R125 near critical circulating high temperature heat pump unit

A R125, high temperature heat pump technology, used in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as waste, and achieve the effect of improving efficiency, simple process and small pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

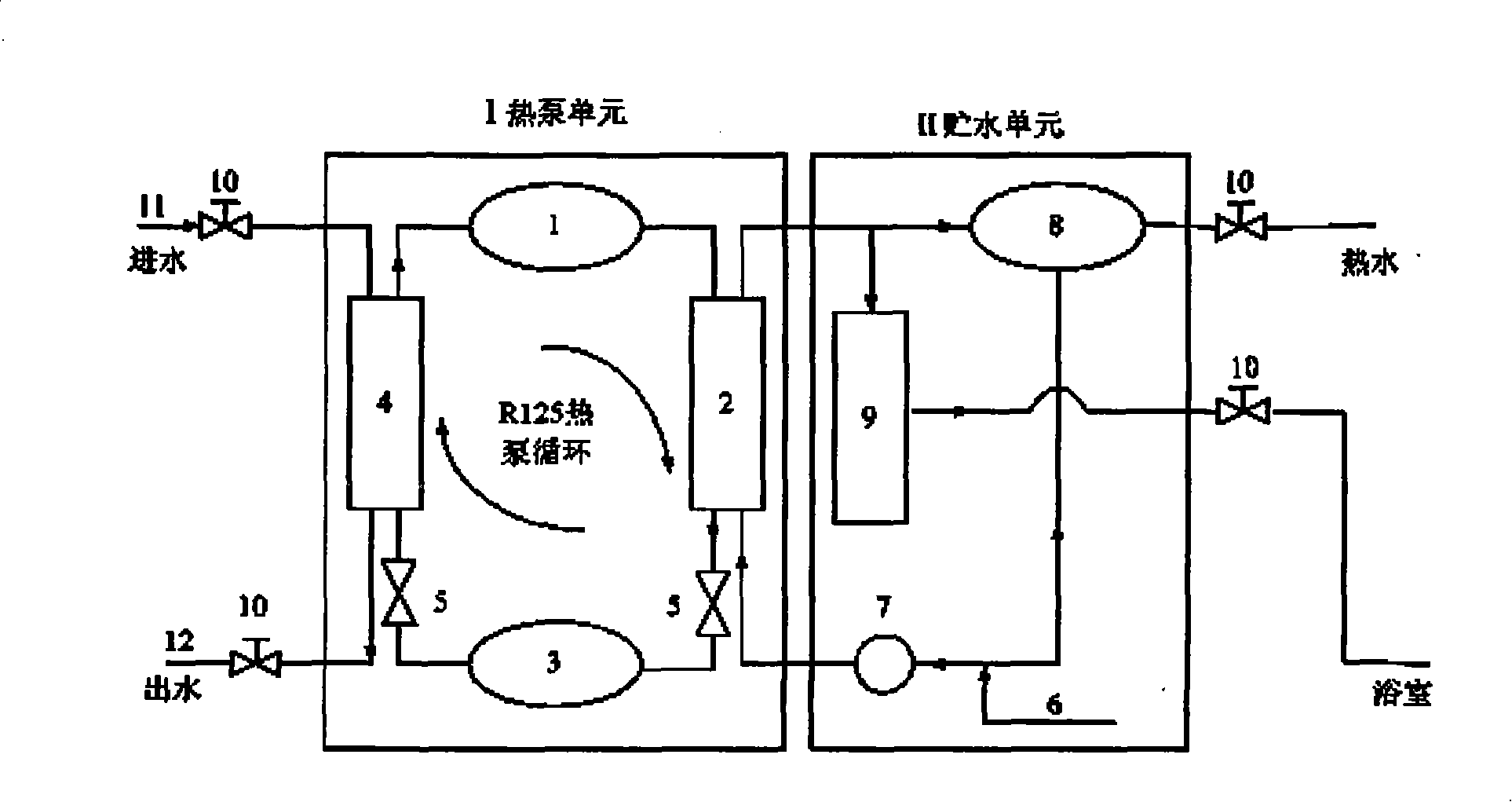

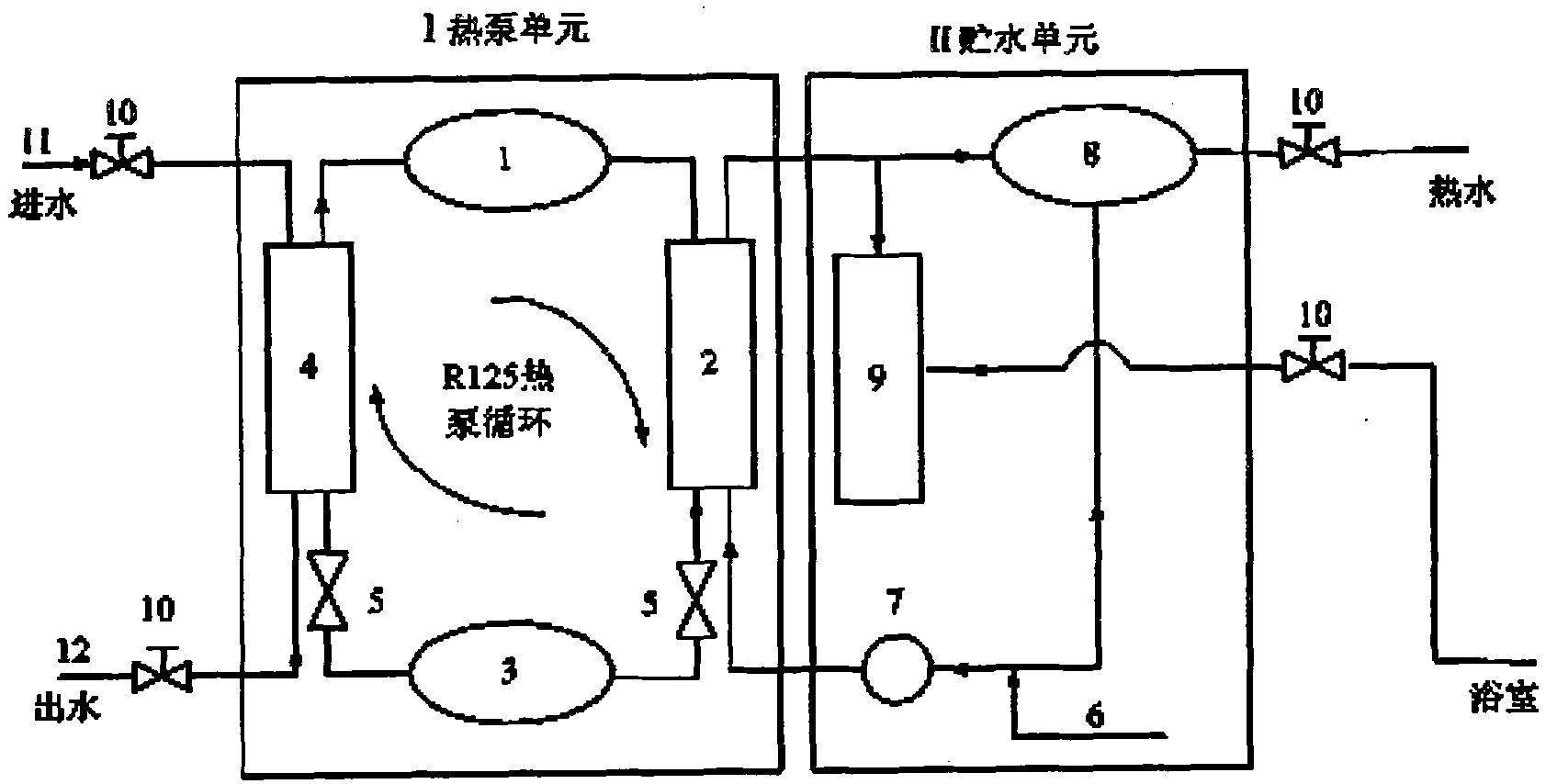

[0015] Such as figure 1 As shown, the present invention includes a heat pump unit I and a water storage unit II. The heat pump unit I is a closed loop formed by connecting a compressor 1, a condenser 2, a liquid reservoir 3, and an evaporator 4 sequentially through copper pipes. In the heat pump unit A throttling valve 5 is installed on the copper pipe between the condenser and the liquid reservoir, and the liquid reservoir and the evaporator to form a double throttling structure. The heat exchange channel of the evaporator 4 is connected with a valve 10 The water inlet pipe 11 and the water outlet pipe 12 used as chilled water for air conditioning. In the water storage unit II, the main water pipe 6 is connected to the water inlet of the heat exchange channel of the condenser 2 through the water pump 7, and the water outlet of the heat exchange channel of the condenser 2 is connected to the cold water pipeline through the water mixing valve 8, after mixing The pipeline is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com