Hopper bearing device of road surface paver

A technology of a support device and a paver, applied in the field of construction machinery, can solve the problems of increasing the bearing pressure of a hopper, frequent replacement cycles of rubber pads, and easy aging of rubber pads, avoiding impact deformation, facilitating promotion and use, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

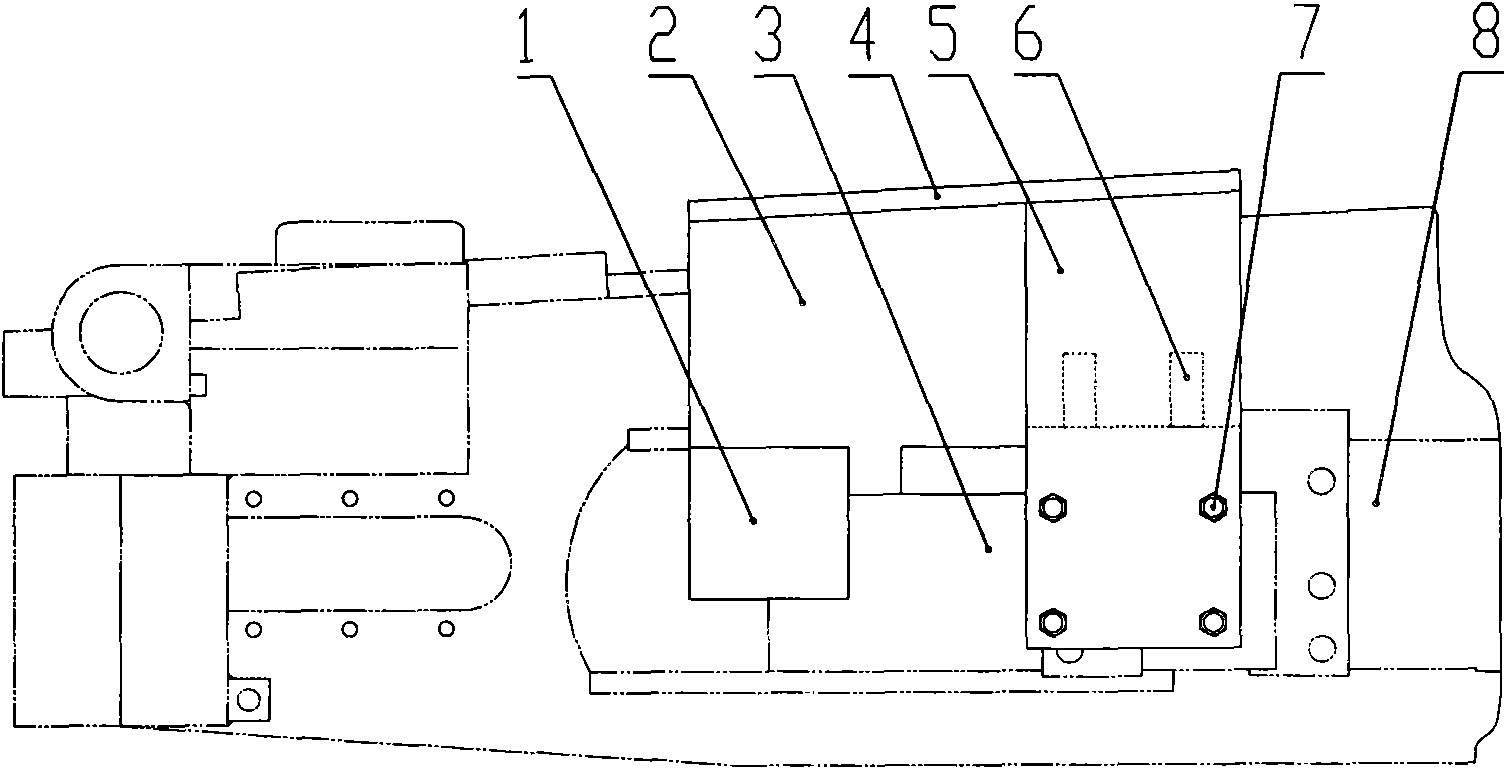

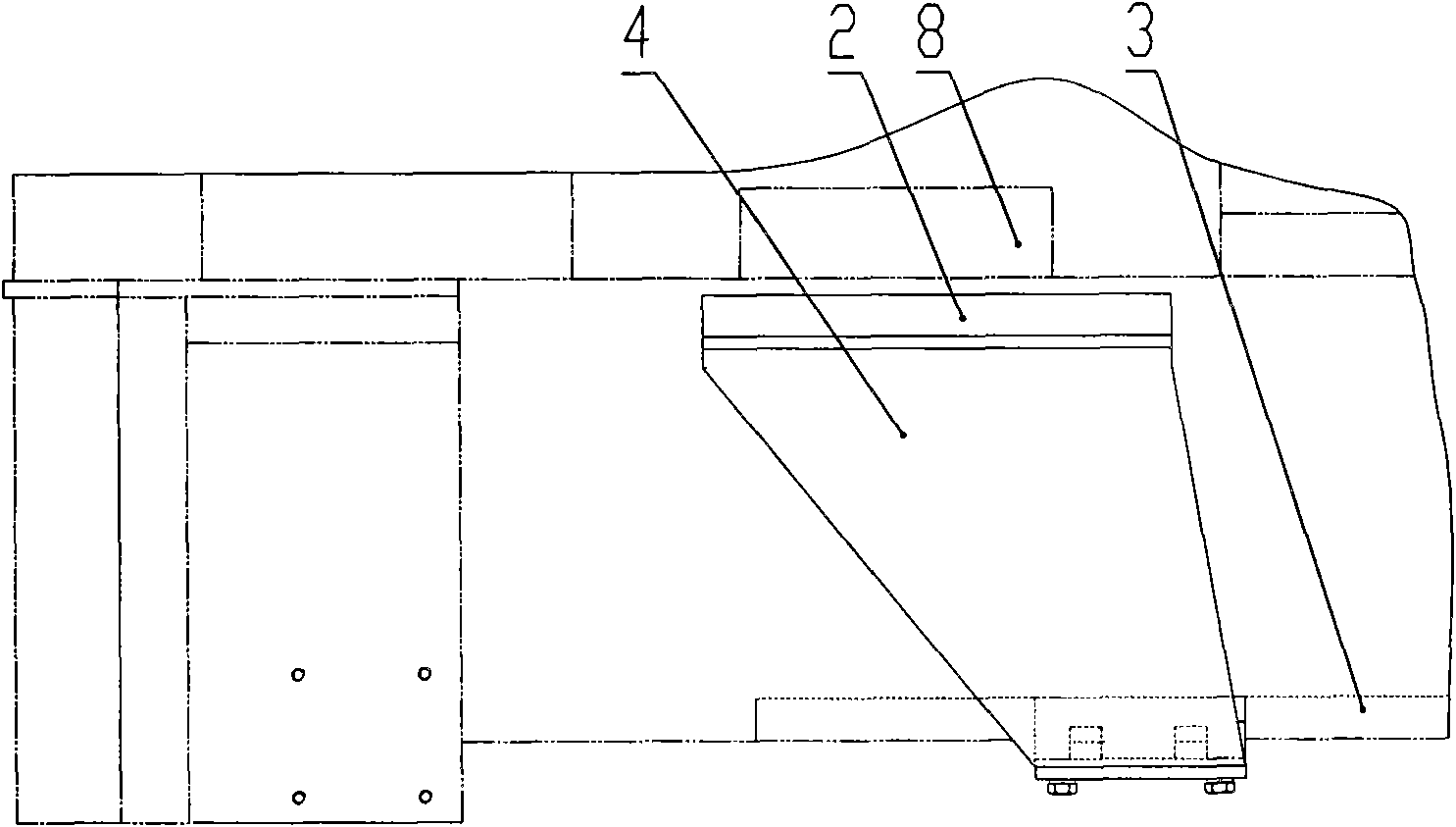

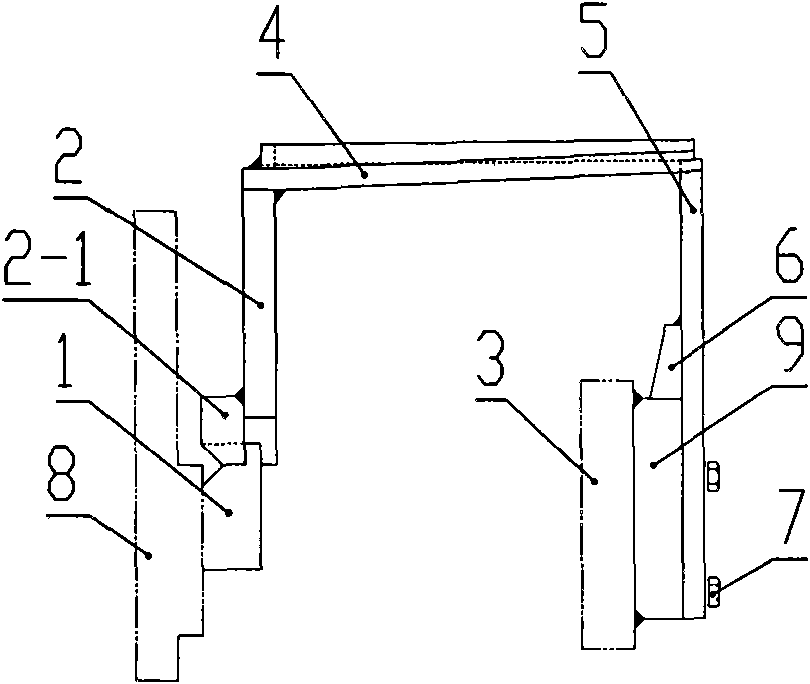

[0014] Such as figure 1 , 2 , Shown in 3: The road paver hopper support device consists of two sets of support frames that are mutually symmetrical, identical in shape and size, and are respectively installed at the lower part of the left and right hoppers of the paver. The support frame includes: hopper supporting plate 4, frame supporting plate 2, frame fixing plate 1, track supporting plate 5 and track fixing plate 9; When the machine hopper is fully opened, the bottom plate of the hopper is closely attached to the hopper support plate 4; the stress area of the hopper is increased, the bearing pressure per unit area of the hopper is reduced, the impact pressure of the hopper is relieved instantaneously, and the impact tension of the hopper cylinder is prevented from being overloaded. The frame fixing plate 1 is fixed on the outside of the frame beam 8, the upper end of the frame supporting plate 2 is connected with the hopper supporting plate 4, and the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com