Modified polyester/cotton blended fabric and dyeing method thereof

A technology for modifying polyester and blended fabrics, applied in dyeing, liquid/gas/vapor textile processing, textiles and papermaking, etc., can solve the problem of polyester fiber with large modulus, lower product grade, easy to pilling, etc. problems, to achieve the effect of high tensile strength, high tensile elongation at break, and high dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] 1. Fabric

[0134] The fabric is a modified polyester / cotton 30 / 70 blended fabric with a fabric weight of 185g / m 2 , plain weave structure.

[0135] The structural formula of the modified polyester has the following structural units:

[0136]

[0137] where 101 2 <70.

[0138] 2. Dyeing

[0139] 1) carrying out pretreatment to fabric, described pretreatment is alkali+hydrogen peroxide bleaching process commonly used in this field;

[0140] 2) Dip the pretreated fabric into the dyeing bath at 25°C, where the dyeing bath contains 0.8% of Disperse Blue E-4R, 1g / L of glacial acetic acid, and 0.3g / L of leveling agent;

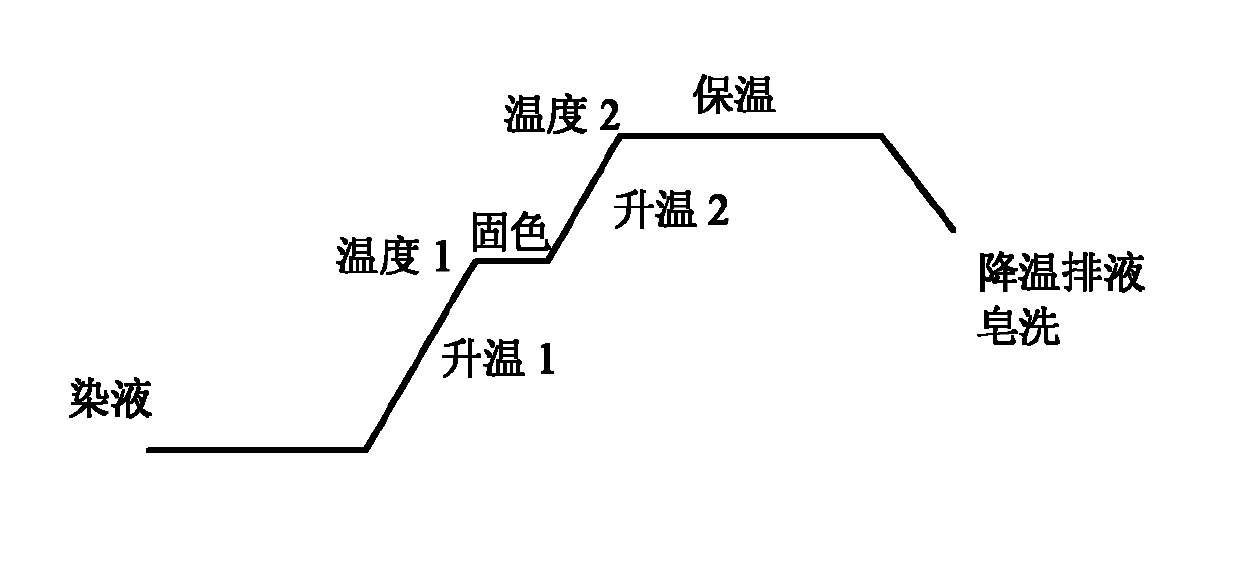

[0141] 3) Then raise the temperature at a rate of 2°C / min until the temperature of the dye bath is 98°C, keep it warm for 20 minutes, drain, and wash with water;

[0142] 4) Add active navy blue L-3G 1.2% (o.w.f), sodium chloride 15g / L, soda ash 5g / L, chelating dispersant 0.5g / L to the dyeing bath, and then heat up at a speed of 0.5°C / min until the dy...

Embodiment 2

[0146] 1. Fabric

[0147] The fabric is a modified polyester / cotton 70 / 30 blended knitted fabric with a fabric weight of 210g / m 2 , the organizational structure is ribbed.

[0148] The structural formula of the modified polyester has the following structural units:

[0149]

[0150] where 101 2 3 <5.

[0151] 2. Dyeing

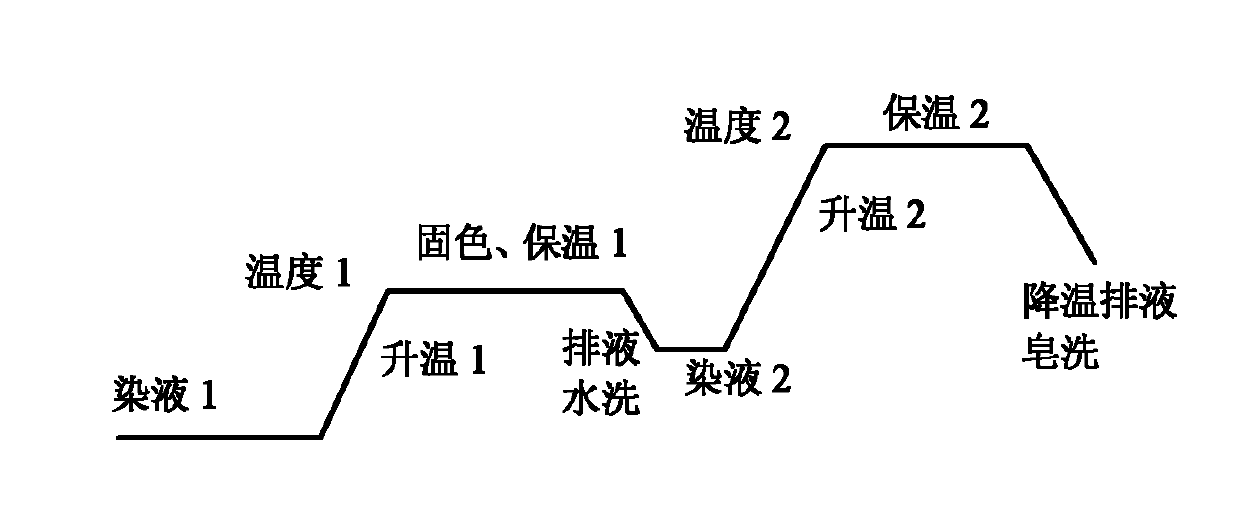

[0152] 1) Dye the fabric by immersing it in a dyeing bath at 20°C, wherein the dyeing bath contains 1.0% reactive red FN-2BL, 10g / L sodium sulfate, 4g / L soda ash, and 1g / L chelating dispersant;

[0153] 2) Then raise the temperature at a rate of 1.0°C / min until the temperature of the dye bath is 60°C, add 6g / L of soda ash, keep it warm for 30 minutes, drain and wash with water;

[0154] 3) Add Disperse Yellow 4G 1.5% (o.w.f) to the dye bath, adjust the pH value of the dye bath to 5 with glacial acetic acid and sodium acetate, then raise the temperature at a rate of 2 °C / min until the dye bath temperature is 100 °C, and keep it warm for 20 minutes ;

...

Embodiment 3

[0158] 1. Fabric

[0159] The fabric is a modified polyester / cotton 10 / 90 blended knitted fabric with a weight of 220g / m 2 , mesh tissue.

[0160] The structural formula of the modified polyester has the following structural units:

[0161]

[0162]

[0163] where 101 2 3 4 <5.

[0164] 2. Dyeing

[0165] 1) Dye the fabric by immersing it in a dyeing bath at 20°C, wherein the dyeing bath contains 2.3% (o.w.f) of reactive black G, 20g / L of sodium chloride, 5g / L of sodium carbonate, and 1.5g / L of chelating dispersant;

[0166] 2) Then raise the temperature at a speed of 0.8°C / min until the temperature of the dyeing bath is 60°C, add 2g / L of color-fixing alkali, and run for 30min to fix the color;

[0167] 3) After fixing the color, directly add some glacial acetic acid and disperse black HL 0.5% to the dye bath, run for 10 minutes and raise the temperature at a speed of 1.5 °C / min until the dye bath temperature is 100 °C, and keep it warm for 30 minutes;

[0168] 4) Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap