STI structure and method of forming bottom void in same

A technology of isolation structure and shallow trench, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of inferior component performance, unpredictable, charge leakage, etc., and achieve the effect of good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

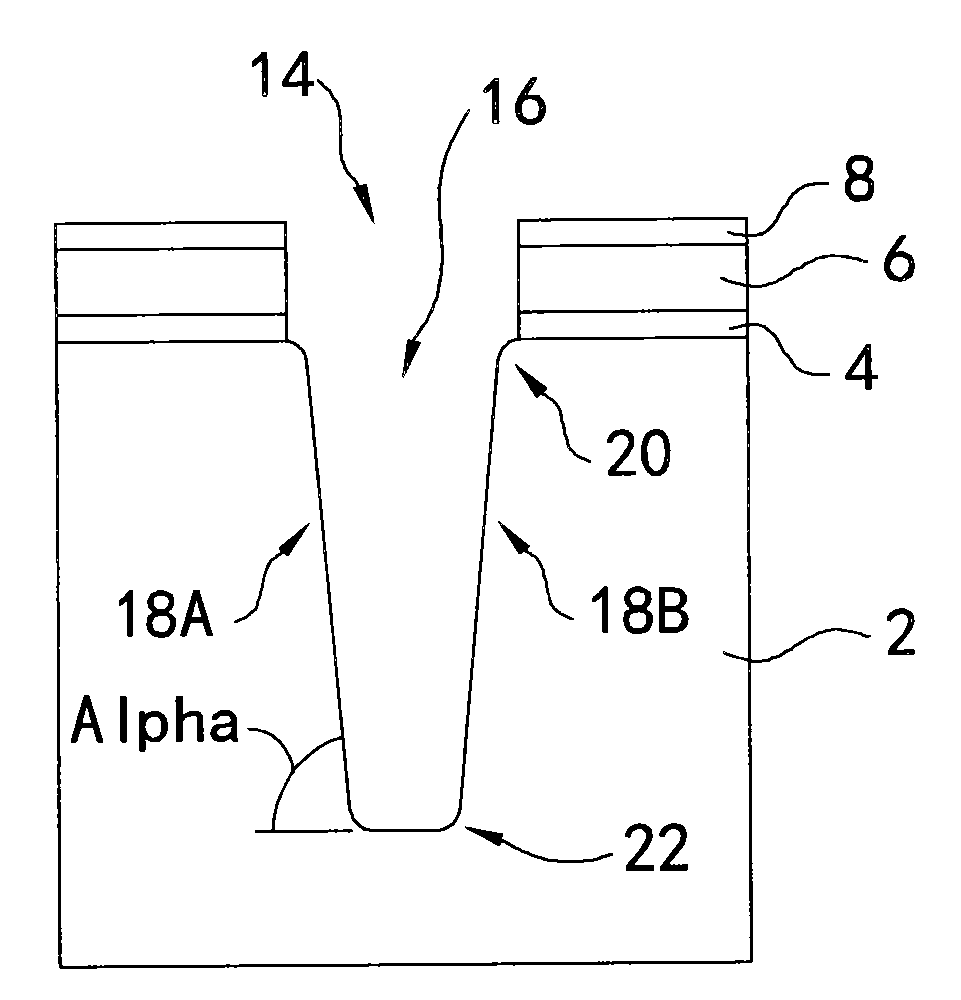

[0022] Although the embodiments of the present invention are particularly directed to shallow trench isolation (STI) structures, the techniques used in the embodiments of the present invention can be applied to other types of gap or hole filling processes in other integrated circuit processes. In addition, embodiments of the present invention are directed to grooves, gaps, etc. with large aspect ratios (for example: aspect ratios of 5 to 1, 6 to 1, 7 to 1, 8 to 1, 9 to 1, 10 to 1 , 11:1, 12:1 or greater aspect ratio).

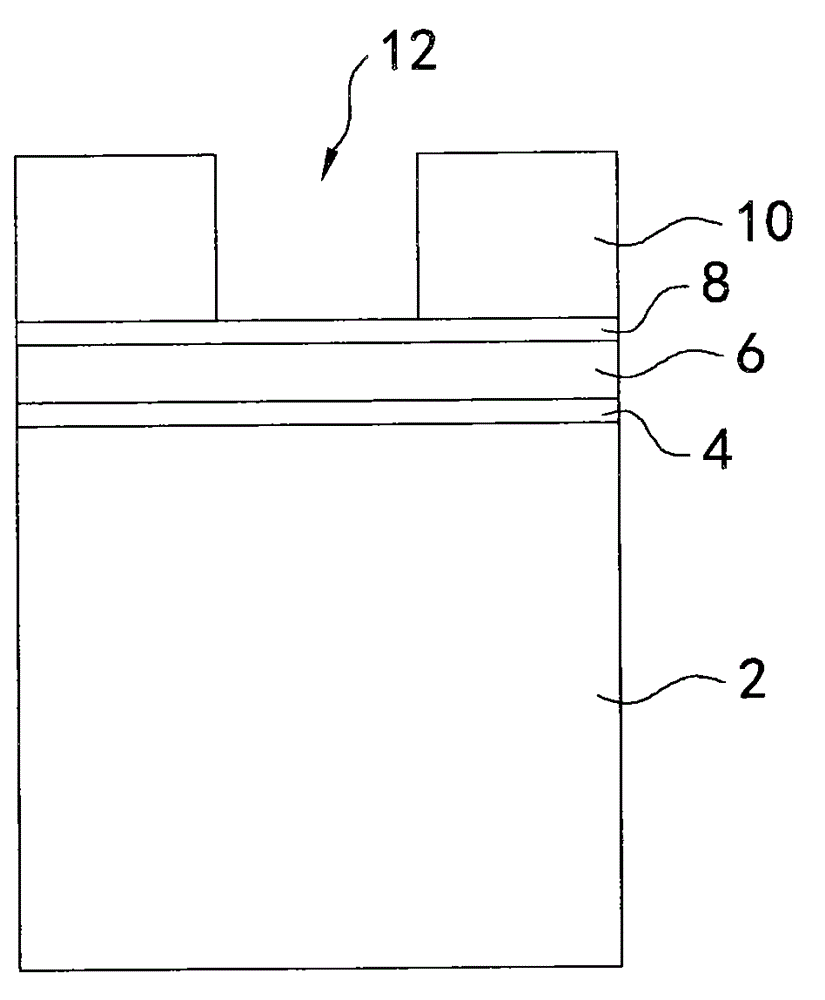

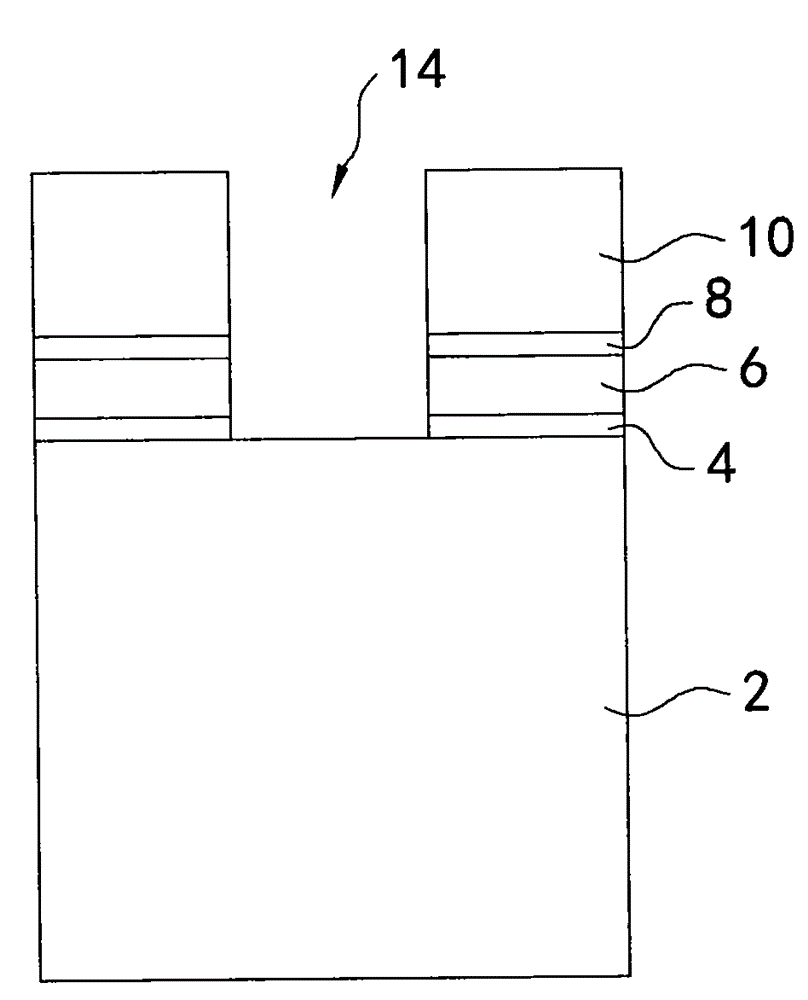

[0023] Figure 1 to Figure 6 It is a cross-sectional view of a structure in different process steps for forming a shallow trench isolation structure according to an embodiment of the present invention. However, the accompanying drawings of the present invention are only used to illustrate the embodiments of the present invention, rather than to limit the present invention. Changes and modifications, so the protection scope of the present invention should be as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com