Combustion system of high-power capacity type gas water heater and combustion method thereof

A technology for gas water heaters and combustion systems, which is applied to fluid heaters, lighting and heating equipment, etc., can solve problems such as increased system costs, large flue resistance, and hidden dangers to system safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

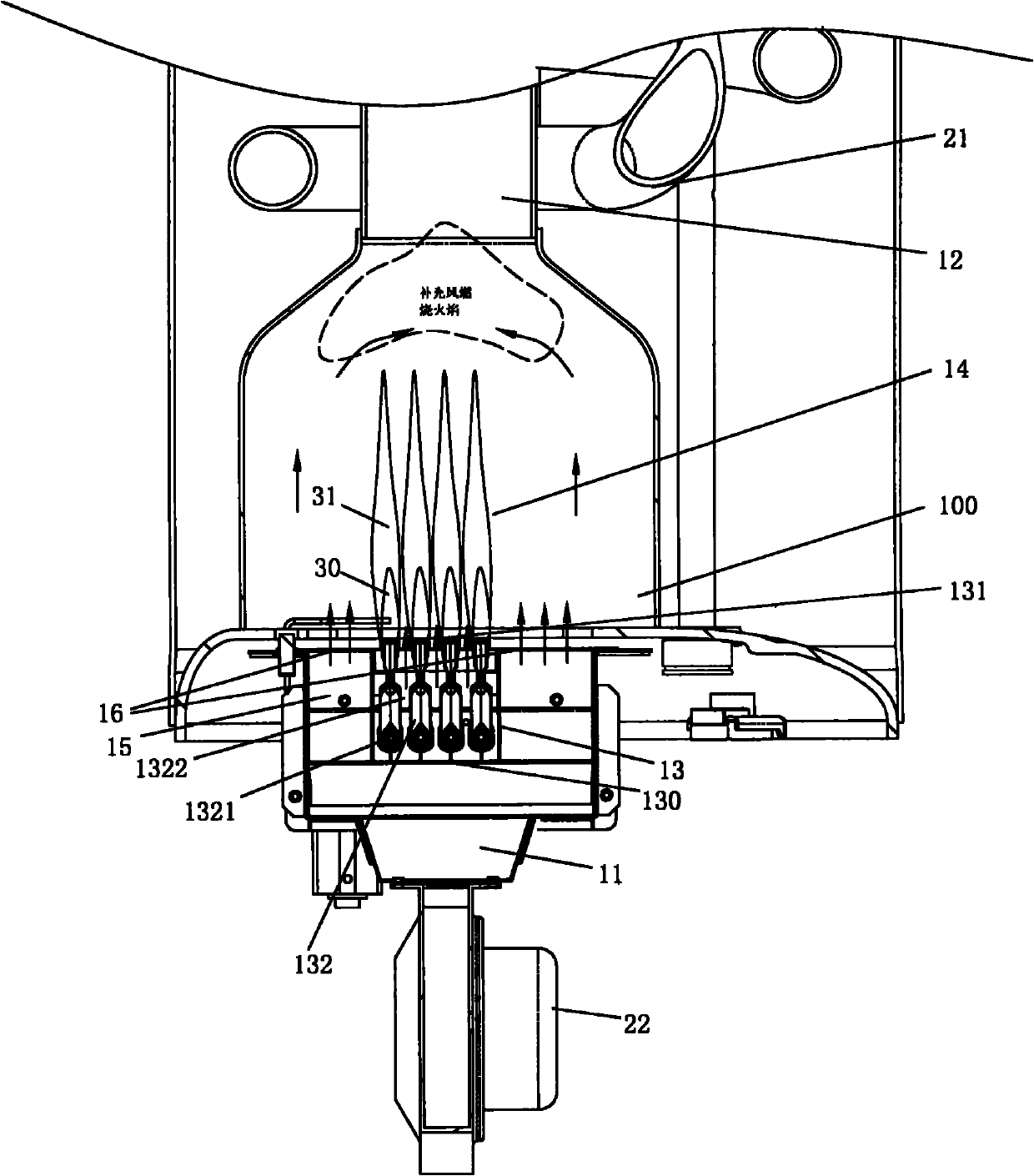

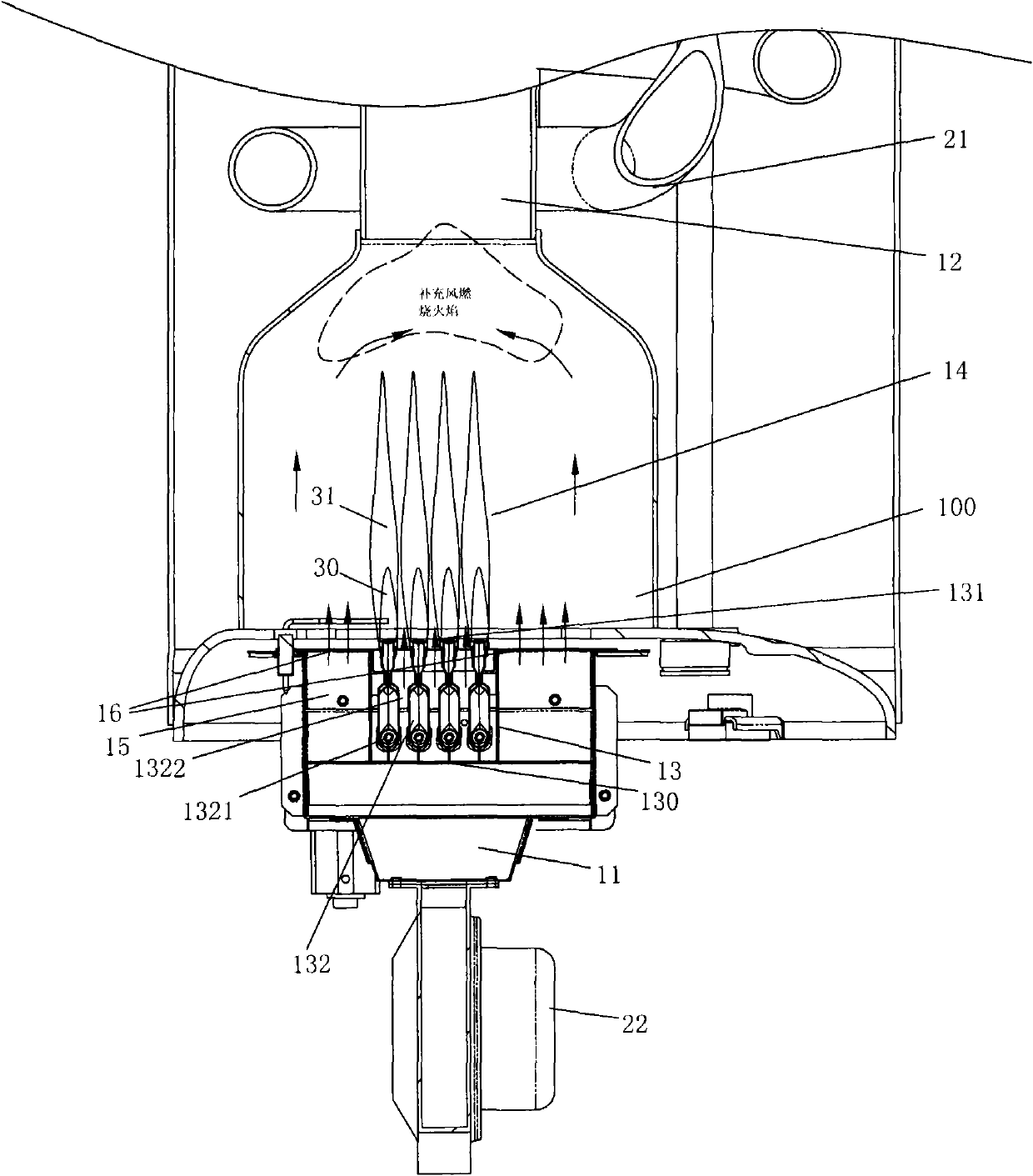

[0017] Such as figure 1 As shown, the combustion system includes a chamber 100, the chamber 100 has an air receiving port 11 connected to the fan 22 and a flue gas outlet 12 leading to the heat exchange assembly 21, and there is a The combustion space 14 for gas combustion and the space for installing the burner assembly 13 . The inlet 130 of the burner assembly 13 has an air intake passage communicated with the air receiving port 11, the outlet 131 of the burner assembly communicates with the combustion space 14 for gas combustion, and the combustion space 14 communicates with the flue gas outlet 12, and the periphery of the burner assembly 13 An air supplementary air channel 15 is provided between the inner side or the inner wall of the chamber 100 . The supplementary air channel 15 surrounds the entire burner assembly 13 , and its two ends communicate with the combustion space 14 and the air receiving port 11 respectively. An air distribution device or an orifice 16 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com