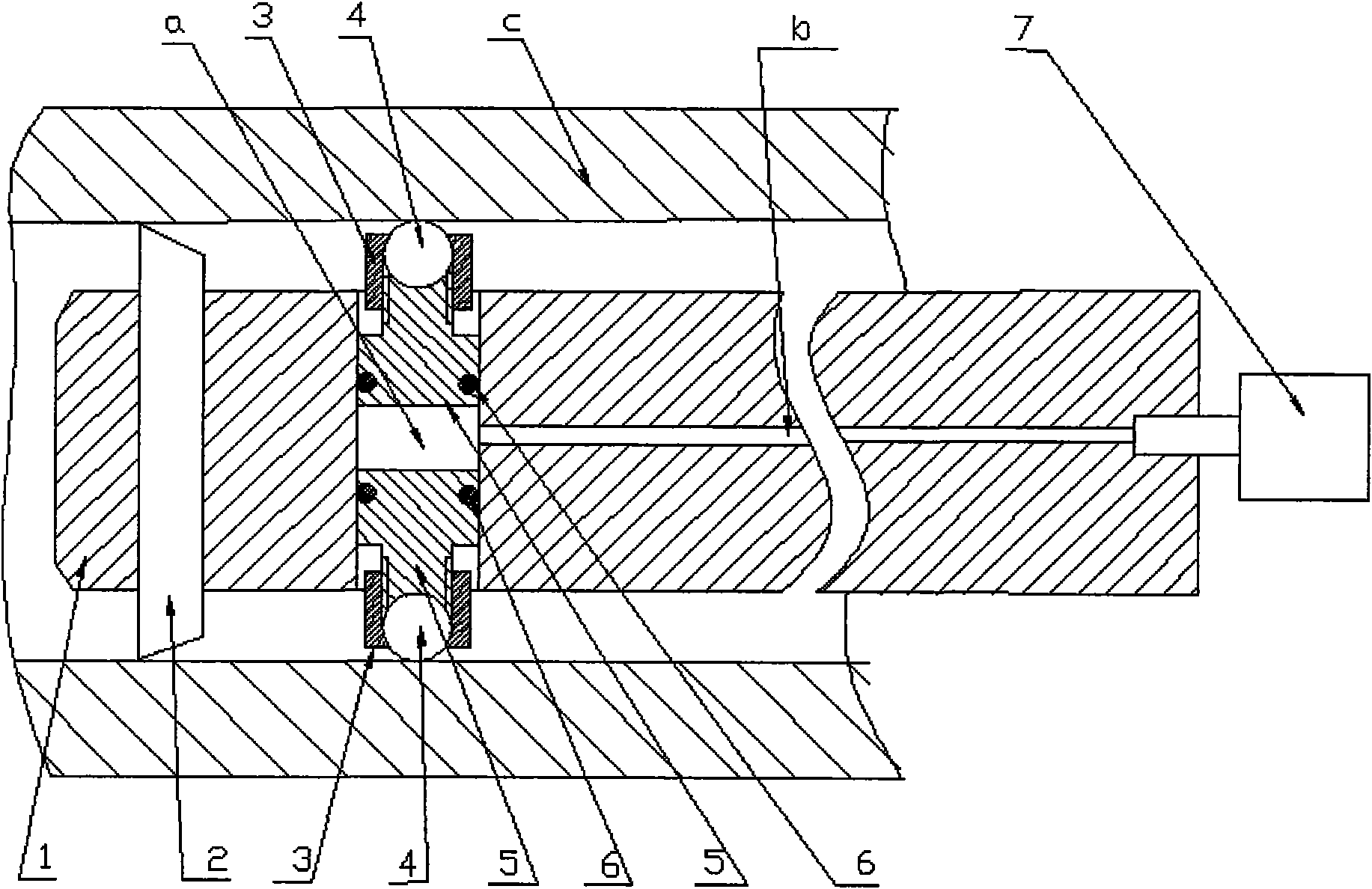

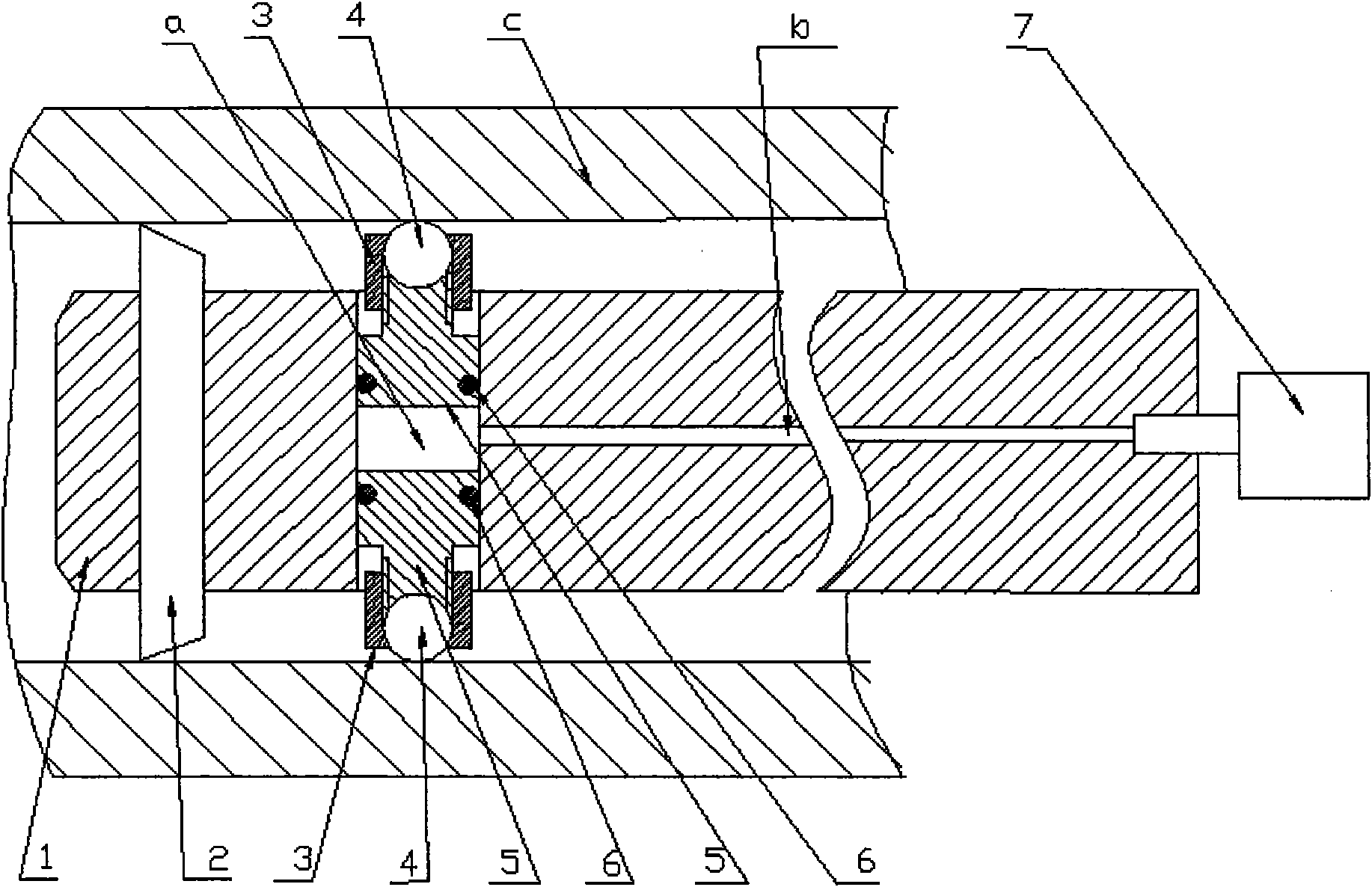

Novel boring cutter bar with entire rolling function

A boring tool bar and rolling technology, applied in the direction of boring bar, etc., can solve the problems of reduced hole quality and chipping, and achieve the effects of high processing quality, preventing tool chipping, and enhancing steel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] On the top of the cutter body (1), make a hole a perpendicular to its axis to make a channel b on the axis of the cutter body (1), and make it communicate with the hole a. Put the two pistons (5) into the Install the sealing ring (6), and at the same time correctly install it in the through hole a, install the ball (4) in the concave spherical surface of the head of the piston (5), and fix it with the ball pressing cap (3), and rotate the joint (7) Install with the mouth of the end channel b of the tool holder body (1). During work, the boring tool (2) firstly performs boring processing on the hole, and then the pressure source is passed into the rotary joint (7), and the pressure source enters the pressure chamber a through the channel b to push the piston to open, and the piston (5) pushes the ball (4 ) is tightly pressed on the inner hole wall of the workpiece c, and rolls the inner hole wall of the workpiece c with the rotation of the tool body (1), and due to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com