Feedforward control method for intermediate-frequency lower twin-stage matrix converter

A matrix converter and feedforward control technology, which is applied in the direction of converting AC power input into AC power output, output power conversion devices, electrical components, etc. Correction coefficient correction, PWM cycle limit, can not be greatly improved and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

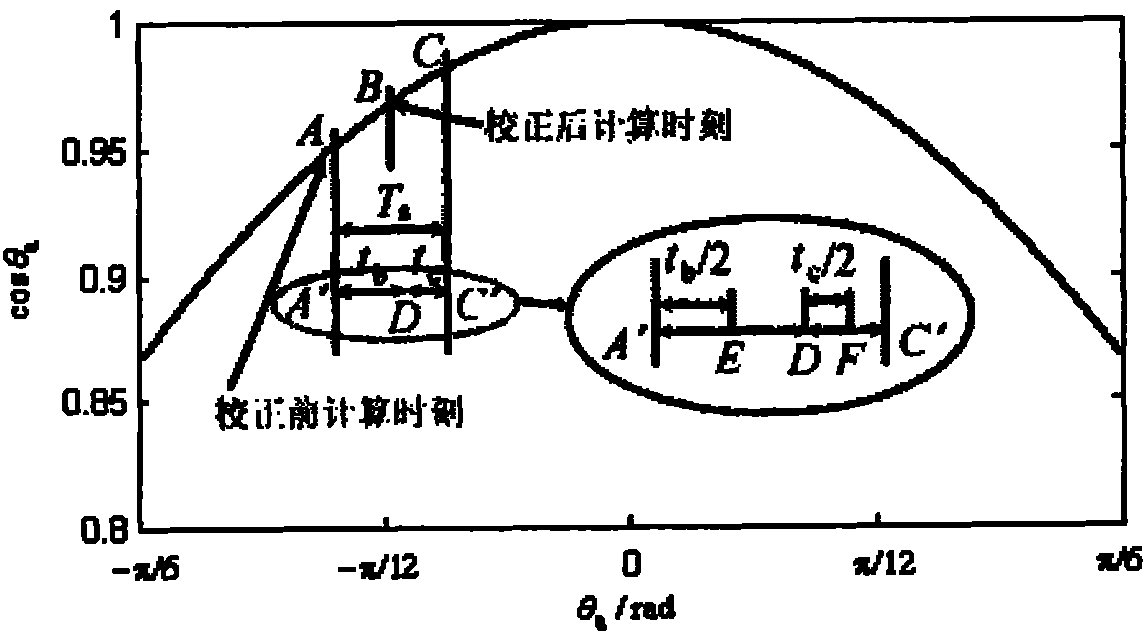

[0040] Such as figure 2 As shown, the dual-stage matrix converter consists of 18 power switches. Six bidirectional switches in the rectification stage form a three-phase rectifier bridge. Usually, each bidirectional switch is composed of two insulated gate bipolar transistors (IGBT) in reverse series. The inverter stage consists of 6 IGBTs to form a three-phase inverter bridge, which is exactly the same as the traditional three-phase inverter bridge topology, and the mature space vector modulation algorithm can be used to control the inverter stage.

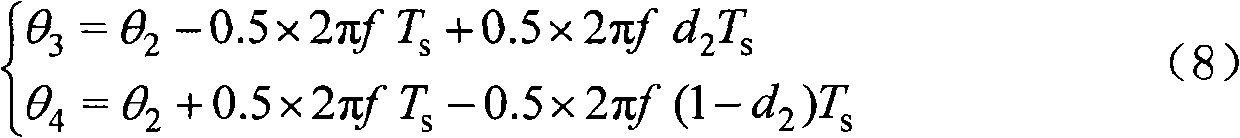

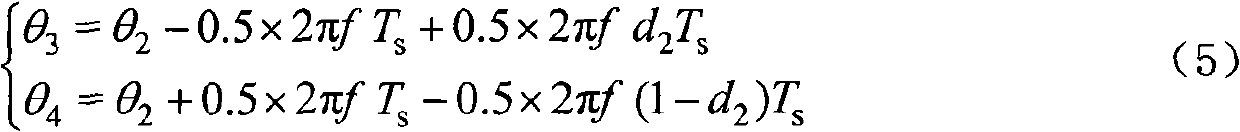

[0041] The control of the dual-stage matrix converter in the present invention finally needs to obtain the duty cycle of the rectification stage and the inverter stage, and the duty cycle of the rectification stage switch after eliminating the common mode error before correction is d 1 , the corrected rectifier stage switching duty cycle is d 2 , the duty cycle of the two switches of the inverter stage is d 3 and d 4 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com