Sewing machine

A technology for sewing machines and objects to be sewn, which is applied in the direction of sewing machine components, sewing equipment, and cloth feeding mechanisms. It can solve problems such as misalignment of the front edge of the cloth, and the inability to tangle the stitches of the sewing needle, and achieve the effect of accurate identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

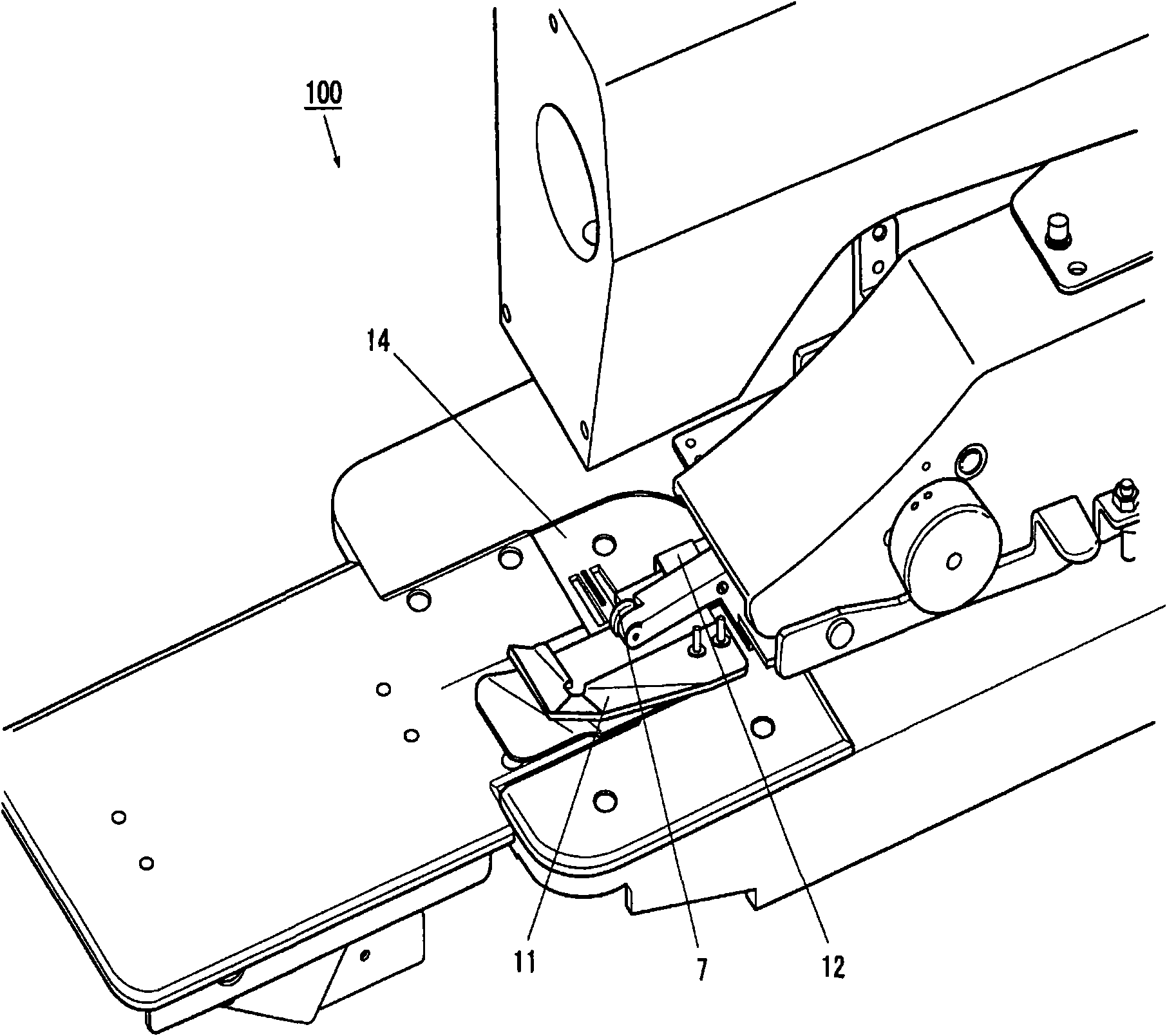

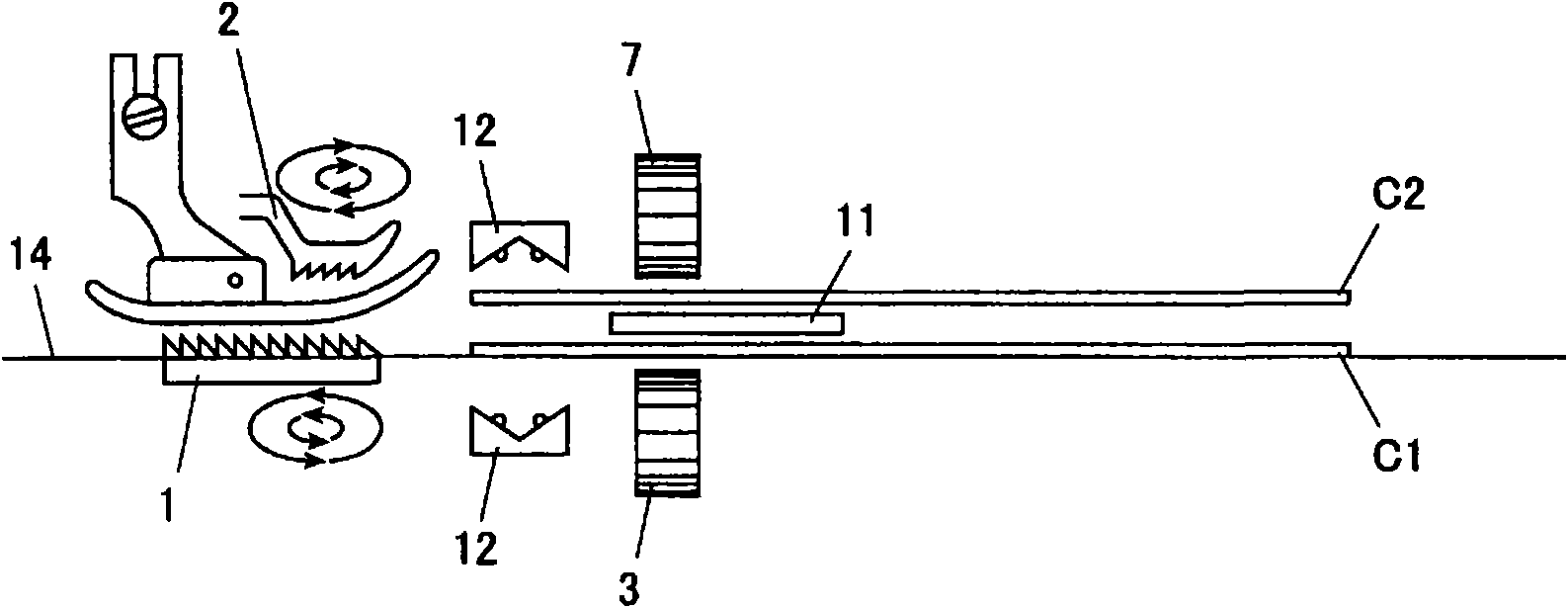

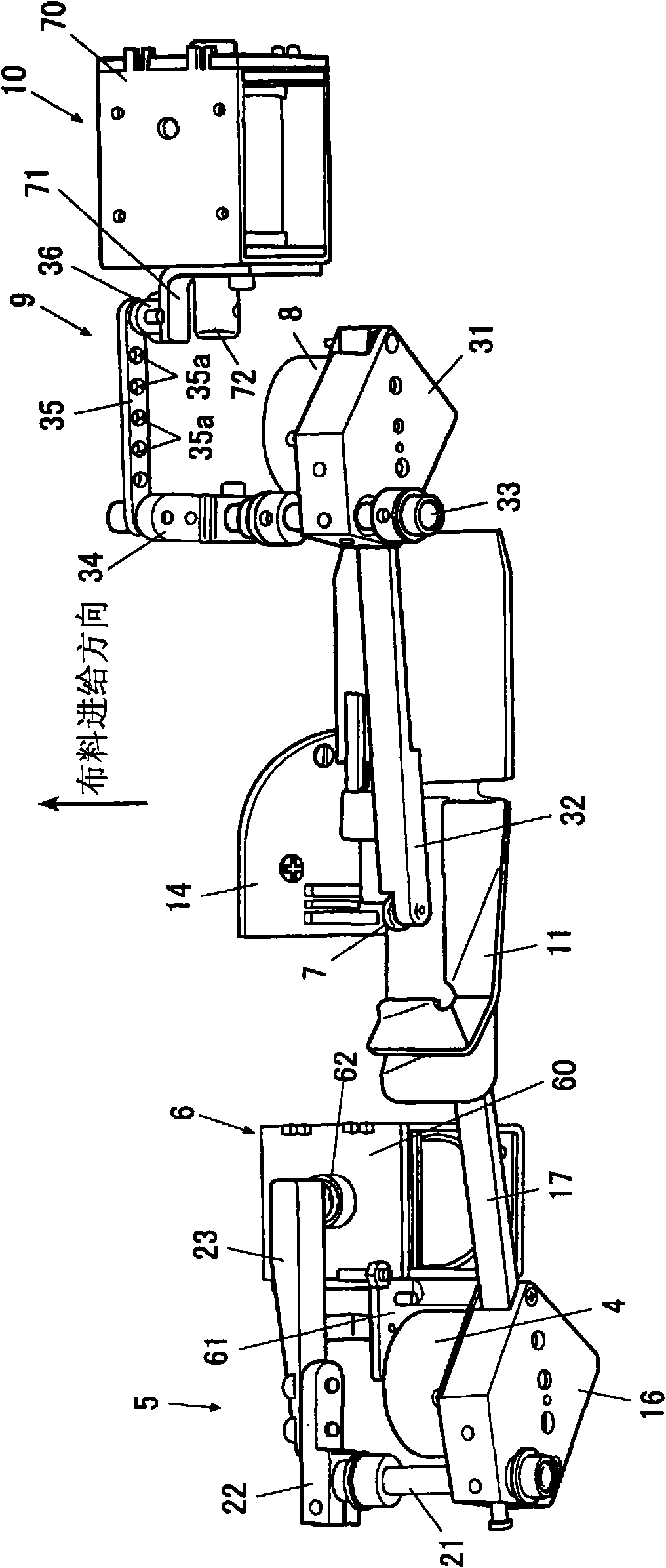

[0044] (Overall structure of the embodiment of the present invention)

[0045] exist figure 1 , 2Among them, the up and down feed sewing machine 100 has: feed gear 1, feed foot 2, lower side roller 3, lower side pulse motor 4, lower side connecting mechanism 5, lower side solenoid 6, upper side roller 7, upper side Pulse motor 8 , upper coupling mechanism 9 , upper solenoid 10 , separation plate 11 , cloth sensor 12 , and control device 13 .

[0046] Among them, the lower roller 3, the lower pulse motor 4, the lower connecting mechanism 5, the lower solenoid 6, the upper roller 7, the upper pulse motor 8, the upper connecting mechanism 9, the upper solenoid 10, The separation plate 11 and the cloth sensor 12 constitute an end adjustment mechanism, which moves and adjusts the positions of the ends of the two pieces of cloth C1 and C1 along the seam in a direction perpendicular to the feeding direction of the feed tooth 1 .

[0047] (feed tooth)

[0048] exist figure 2 Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com