Protection device of suction type optical disk drive

A technology for protection devices and optical disc drives, which is applied in the direction of recording carrier guidance, instruments, and recording information storage, and can solve the problems of increasing the force of the chute 3, troubles in adjusting the driving force, and consuming manufacturing man-hours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to achieve the above-mentioned purpose, the technical means adopted and their effects related to the present invention are listed below as preferred embodiments, and are described as follows in conjunction with the accompanying drawings.

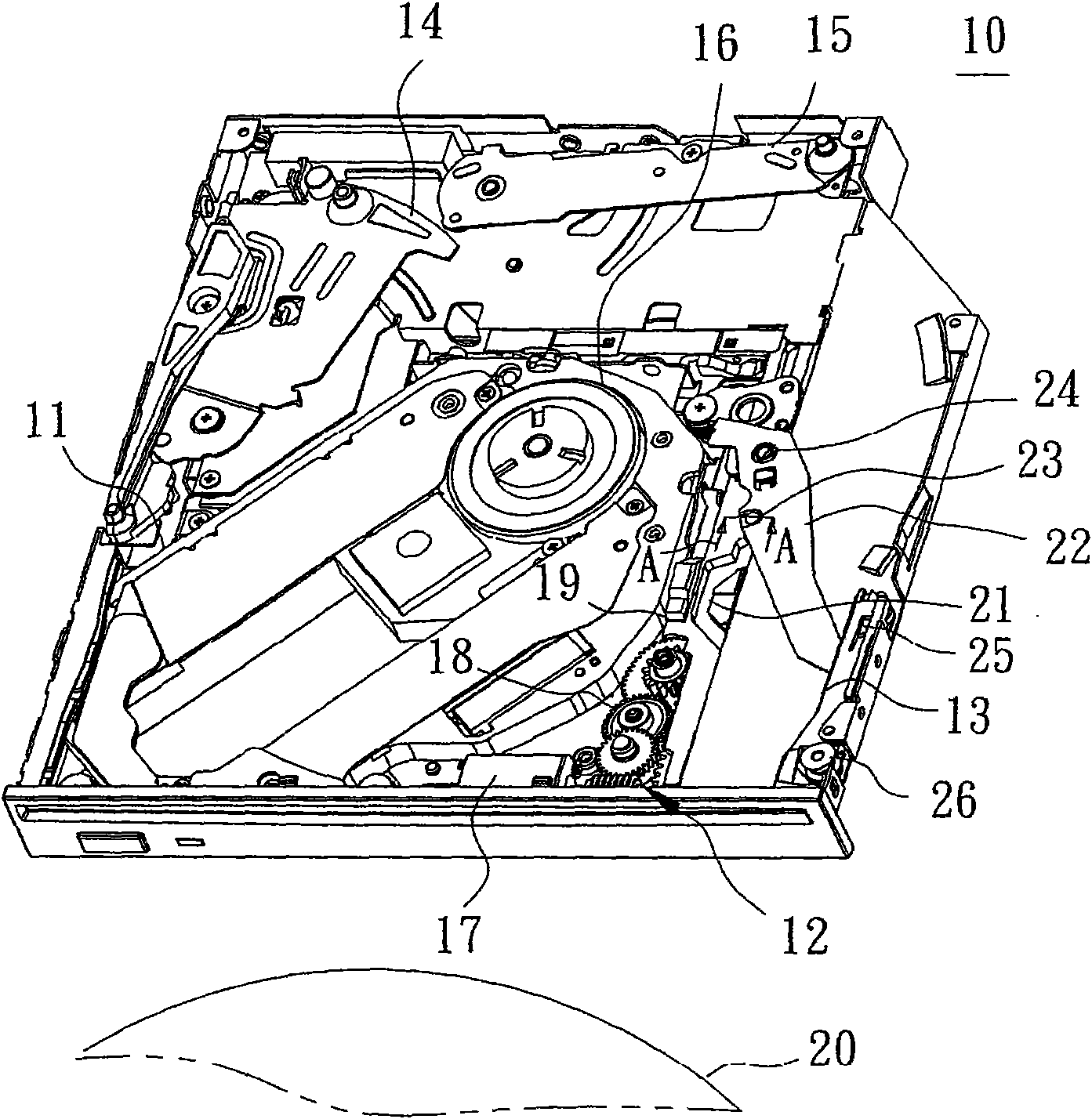

[0049] Please refer to figure 2 , is the slot-in optical disk drive 10 provided with the protection device of the present invention. The slot-in optical disc drive 10 includes a core 11 , a power unit 12 , a film advancing guide rod 13 , a film ejecting guide rod 14 , a positioning guide rod 15 and the like. The core 11 is disposed in the hollow of the slot-in optical disc drive 10 , and one end of the core 11 is provided with a spindle motor 16 and is located in the center of the slot-in optical disc drive 10 . Adjacent to the movement 11, a power unit 12 is arranged, and the power unit 12 utilizes a transmission motor 17 to rotate the gear set 18 to drive the slider 19 to move back and forth along the side of the slot-in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com