Pentane type composite polyether and composition containing same, rigid polyurethane rigid foam and application thereof

A combination of polyether and pentane-type technology, applied in the energy industry, solar thermal devices, solar thermal power generation, etc., can solve the problems of poor compatibility and unsuitable solar water heaters, and achieve good compatibility, obvious environmental protection advantages, Good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Formula of cyclo / isopentane combined polyether:

[0039] Polyether polyol 8210H 7 parts, polyether polyol SA4603 parts, silicone foam stabilizer B8462 0.2 parts, N,N,N`,N``,N```-pentamethyldiethylenetri 0.02 parts of amine, 0.20 parts of triethylenediamine, 0.08 parts of potassium isooctanoate, 0.7 parts of cyclopentane, 0.3 parts of isopentane and 0.10 parts of deionized water.

[0040] 2. The preparation method of the cyclo / isopentane type combined polyether: according to the formula of the cyclo / isopentane type combined polyether, the above components are stirred at room temperature at a speed of 500 revolutions per minute for 2 hours, and the material is released.

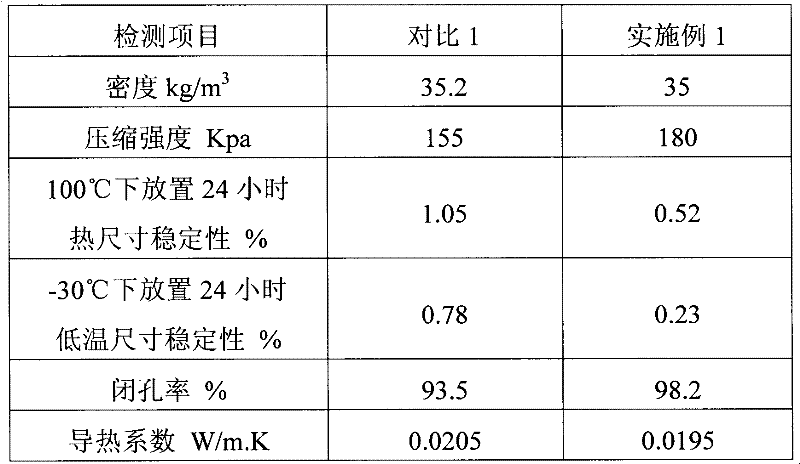

[0041] 3. Preparation of polyurethane rigid foam insulation material: the cyclo / isopentane combined polyether and isocyanate are reacted at 20°C at a mass ratio of 1:1.15 to obtain a foam density of 35kg / m 3 Polyurethane rigid foam insulation material for solar energy. The physical and chemical properties of...

Embodiment 2

[0048] 1. The formula of cyclopentane type combined polyether:

[0049] Polyether polyol 8210H 8 parts, polyether polyol SA4602 parts, silicone foam stabilizer L6900 0.3 parts, N,N,N`,N``,N```-pentamethyldiethylenetri 0.03 part of amine, 0.15 part of triethylenediamine, 0.12 part of potassium acetate, 1.0 part of cyclopentane and 0.05 part of deionized water.

[0050] 2. Preparation method of cyclopentane-type combined polyether: according to the formula of cyclopentane-type combined polyether, stir the above-mentioned components at room temperature at a speed of 500 revolutions per minute for 2 hours, and then discharge the materials.

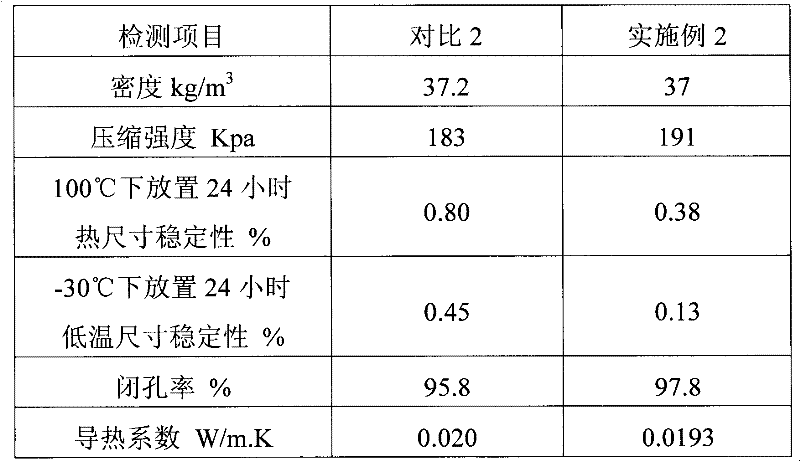

[0051] 3. Preparation of polyurethane rigid foam insulation material: the cyclopentane combined polyether and isocyanate are reacted at a mass ratio of 1:1.0 at 25°C to obtain a foam density of 37kg / m 3 Polyurethane rigid foam insulation material for solar energy. The physical and chemical properties of the polyurethane rigid foam are shown in Table ...

Embodiment 3

[0058] 1. The formula of cyclopentane type combined polyether:

[0059] Polyether polyol 8210H 6 parts, polyether polyol SA4604 parts, silicone foam stabilizer L6900 0.2 parts, N,N,N`,N``,N```-pentamethyldiethylenetri 0.02 part of amine, 0.1 part of triethylenediamine, 0.1 part of potassium oleate, 1.3 part of cyclopentane and 0.08 part of deionized water.

[0060] 2. Preparation method of cyclopentane-type combined polyether: according to the formula of cyclopentane-type combined polyether, stir the above-mentioned components at room temperature at a speed of 500 revolutions per minute for 2 hours, and then discharge the materials.

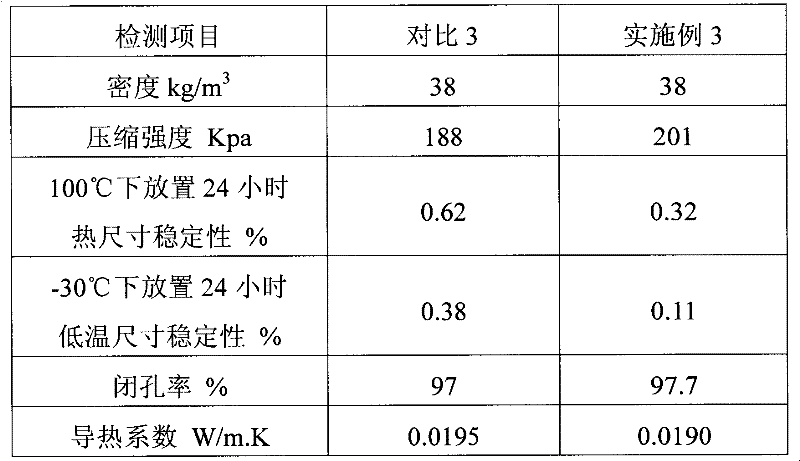

[0061] 3. Preparation of polyurethane rigid foam insulation material: the mass ratio of the above cyclopentane-type combined polyether and isocyanate is 1:1.30, and the foam density is 38kg / m 3 Polyurethane rigid foam insulation material for solar energy.

[0062] 4. Comparison 3 Preparation of polyurethane rigid foam insulation material:

[0063] 1. HCFC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com