Handrail assembly and stand combination

A handrail and frame technology, which is applied in the field of installation structure of handrail components of generator sets, can solve problems such as inconvenient operation, poor safety, scrapped cartons, etc., achieve good reliability and safety, improve convenience, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

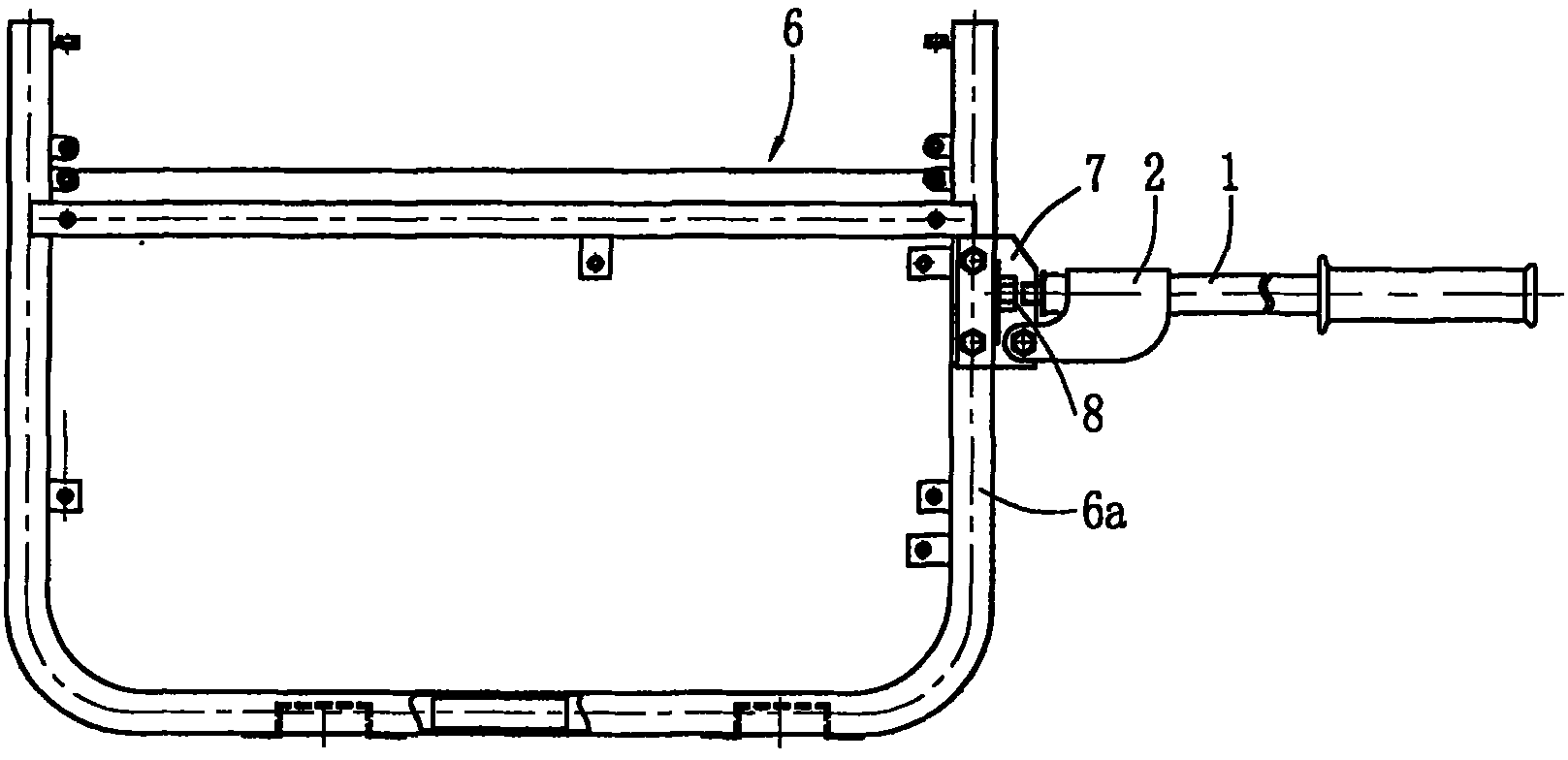

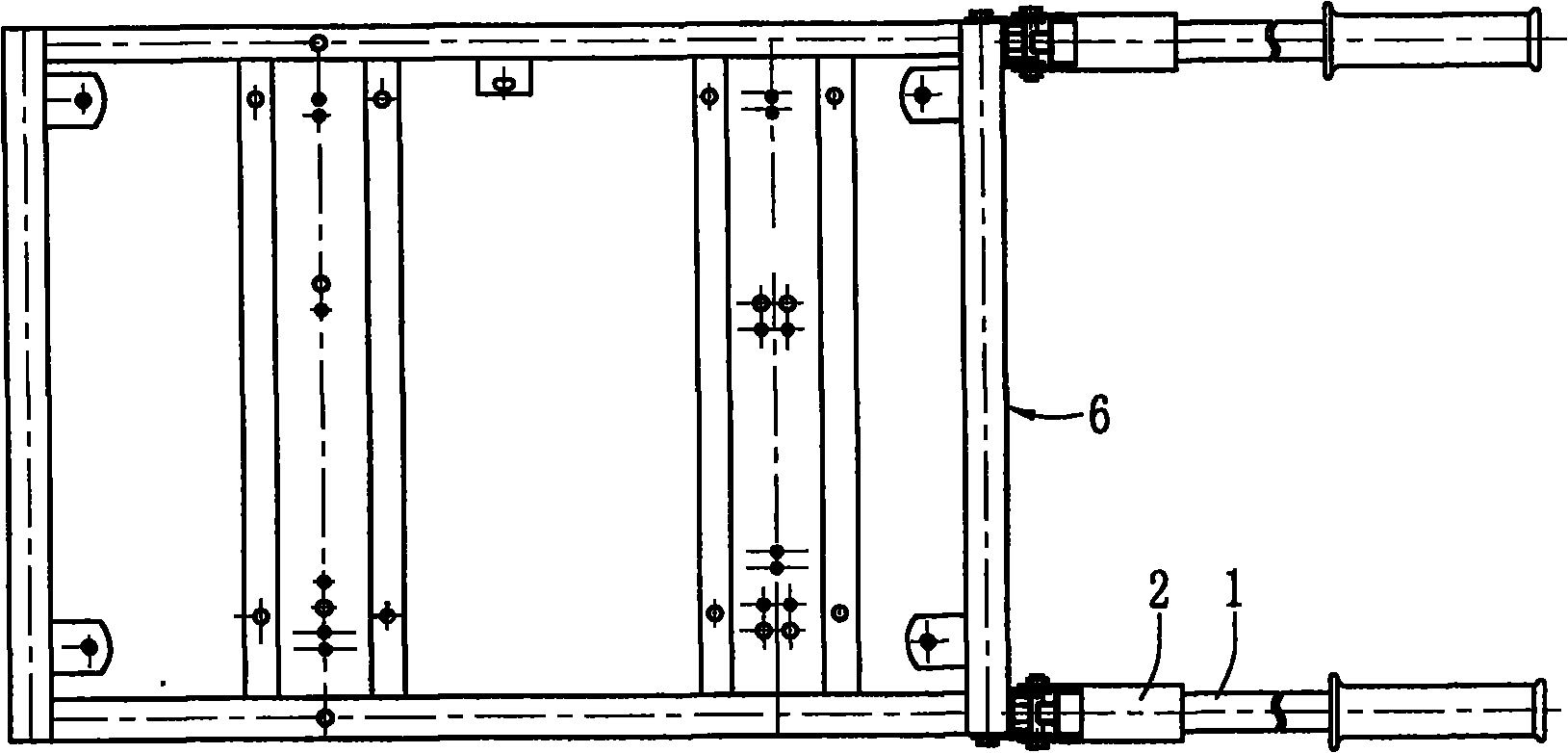

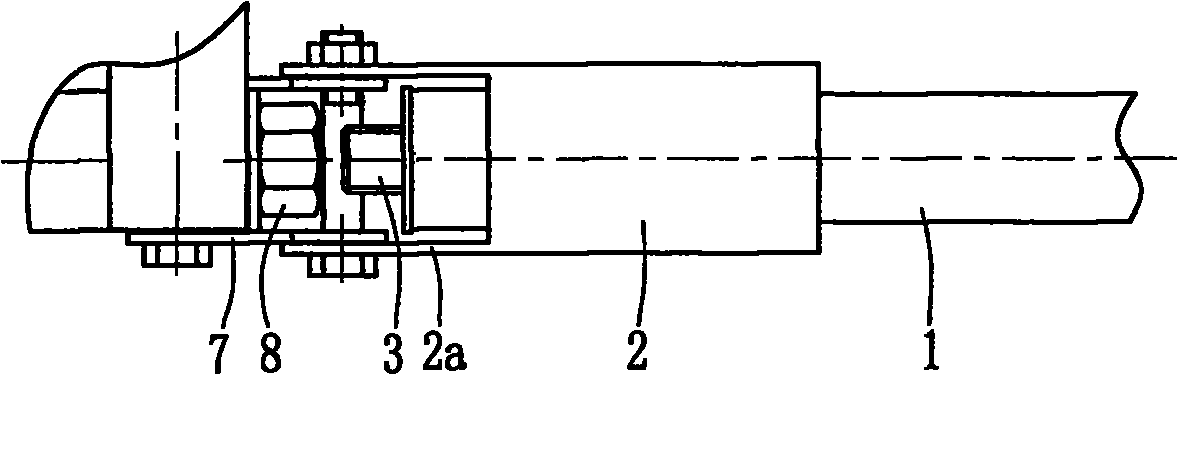

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0022] From Figure 1 to Figure 8 As can be seen, the present invention is made of handle 1, support 2, stud 3, bushing 4, rubber sleeve 5, frame 6, armrest seat 7 and nut 8. The handle 1 is a straight-through pipe structure, in the handle 1 such as Figure 4 The shown right end is sheathed with a rubber sleeve 5, and the left end of the handle 1 is provided with a stud 3. The stud 3 is a stepped cylindrical structure, and the axis of the stud 3 is on the same line as the axis of the handle 1 . The small cylindrical section of the stud 3 is processed with external threads, and the large cylindrical section of the stud 3 extends into the handle 1 and is fixed by welding with the handle 1. A ring of bosses 3 a are integrally formed at the end of the large cylindrical section of the stud 3 , and the bosses 3 a abut against the end surface of the handle 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com