Abrasive profile cutting machine

A cutting machine and profile technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of rising temperature of the cutting surface, easy falling off of diamond grains, and reduced work efficiency, so as to reduce the risk of motor damage , Provide work efficiency and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

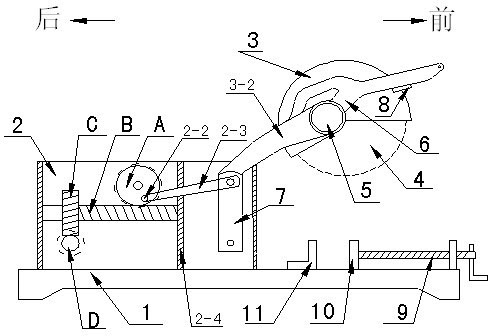

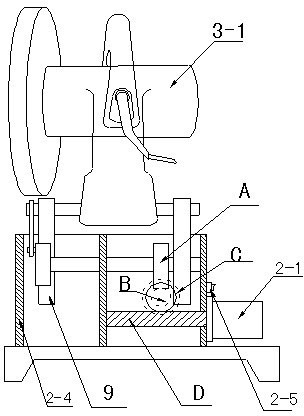

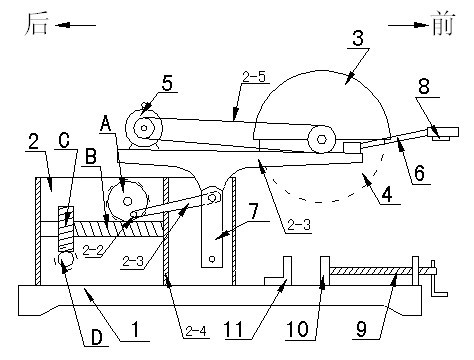

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Referring to the legend, a grinding wheel profile cutting machine includes a machine base 1, a front and rear driving mechanism 2 and a cutting machine 3, and is characterized in that: the cutting machine 3 is equipped with a driving motor 5 for driving the cutting grinding wheel sheet 4 to work, and the cutting machine The movable end of the cutting machine 3 is provided with a control handle 6 to facilitate its up and down swing, and the base 1 is hinged to the bottom end of the cutting machine 3 through the driving part 7 of the front and rear driving mechanism 2 .

[0012] In order to facilitate the forward and backward movement of the front and rear drive mechanism, the front and rear drive mechanism 2 includes a motor 2-1, a worm and a worm wheel, an eccentric shaft 2-2 and a connecting rod 2-3 connected to the end face of the worm wheel A, and a rocker arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com