Defrosting control system and control method of refrigerator

A control system and refrigerator technology, applied in the control/regulation system, defrosting, temperature control, etc., can solve the problems of refrigerator energy consumption and cooling waste, and achieve the effect of saving energy, reducing energy consumption, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

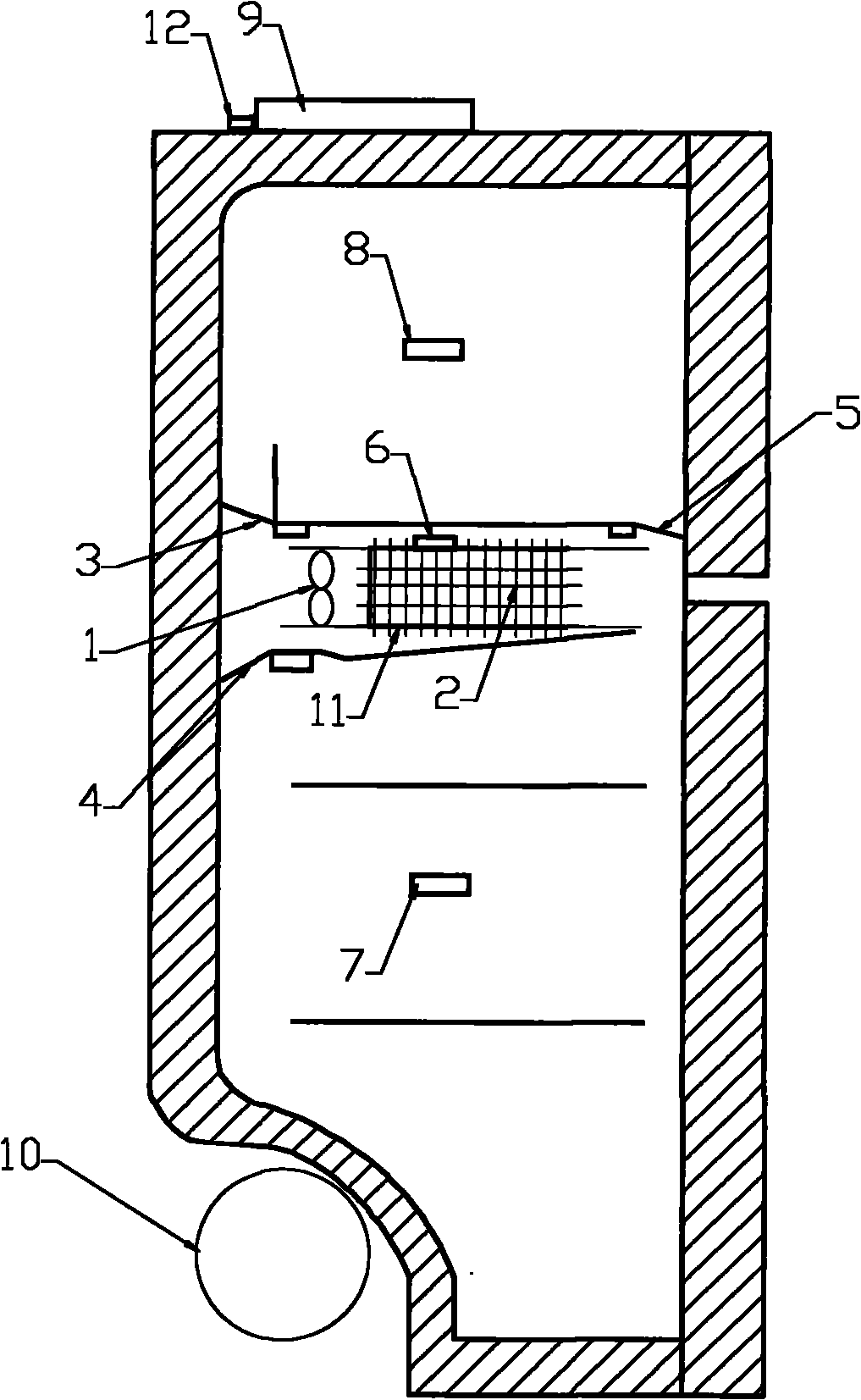

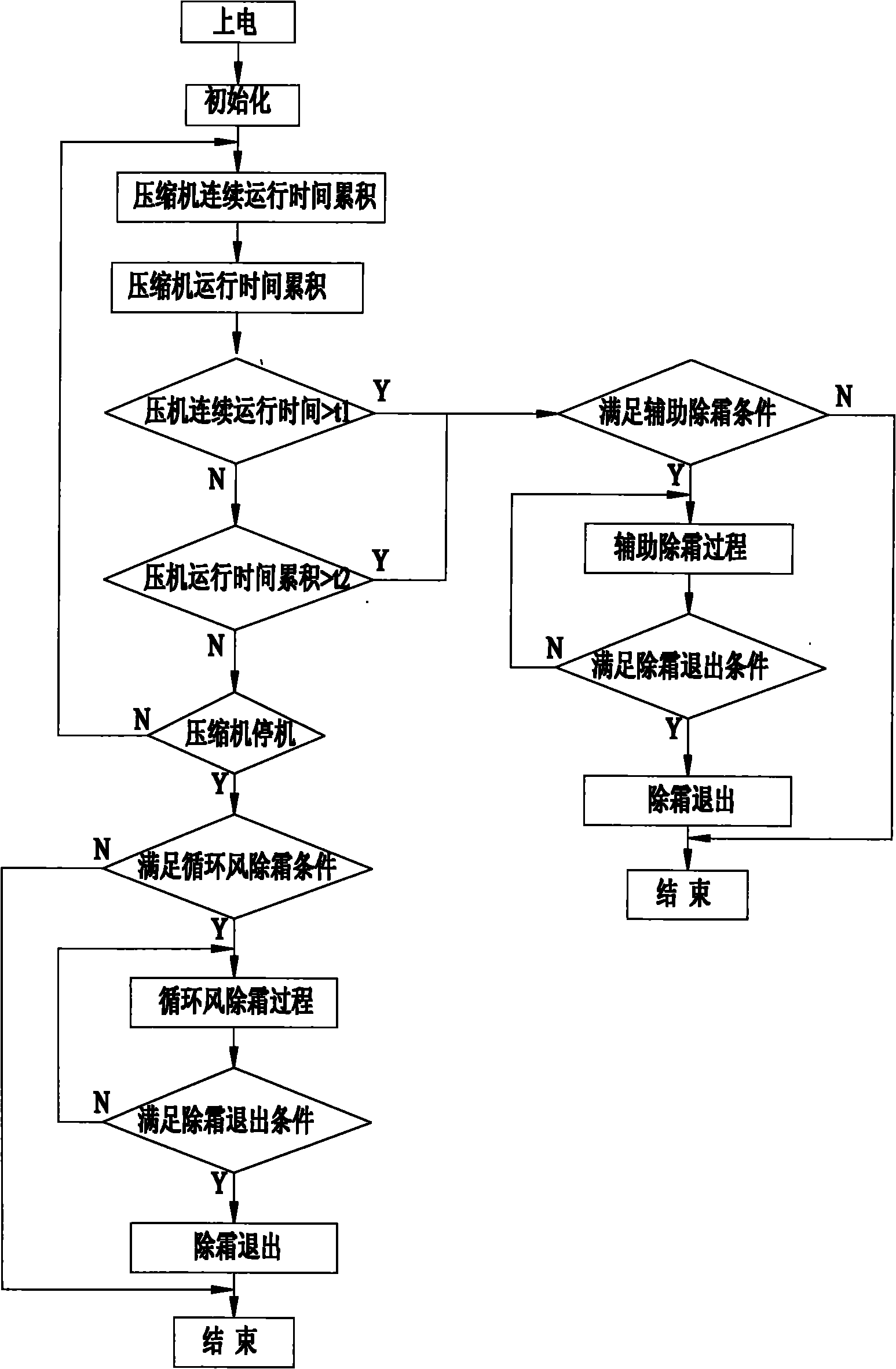

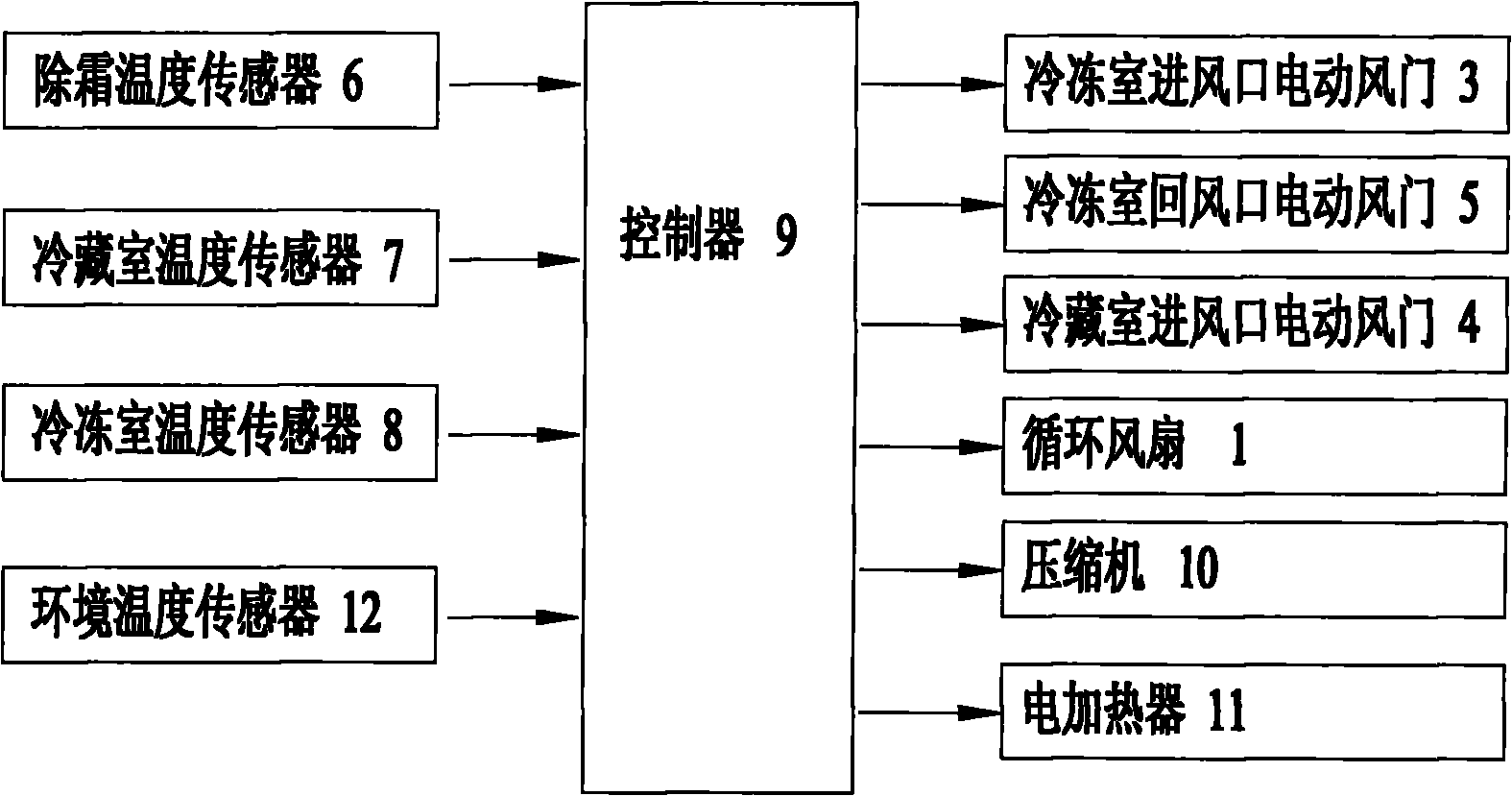

[0024] figure 1 , image 3 They are respectively a schematic diagram and a block diagram of the structure of the control system of the present invention, including a circulating fan 1, a controller 9, a defrosting temperature sensor 6 connected to the controller 9, a refrigerator temperature sensor 7, a freezer temperature sensor 8 and an ambient temperature sensor 12. The circulation fan 1 is installed on the side of the refrigerator evaporator 2, as shown in the figure behind the refrigerator evaporator 2. The air duct behind the circulation fan 1 is divided into the air inlet of the freezer and the air inlet of the refrigerator, and the air inlet of the freezer and the air inlet of the refrigerator. The electric damper 3 of the air inlet of the freezer and the electric damper 4 of the air inlet of the refrigerator are respectively installed at the air inlet of the refrigerator. Return air outlet electric damper 5. The control system of the present invention also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com