Gas turbine combustion chamber swirler and assembly

A gas turbine and swirler technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of smaller load adjustment range, poor combustion stability, combustion oscillation, etc., to prevent backfire, stable airflow, and stable burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

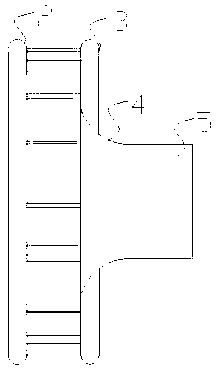

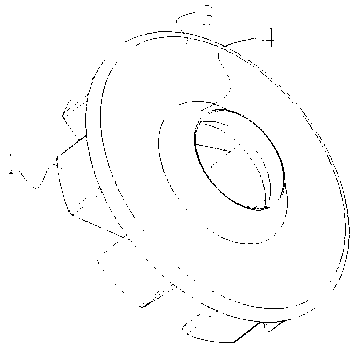

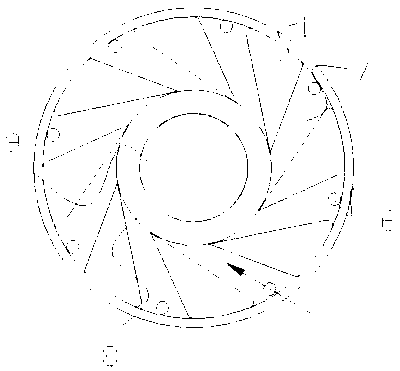

[0032] Such as figure 1 As shown in -4, a gas turbine combustor swirler and assembly of the present embodiment includes a swirler and a guide ring 4 and a premixing chamber 5 arranged downstream of the swirler air flow, and the guide ring 4 is located in the swirl Between the swirler and the premixing chamber 5, the swirler, the guide ring 4 and the premixing chamber 5 are integrally formed; the swirler is a radial swirler, including a plurality of swirl blades 1 arranged in a circle, and the swirl The top of the flow blade 1 is fixedly connected with the circular end plate 3, the bottom of the swirl blade 1 is connected with the burner end cover 2 by bolts, the burner end cover 2 is provided with a fuel nozzle assembly hole, and the burner end cover 2 and the circular end The plates 3 are set concentrically, and the circular end plate 3 is provided with a concentric center hole; the swirl blades 1 extend radially, and a swirl channel 7 extending along the direction of the ce...

Embodiment 2

[0035] Such as figure 1 -2 and Figure 5-6 As shown, a gas turbine combustor swirler and assembly of the present embodiment includes a swirler and a guide ring 4 and a premixing chamber 5 arranged downstream of the swirler air flow, and the guide ring 4 is located between the swirler and the swirler. Between the premixing chambers 5, swirlers, guide rings 4 and premixing chambers 5 are integrally formed; the swirlers are radial swirlers, including a plurality of swirl vanes 1 arranged in a circle, and the swirl vanes 1 The top is fixedly connected with the circular end plate 3, the bottom of the swirl vane 1 is bolted to the burner end cover 2, the burner end cover 2 is provided with a fuel nozzle assembly hole, the burner end cover 2 and the circular end plate 3 Set concentrically, the circular end plate 3 is provided with a concentric center hole; the swirl blades 1 extend in the radial direction, and a swirl channel 7 extending along the direction of the center hole is fo...

Embodiment 3

[0038] Such as figure 1 As shown in -4, a gas turbine combustor swirler and assembly of the present embodiment includes a swirler and a guide ring 4 and a premixing chamber 5 arranged downstream of the swirler air flow, and the guide ring 4 is located in the swirl Between the swirler and the premixing chamber 5, the swirler, the guide ring 4 and the premixing chamber 5 are integrally formed; the swirler is a radial swirler, including a plurality of swirl blades 1 arranged in a circle, and the swirl The top of the flow blade 1 is fixedly connected with the circular end plate 3, the bottom of the swirl blade 1 is connected with the burner end cover 2 by bolts, the burner end cover 2 is provided with a fuel nozzle assembly hole, and the burner end cover 2 and the circular end The plates 3 are set concentrically, and the circular end plate 3 is provided with a concentric center hole; the swirl blades 1 extend radially, and a swirl channel 7 extending along the direction of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com