Supporting type conveying appliance

A conveying device, a technology of horizontal conveying, applied in the directions of transportation and packaging, conveyor objects, furnaces, etc., can solve problems such as high cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

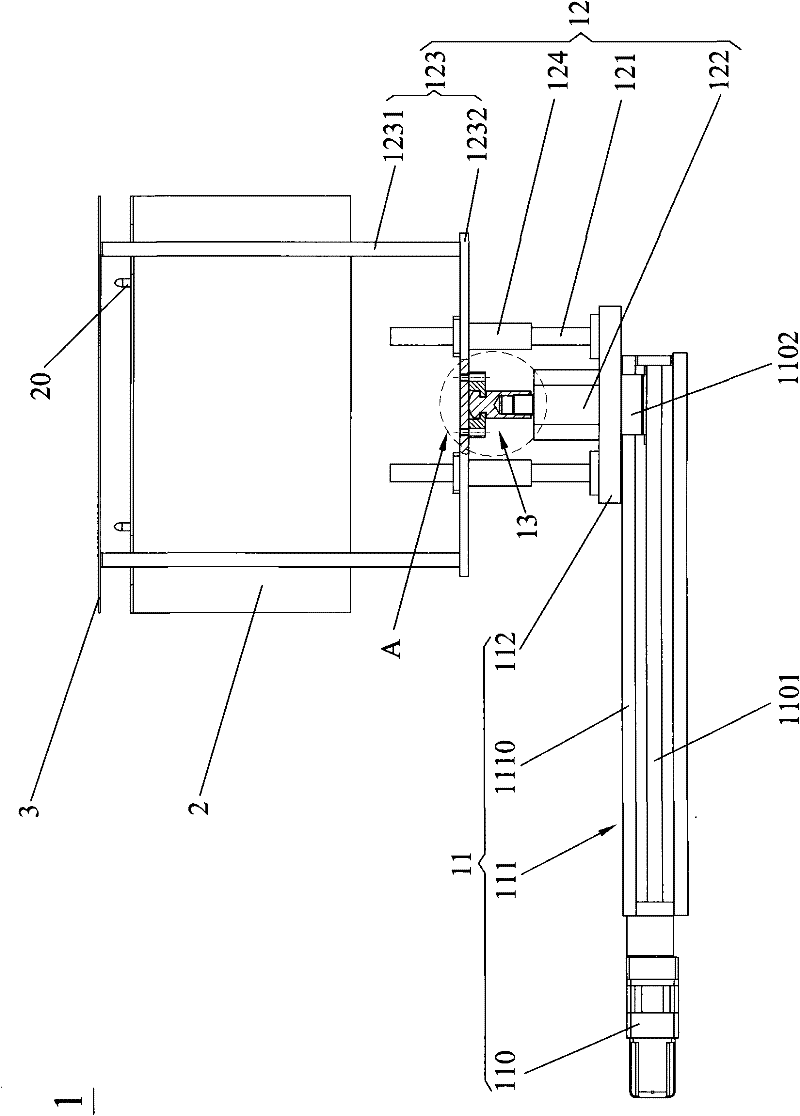

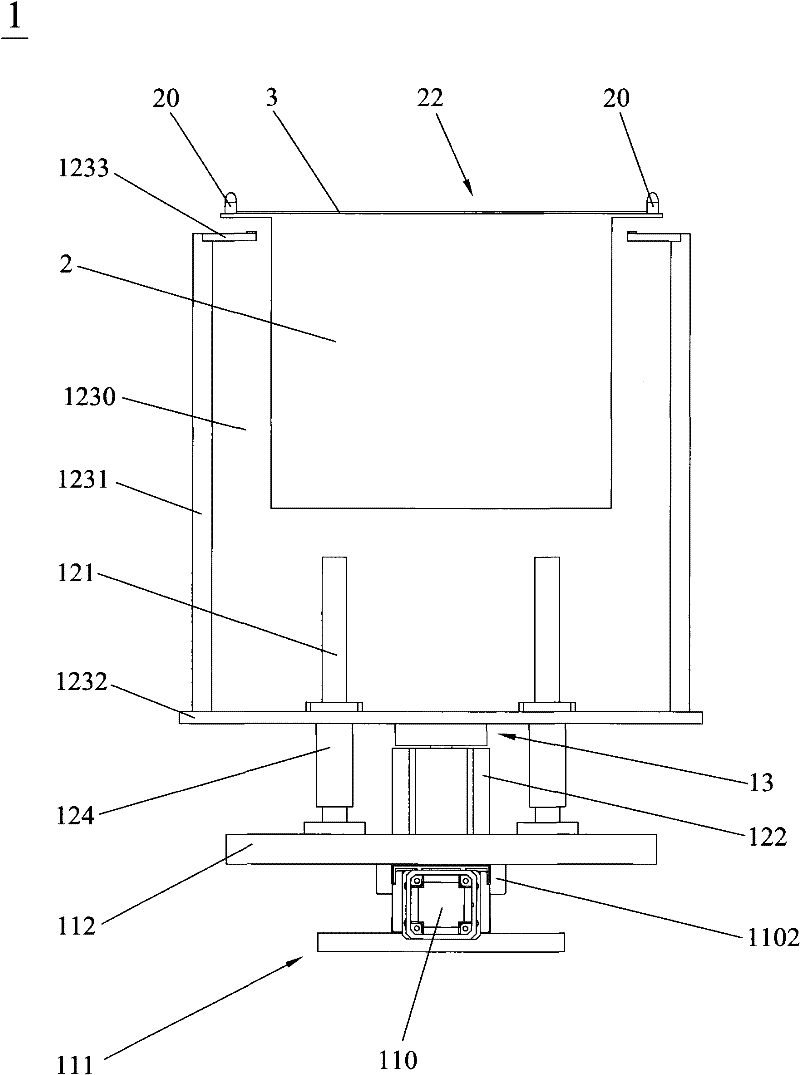

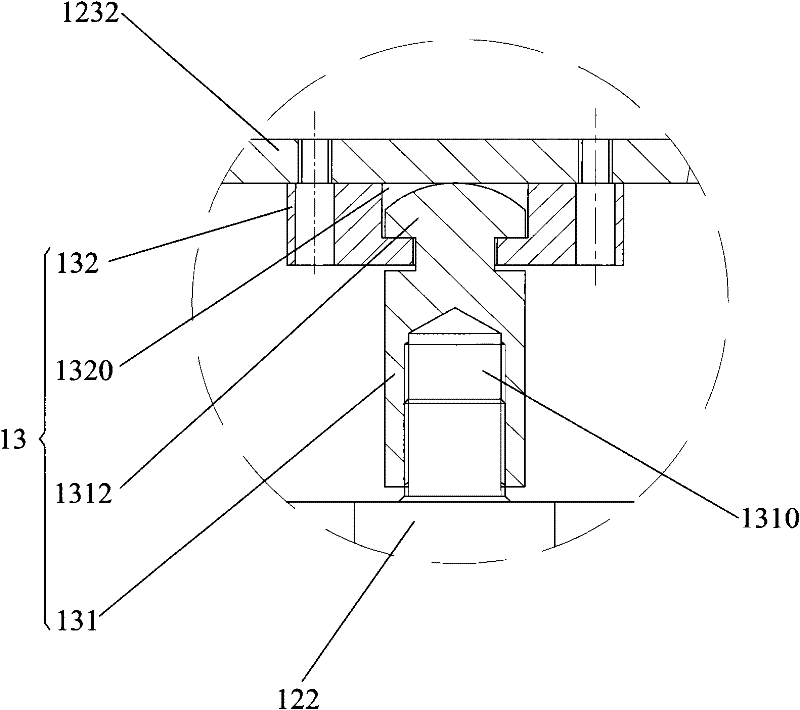

[0018] see Figure 1 to Figure 3, the consignment conveying device 1 of the present invention is used to lift and transport the thin plate workpiece 3 of the organic light emitting diode carried on the workbench 2 or convey the thin plate workpiece 3 to the workbench 2. Of course, the consignment conveyance device 1 of the present invention The conveying device 1 can also convey other types of thin plate workpieces. Wherein, the pallet conveying device 1 includes a horizontal conveying mechanism 11 and a vertical conveying mechanism 12 . The horizontal conveying mechanism 11 includes a horizontal driver 110 , a guide frame 111 and a carrying platform 112 . The guide frame 111 is arranged along the horizontal direction; the bearing table 112 is slidably assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com