Dual-purpose portable closing machine of single-needle single-line and double-needles double-lines

A sealing machine and single-thread technology, applied in the direction of cloth feeding mechanism, pocket sewing machine, sewing machine components, etc., can solve the problems of easy thread jumping, easy leaking items, easy leakage of powder products, etc., and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

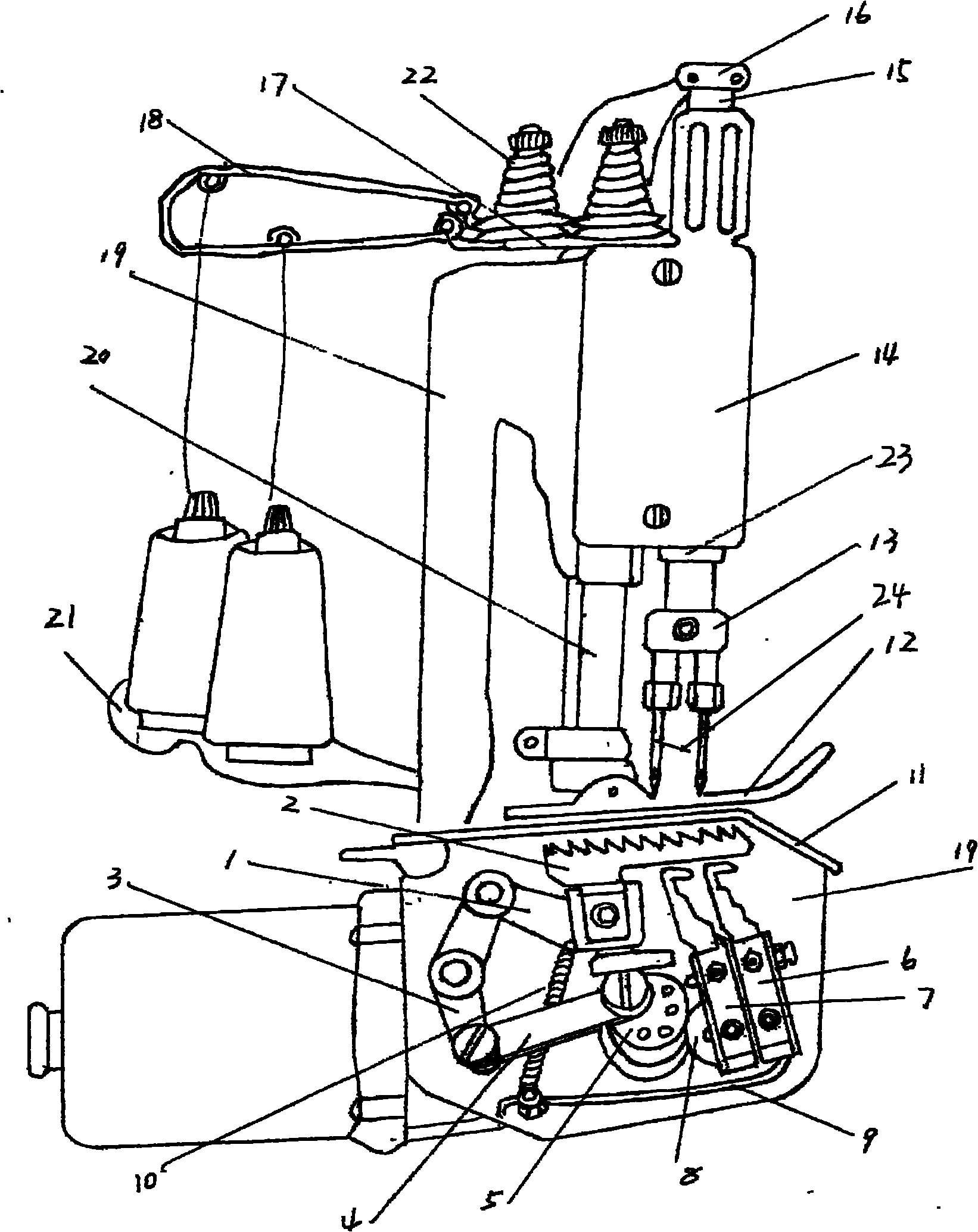

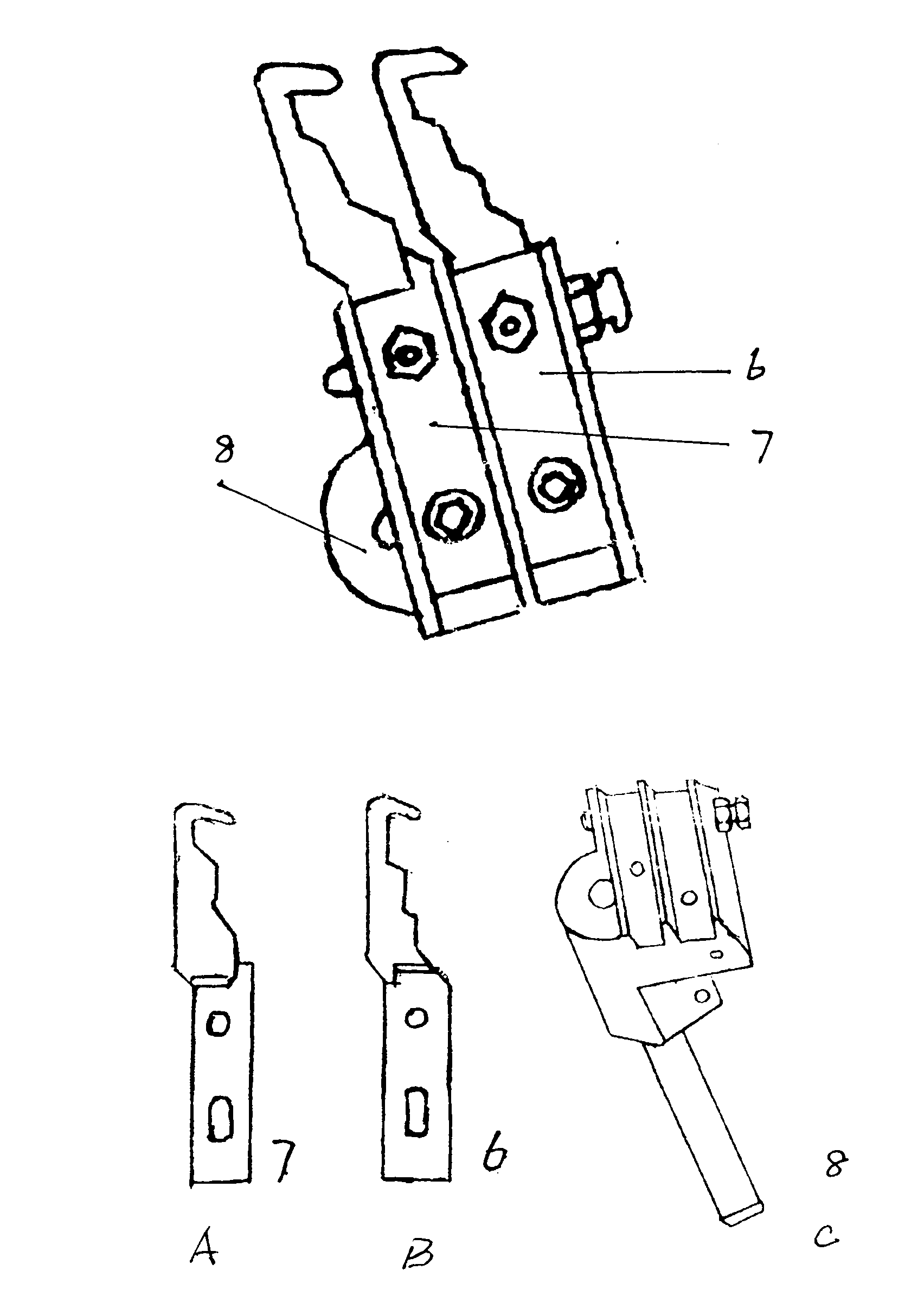

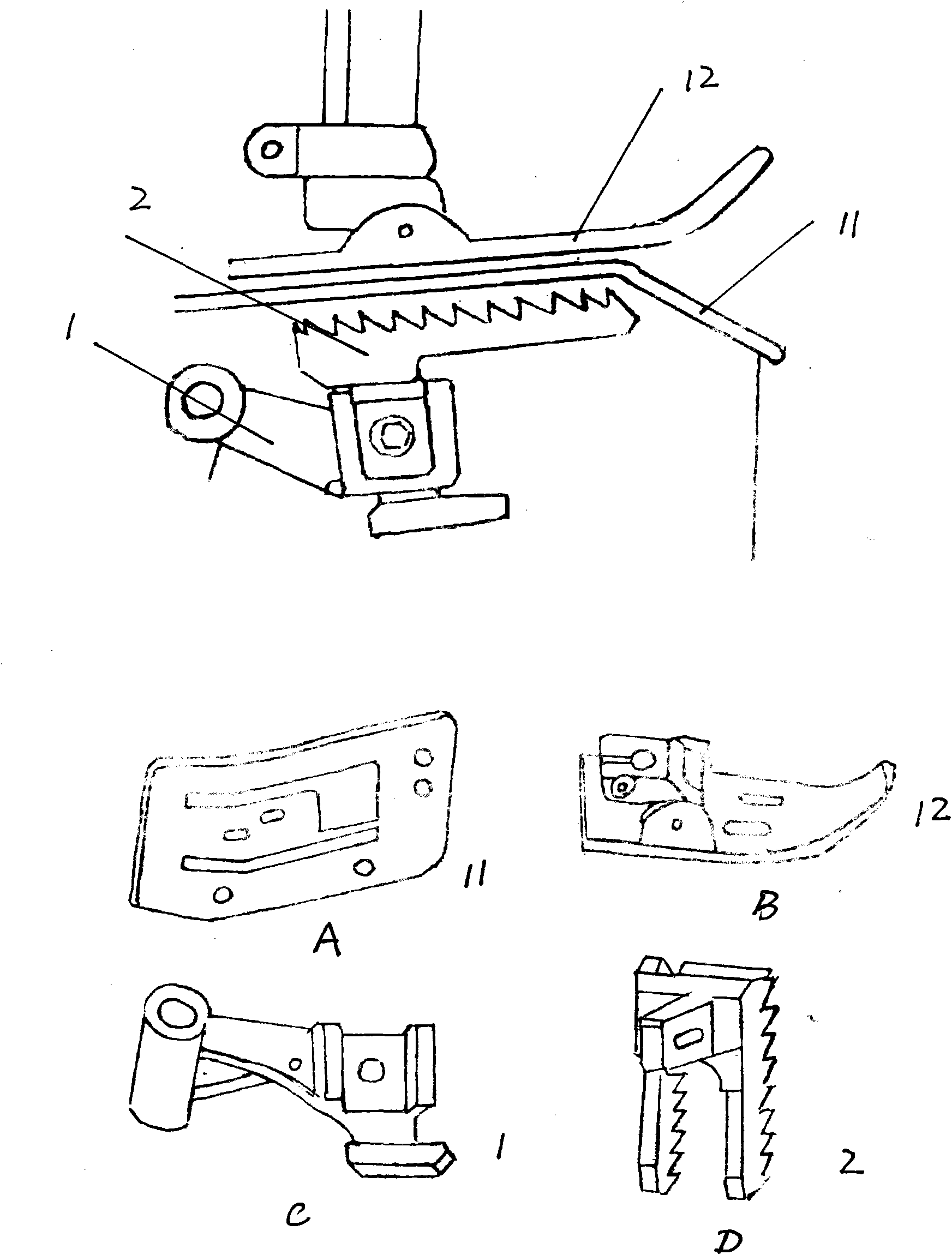

[0010] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown:

[0011] In the present invention, the left hook needle 7 and the right hook needle 6 are fixed in the groove of the hook frame 8, the hook frame 8 is connected to the main shaft 5 in transmission, the feeding tooth 2 is fixed in the groove of the tooth frame 1, and the tooth frame 1 is above the cam surface of the main shaft 5 The main shaft is directly driven and connected with the feeding connecting rod 3. The needle plate 11 is installed on the machine body 19, the presser foot 12 is fixed on the lower end of the pressing rod 20, and the needle clamp 13 is installed on the lower end of the needle bar 15. The left and right needles 24 are inserted into the needle clamp respectively. 13, the panel 14 is installed above the front of the body 19, the needle bar 15 and the needle bar connecting shaft 25 are connected and sleeved in the needle bar sleeve 23, the needle bar passing thread 16 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com