Port gantry crane low-noise lifting motor

An electric motor and gantry technology, applied in the field of electric motors, can solve problems such as high motor noise, reduce electromagnetic vibration and electromagnetic noise, meet the requirements of low noise and environmental protection, and reduce the effect of amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

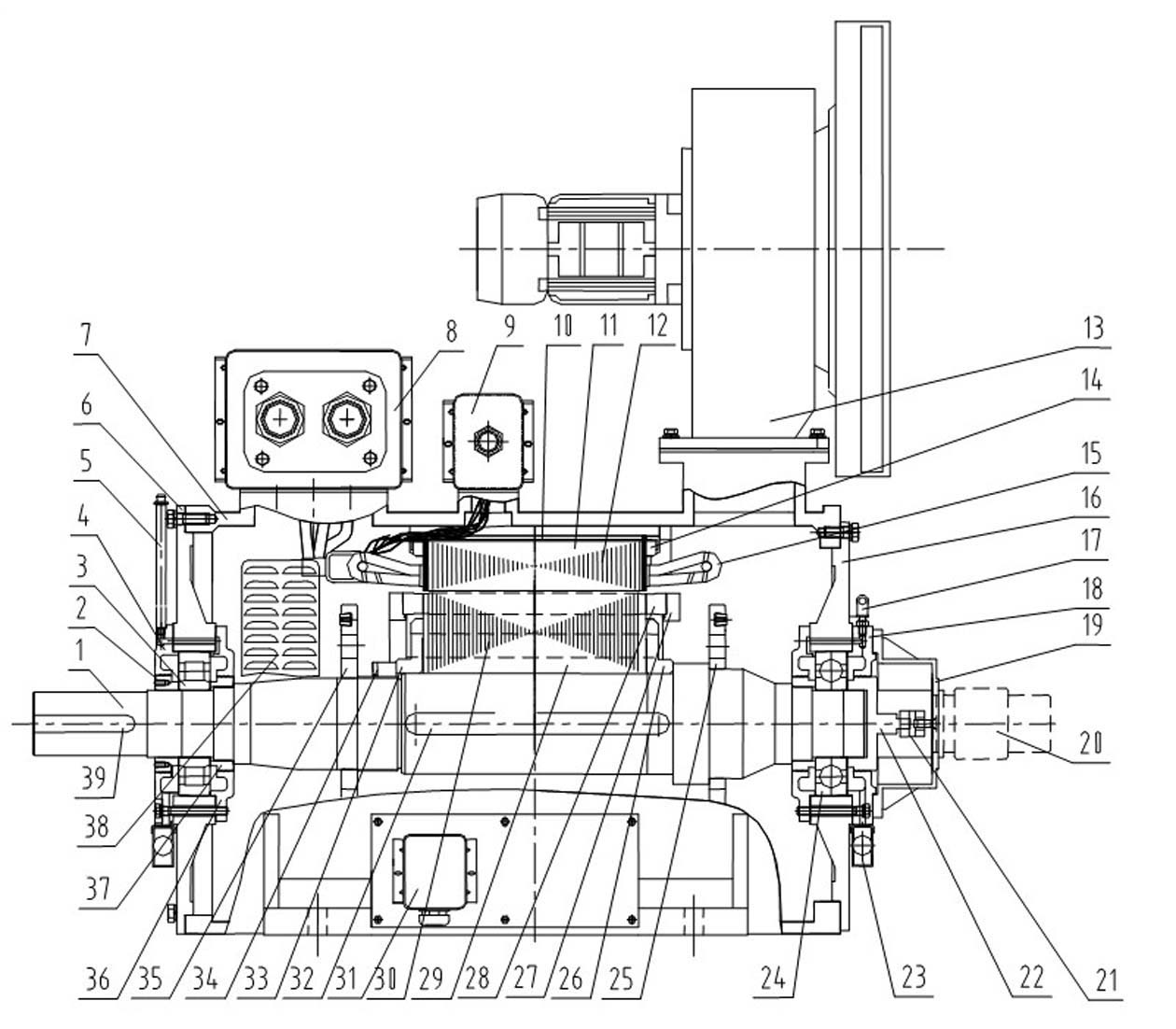

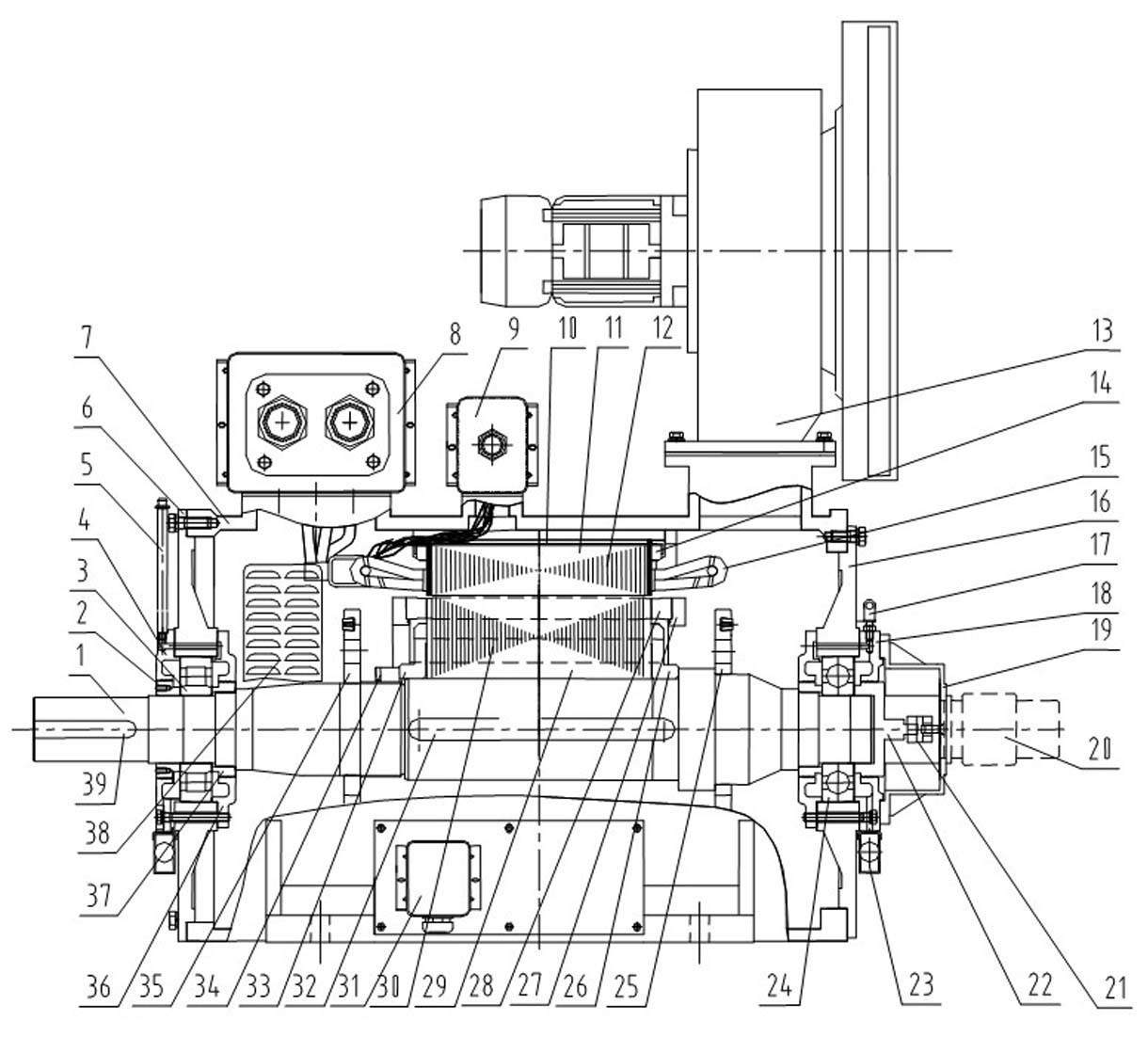

[0030] The low-noise hoisting motor of the port machine gantry crane includes a machine base 7 and a stator core 11; the stator core 11 is formed by laminating stator punching sheets, and a stator coil 15 is arranged inside the stator core 11, and the two ends of the machine base 7 are respectively fixed with front, Rear end cover 16, 6, front and rear end cover are supported with rotating shaft 1 through bearing, and rotor iron core 29 is arranged on rotating shaft 1, and rotor iron core 29 is formed by lamination of rotor punching sheet, and guide bar 28 is housed in the groove of rotor iron core 29, The two ends are welded with the end ring 27 into one squirrel cage; the number of punching slots in the stator is 54, and the number of punching slots in the rotor is 66; the stator coil uses formed windings, which are wound with a pitch of 7 and a winding short distance ratio β of 7 / 9.

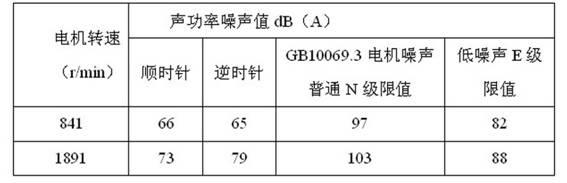

[0031] Furthermore, the electromagnetic design reduces the air gap magnetic density to belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com