Patents

Literature

72results about How to "Break the monopoly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Endoscope-based multispectral video navigation system and method

InactiveCN103300812ARealize acquisitionBreak the technological monopolyEndoscopesFluorescenceMolecular imaging

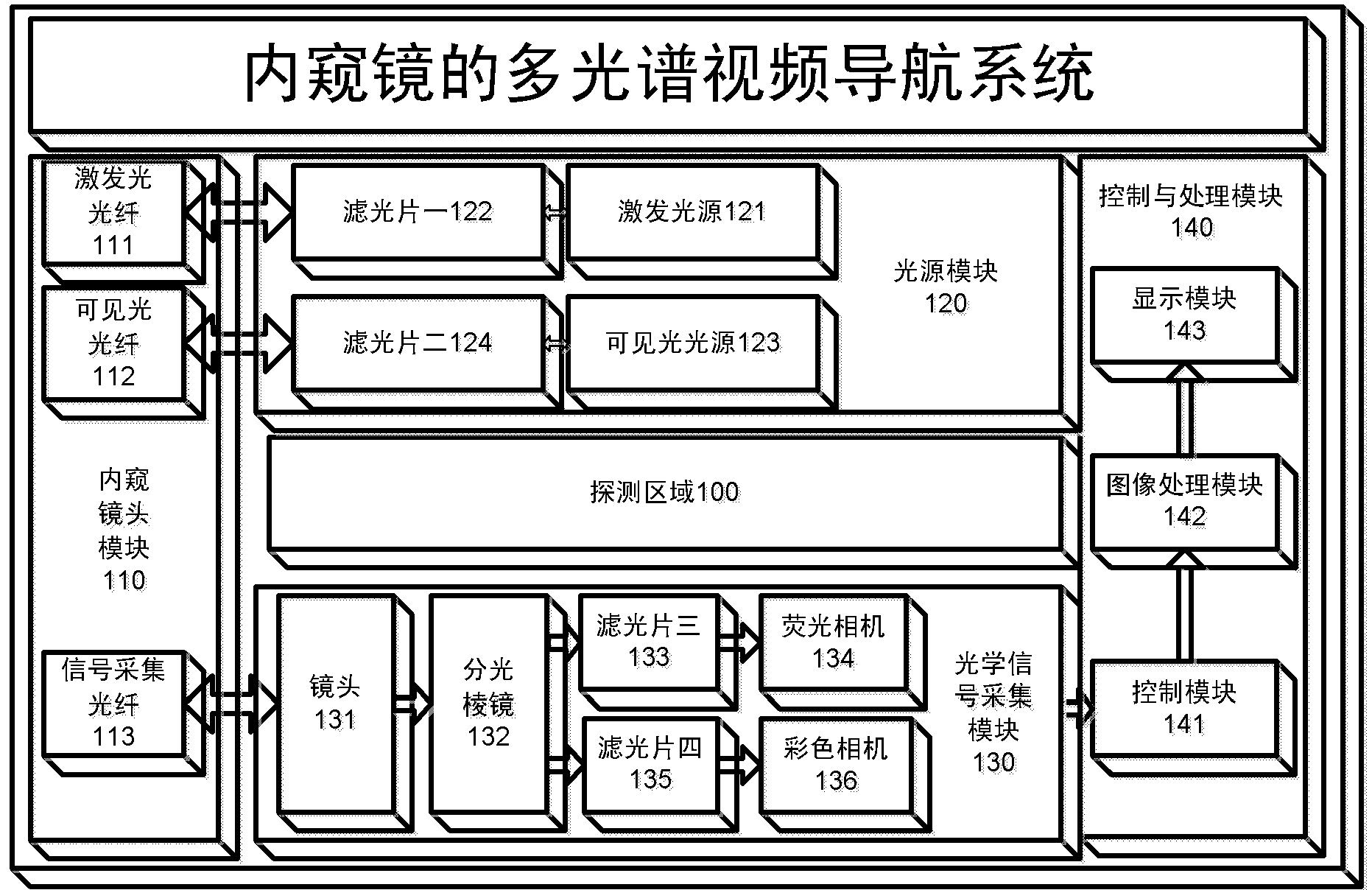

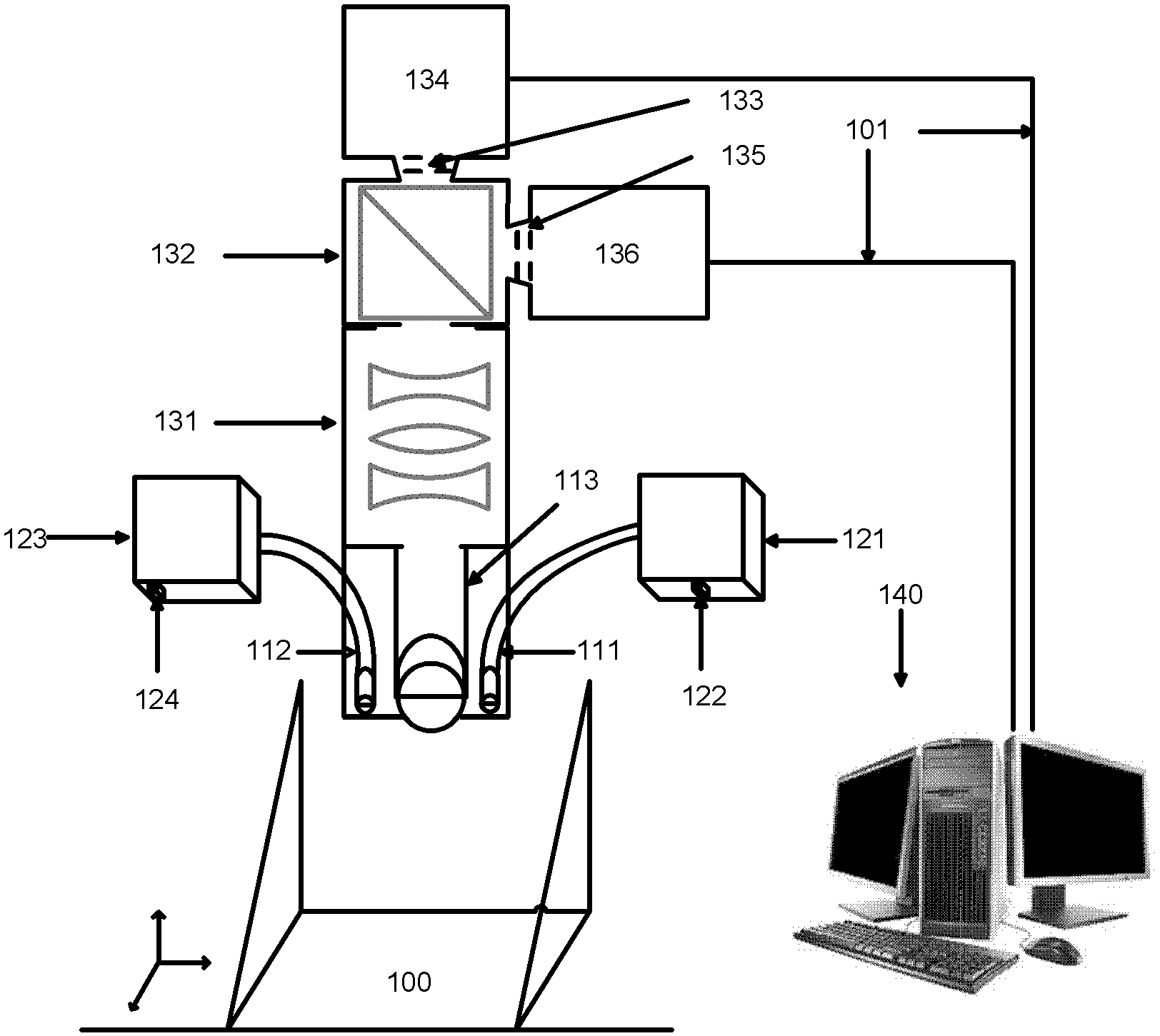

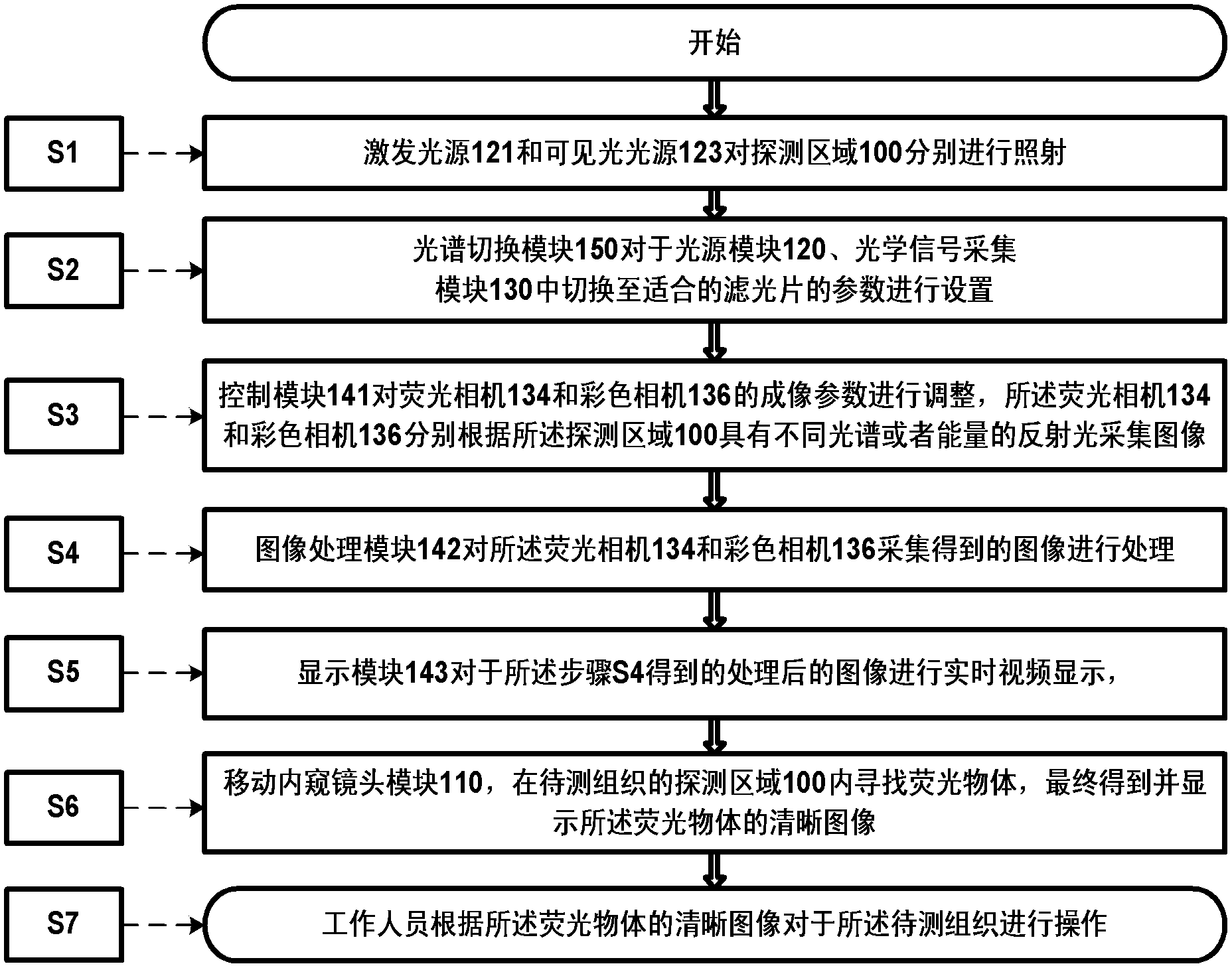

The invention discloses an endoscope-based multispectral video navigation system and method. The system comprises an endoscope head module used for internal inspection, a light source module used for providing near infrared and visible light sources, an optical signal acquisition module used for acquiring near infrared and visible light images, a multispectral conversion module used for imaging different spectrum segments, and a controlling and processing module used for controlling a camera and processing the acquired images to achieve video navigation. The invention also discloses a method utilizing the system to achieve multispectral video navigation. By adopting the system and the method, the problem that at present, most endoscope fluorescent products can only see fluorescent images or visible light images but not multispectral images is solved, technical monopoly of foreign companies in China is broken through, the imaging research threshold of the multispectral endoscope is lowered, the selection space of optical molecular imaging probes is expanded, and the optical molecular imaging research and application ranges are extended.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

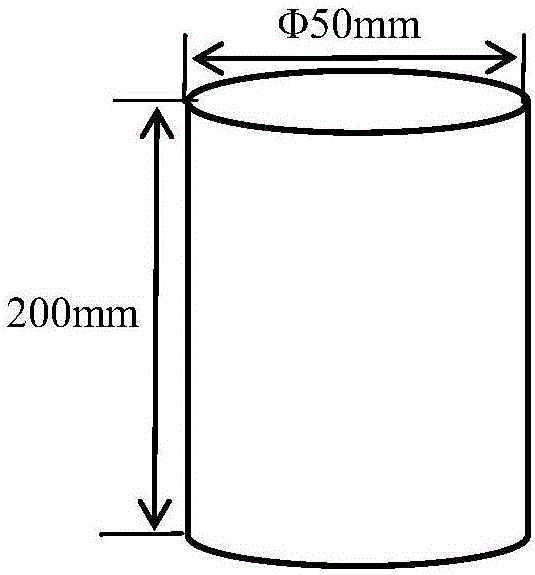

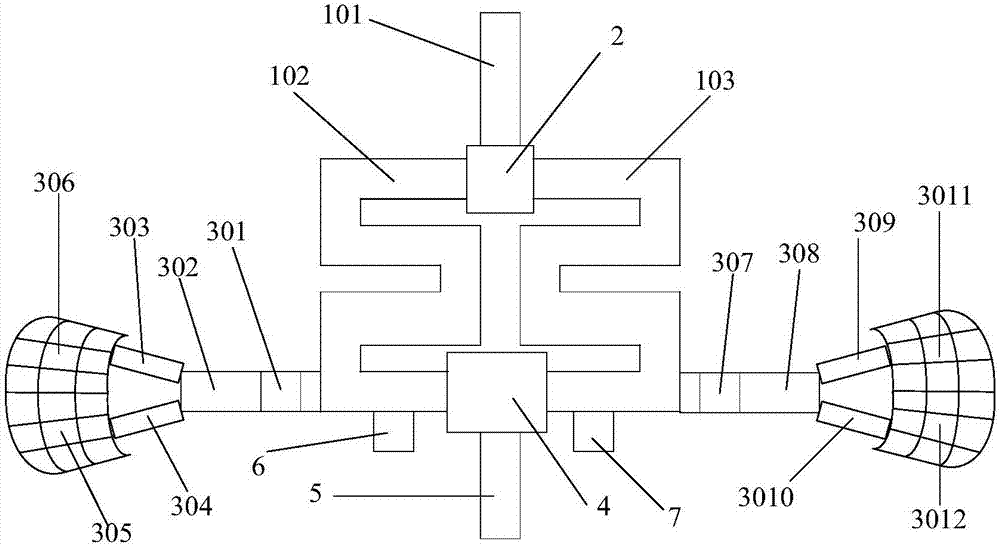

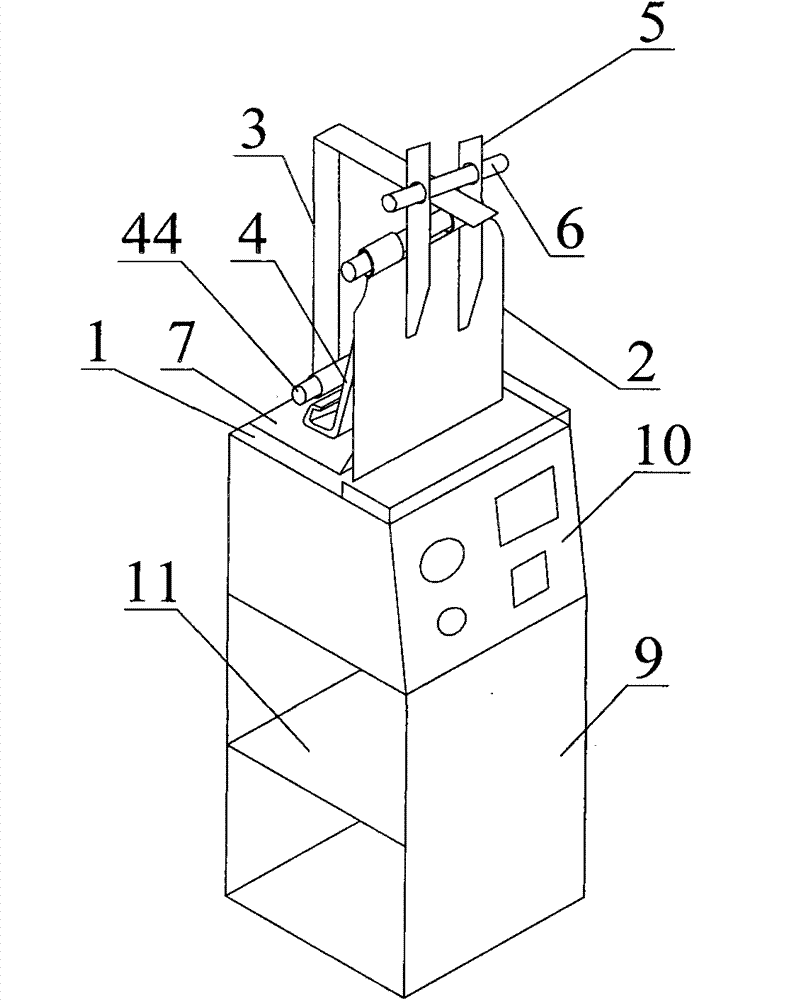

Alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing

InactiveCN106424748AWith mechanical controlWith automatic controlAdditive manufacturing apparatusTransportation and packagingAutomatic controlCollection system

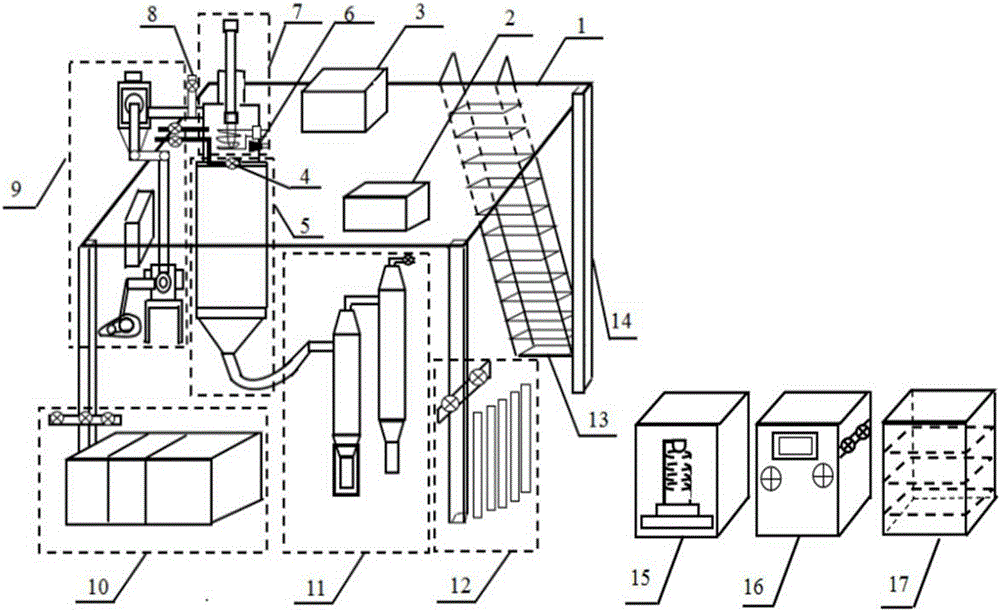

The invention relates to a high-performance alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing. The device comprises a vacuum acquirement and inflation system, an induction smelting system, an atomization powder preparation system, a power collection system and a power system. The preparation method includes that: (1) the induction smelting system selects a non-crucible induction system or a crucible induction system; (2) alloy bars are fixed on a continuous feeder, or nickel-based / cobalt-based alloy bars are put in a smelting chamber; (3) the smelting chamber, an atomizing chamber and a power collection device are vacuumized prior to be fed with inert gas; (4) induction smelting is started, when alloy reaches preset temperature, alloy droplets are enabled to enter the atomization powder preparation system, and nozzles are started to perform atomization powder preparation; alloyed power prepared in the atomization chamber is collected through the powder collection device. The device can realize mechanical control, automatic control and real-time monitoring; the prepared alloy powder is high in yield, uniform in particle size distribution, good in degree of sphericity, uniform in chemical component, good in mobility, low in oxygen content and low in hollow sphere rate.

Owner:NORTHEASTERN UNIV

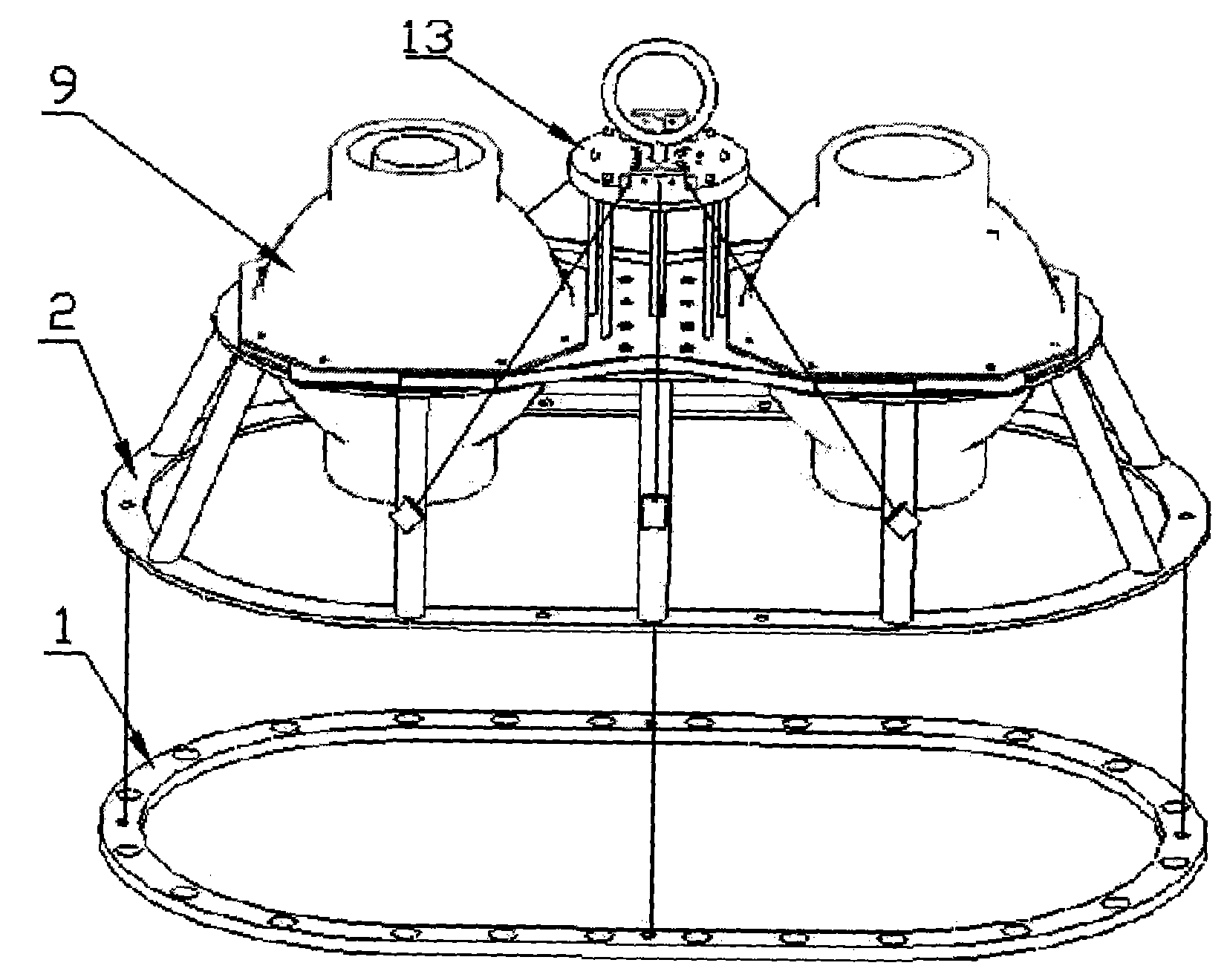

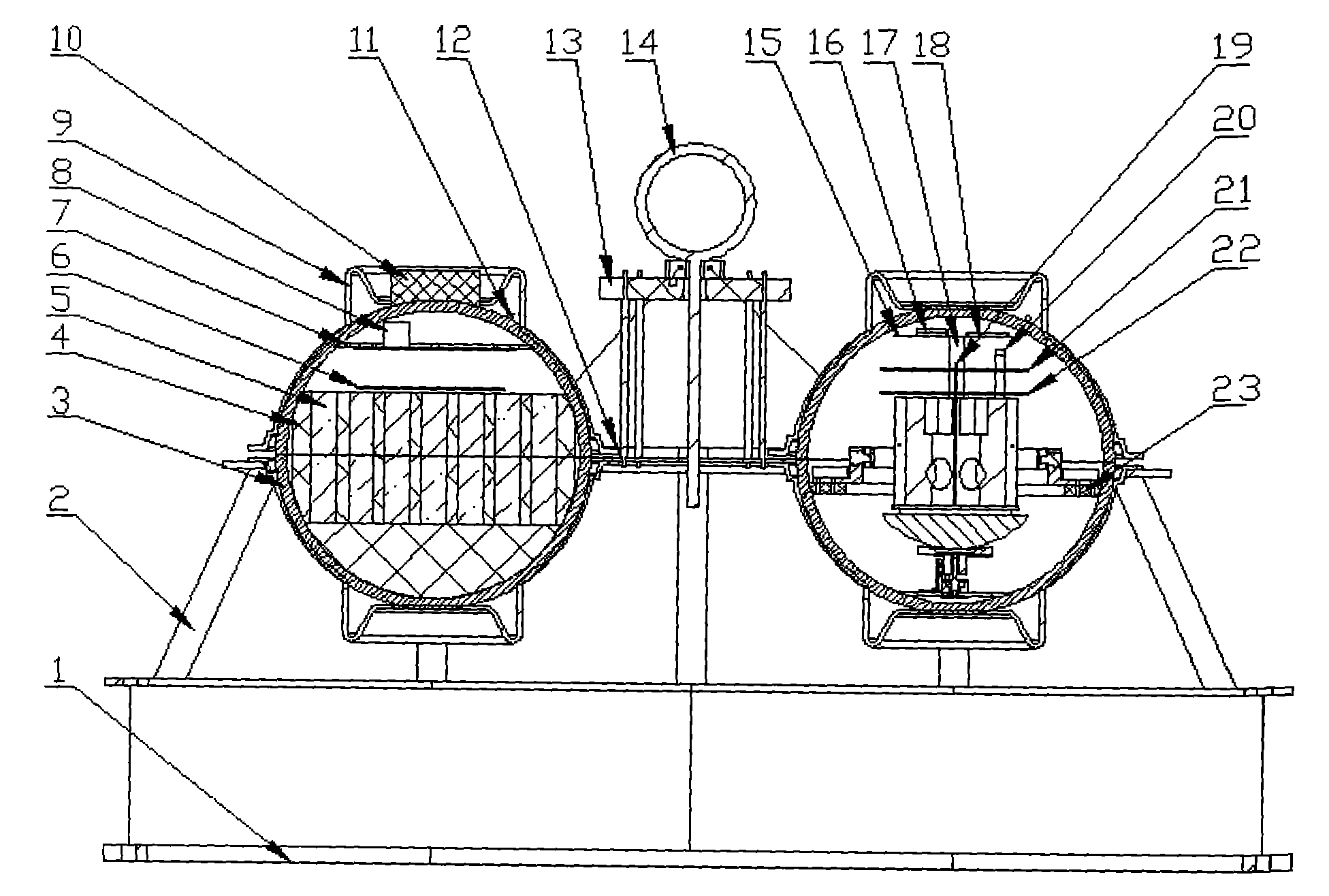

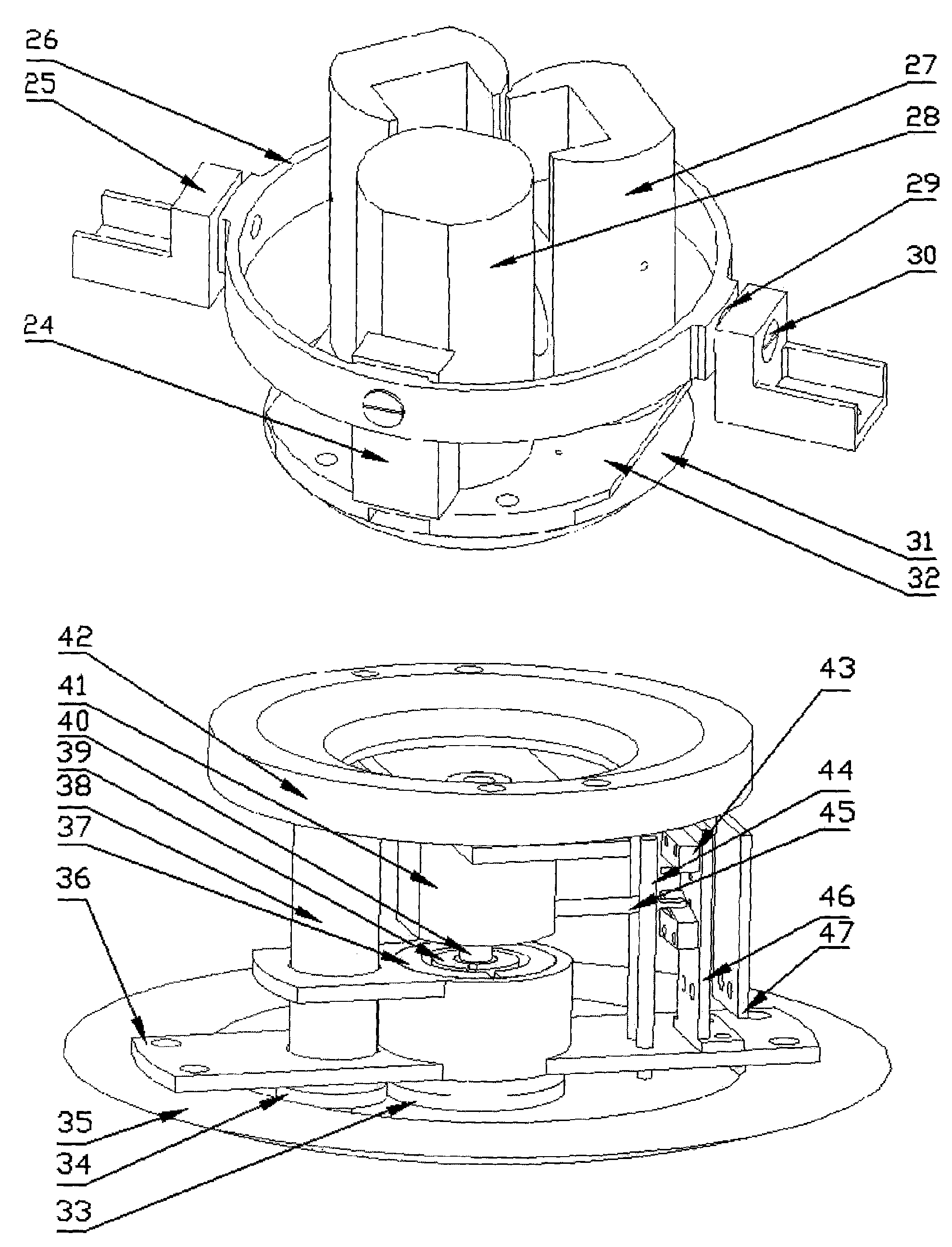

Broadband ocean bottom seismograph

InactiveCN101672927AExtended working hoursWork reliablySeismic signal receiversSeismology for water-covered areasData acquisitionEngineering

The invention discloses a broadband ocean bottom seismograph comprising two protecting shells and a connecting plate, wherein the two protecting shells are respectively fixed on both ends of the connecting plate; a sealed instrument storehouse ball and a sealed battery storehouse ball are respectively installed in the two protecting shells; a battery and an acoustic communication circuit are installed in the battery storehouse ball; two sealed storehouse balls are electrically connected by a cable; a gimbal for keeping the seismograph in a level state is arranged in the instrument storehouse ball and provided with a data collector and a seismograph; an electro erosion releasing mechanism for releasing a coupling frame is fixed on the connecting plate; the coupling frame for supplying downforces for the seismograph is positioned below the connecting plate and connected with the electro erosion releasing mechanism by wire ropes; and a weighting frame is connected below the coupling frame by an iron chain. The broadband ocean bottom seismograph can be used in deep ocean, and the observed broadband range is 40 s to 40 Hz; and the broadband ocean bottom seismograph is suitable not onlyfor viewing the ocean bottom natural earthquake, but also for viewing ocean bottom manmade earthquake source.

Owner:北京港震科技股份有限公司

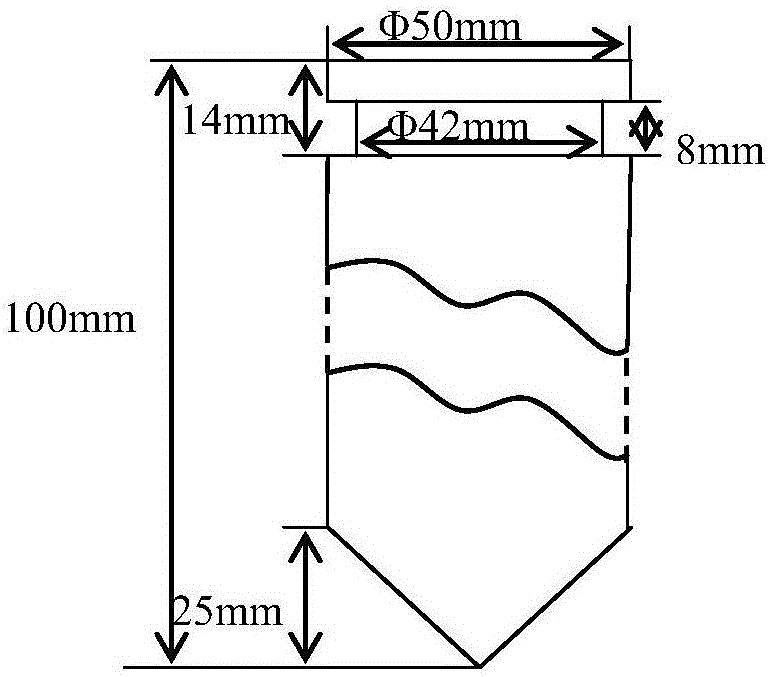

Method of preparing medical high-precision titanium and titanium alloy rod bar

InactiveCN101157172ARealize localizationLess investmentHeat treatment process controlMetallurgyEconomic benefits

The invention relates to medical high precision titanium and the manufacture method of a titanium alloy rod with a diameter tolerance level between h9 to h8 and the length between 3 m to 3.5 m without any clearance after being arranged on operating platform. The main steps of the manufacture method comprises blank preparation, cogging and forging, distorting and processing, heat treatment, finishing operation, examination, and final product packaging. The invention greatly decreases the equipment investment, realizes the purposes that the localization and exportation of the medical high precision titanium rod can be utilized rapidly, the monopoly situation of the products in the China market by foreign countries can be broken, the international competition can be participated, the stronger market competence can be formed, and the good economic benefit can be created.

Owner:宝鸡市英耐特医用钛有限公司

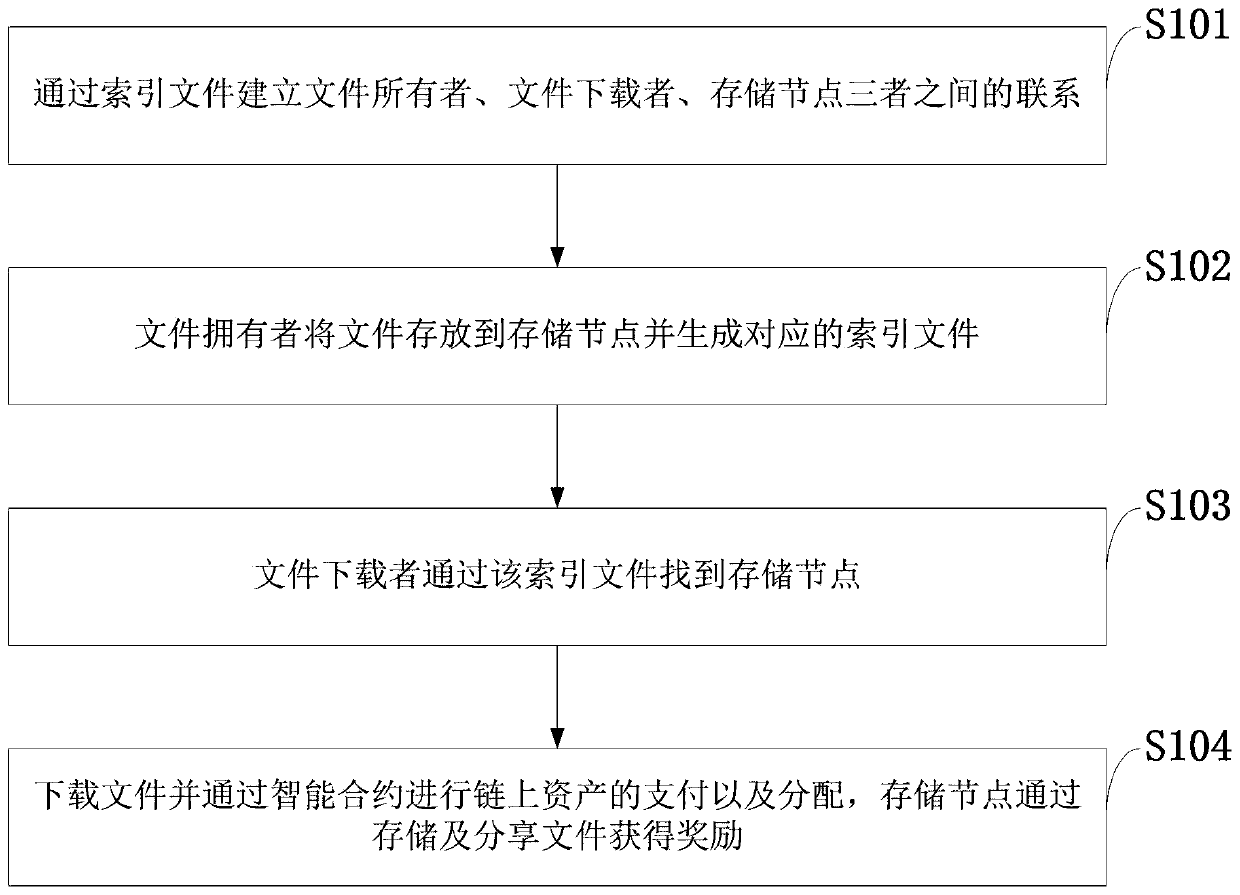

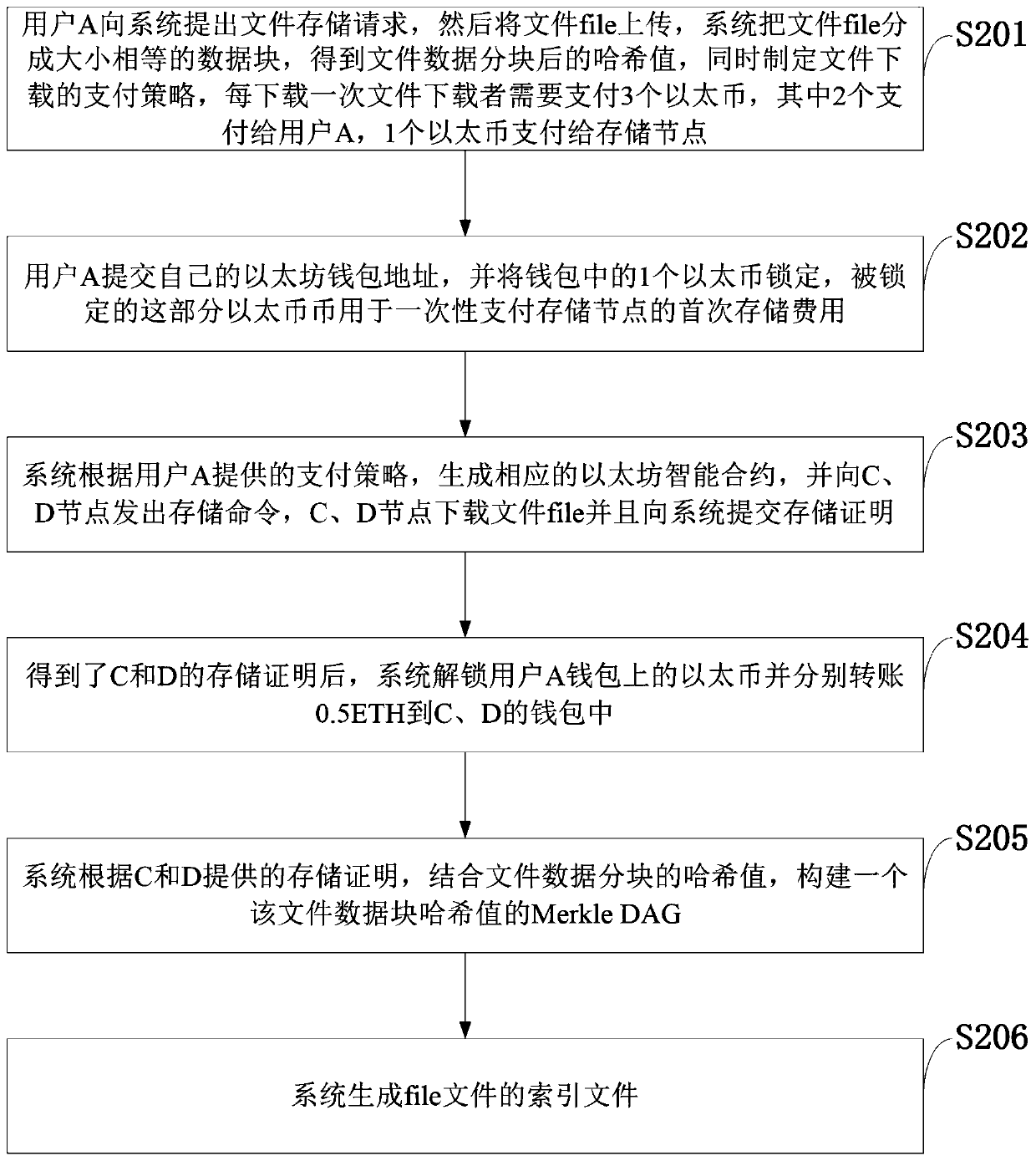

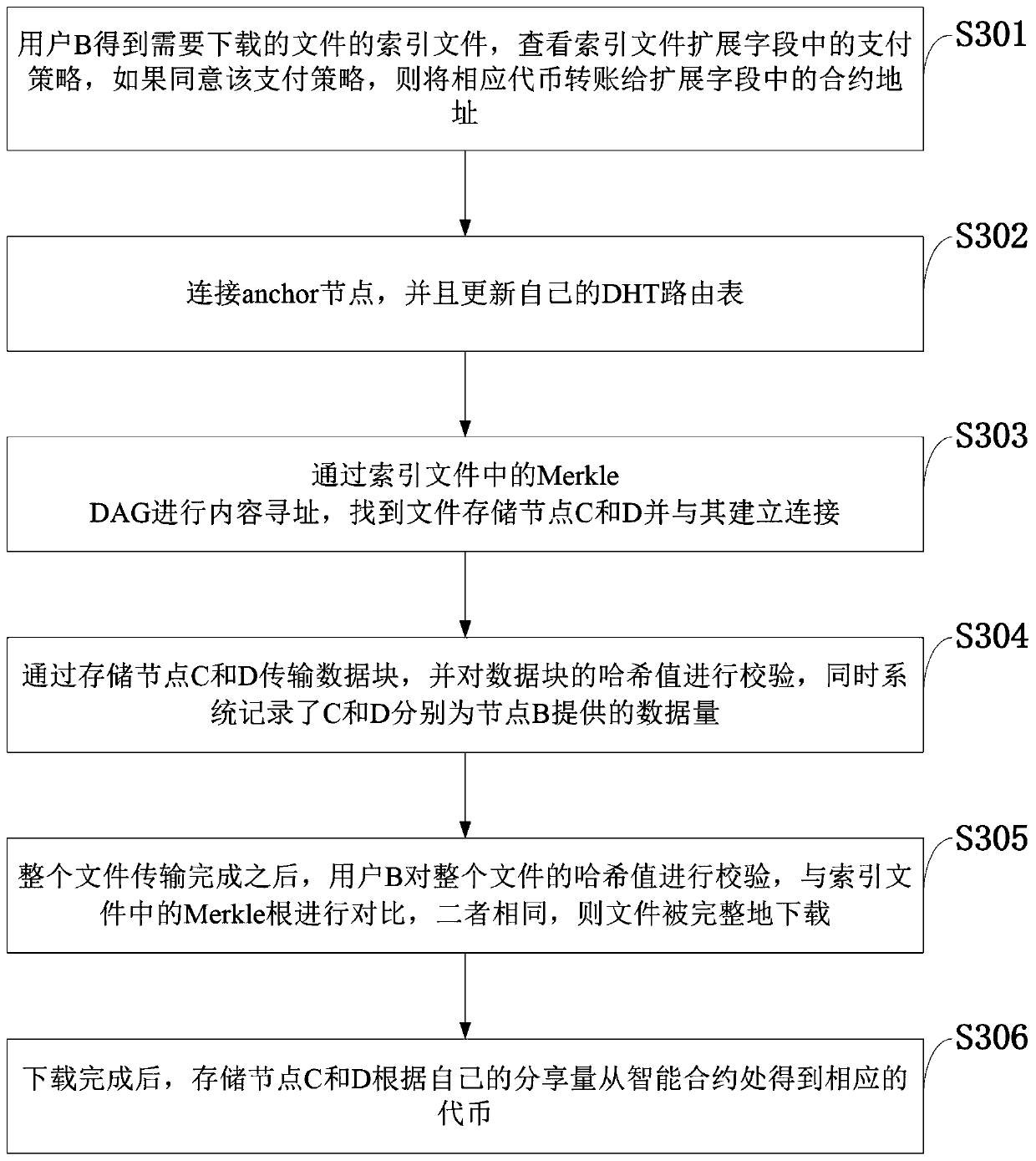

Distributed file indexing system and method based on block chain and cloud storage server

ActiveCN110399338AIncrease redundancyImprove securityFile access structuresFile metadata searchingResource utilizationSmart contract

The invention belongs to the technical field of file distributed storage and distributed indexing. The invention discloses a distributed file indexing system and method based on a block chain and a cloud storage server. A relationship among the file owner, the file downloader and the storage node is established through the index file; and a file owner stores a file in a storage node and generatesa corresponding index file, a file downloader finds the storage node through the index file, downloads the file and pays and distributes assets on a chain through an intelligent contract, and the storage node obtains awards through file storage and sharing. According to the invention, a centralized inquiry server can be omitted, the file sharing fairness is guaranteed through the intelligent contract, and the resource utilization rate is greatly increased; and meanwhile, the block chain network and the storage network are decoupled, the block chain network does not directly store data, only MerkleDAG containing the file hash value is stored, mutual cooperation is achieved, and the practicability is improved.

Owner:XIDIAN UNIV +1

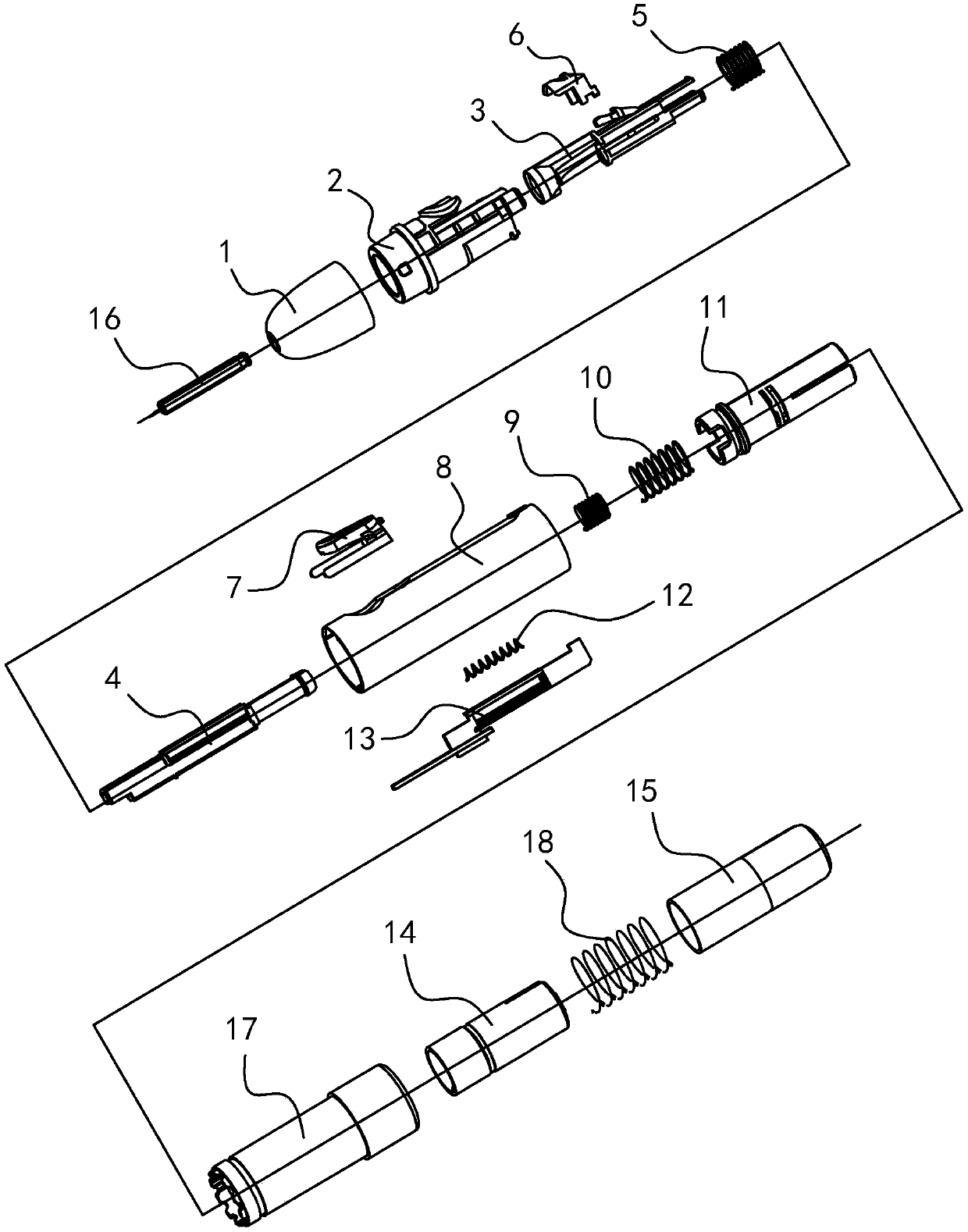

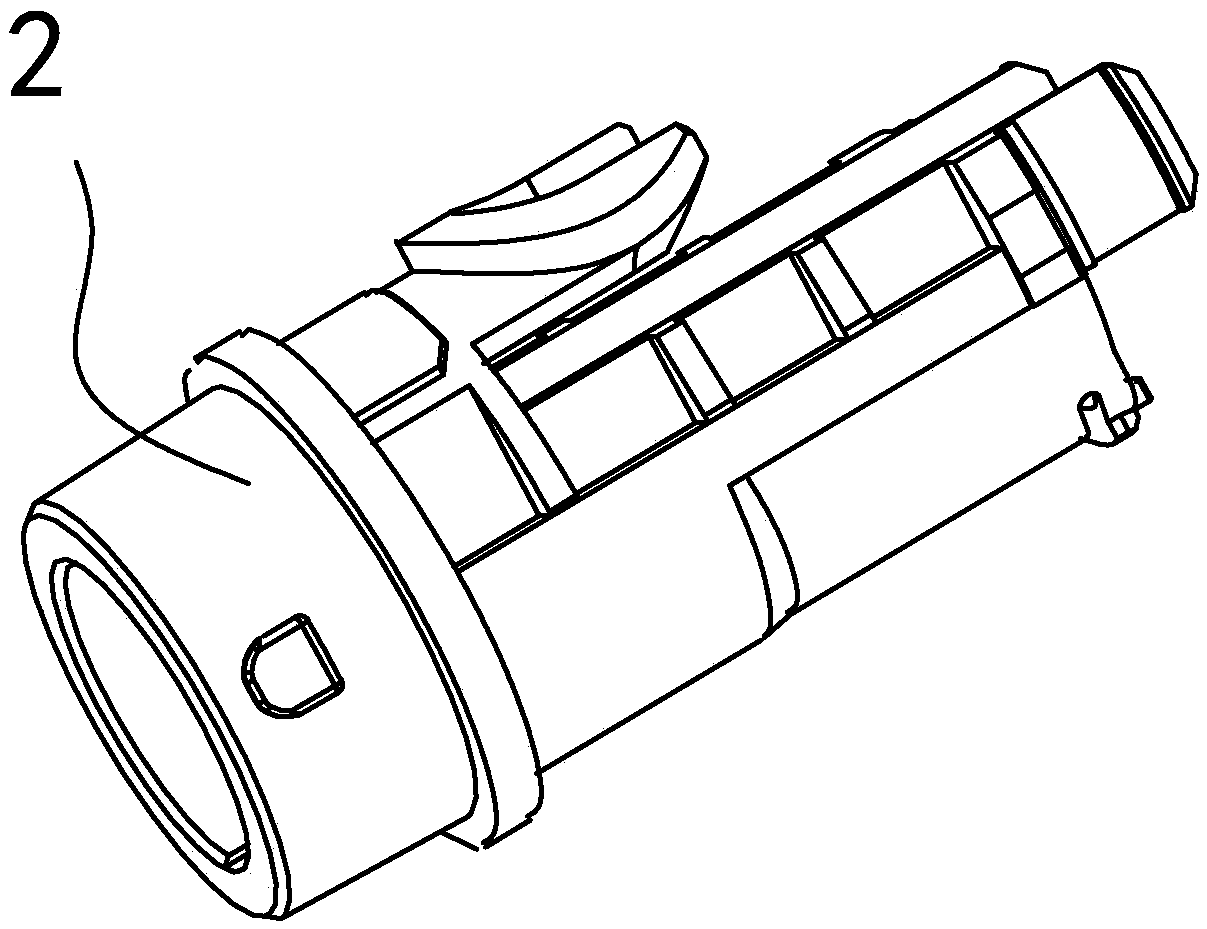

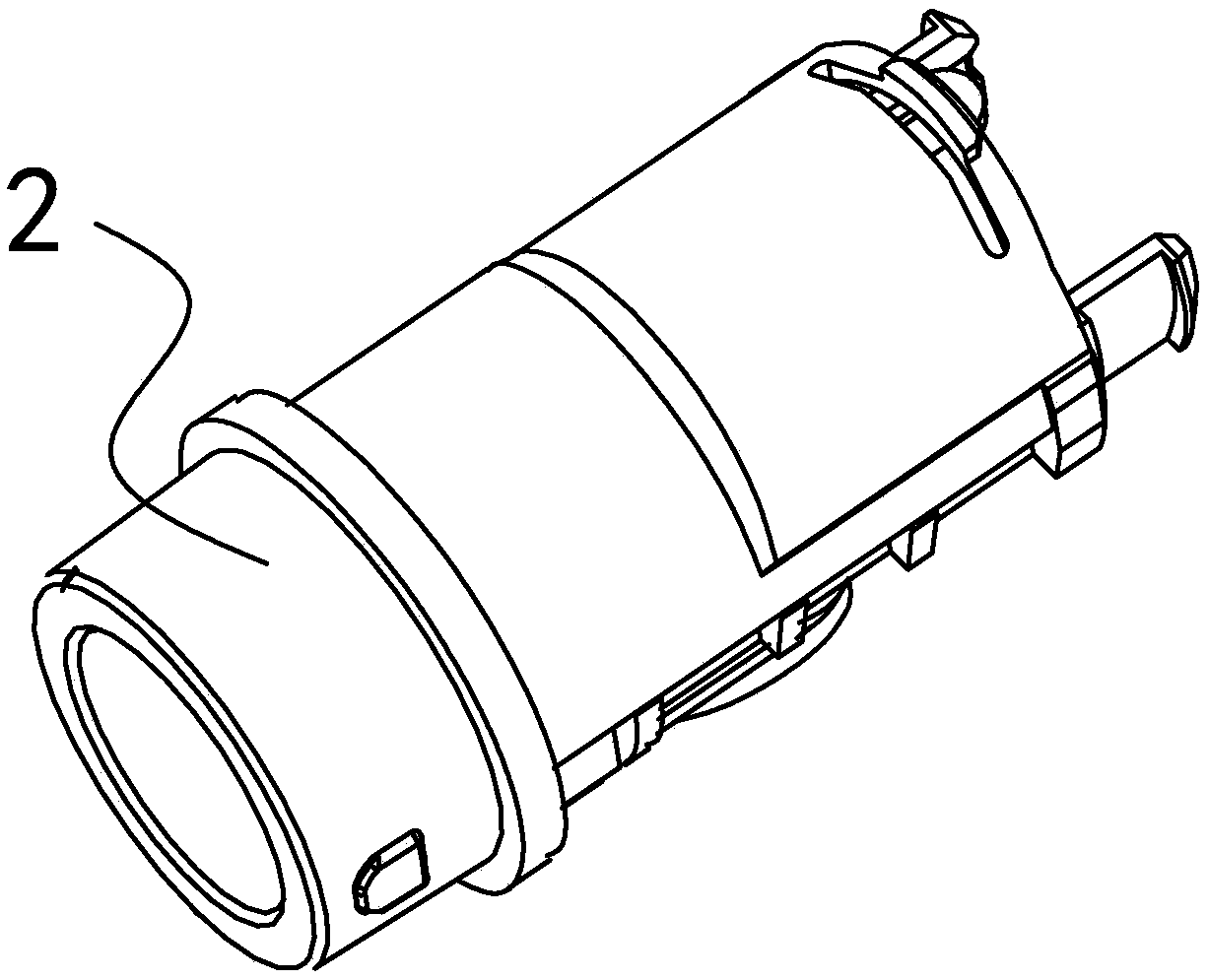

Dismounting-free cap assembling and disassembling needle type blood sampling pen

ActiveCN109512437ASolve the problem of not being able to stretch and become longerSolve the problem of passing through the free capSensorsBlood sampling devicesVariable lengthBlood sampling

The invention relates to a dismounting-free cap assembling and disassembling needle type blood sampling pen, which comprises a shooting rod, an disassembling needle rod and a shell, and is characterized in that the shooting rod is formed by connecting a front shooting rod, a connecting spring and a rear shooting rod to form a variable-length shooting rod; a needle outlet hole at the front end of the blood sampling pen is designed into a assembling and disassembling hole through which a blood sampling needle can pass; the rear shooting rod is provided with a rear rod front limiting structure, so that the rear shooting rod has a limiting distance in forward movement; the front shooting rod is provided with a front rod front limiting structure, so that the front shooting rod has the limitingdistance in the forward movement; and in a needle disassembling state, the limiting distance of the front shooting rod is designed to be larger than the limiting distance of the rear shooting rod. Thedismounting-free cap assembling and disassembling needle type blood sampling pen is characterized in that the blood sampling needle is assembled and disassembled without disassembling a pen cap; andcompared with an original blood sampling pen, a needle assembling process is reduced to one step from original four steps, and a needle disassembling process is reduced to one step from original threesteps. By the adoption of the dismounting-free cap assembling and disassembling needle type blood sampling pen, the problem that the pen cap needs to be repeatedly disassembled and assembled during use of the original blood sampling pen is thoroughly solved, operation steps are greatly simplified, and great convenience is brought to the use.

Owner:STERILANCE MEDICAL SUZHOU

Cultivation method for quickly breeding allium fistulosum

InactiveCN104067835ASpeed up breedingImprove breeding efficiencyPlant genotype modificationHorticultureVernalizationPlantlet

The invention discloses a cultivation method for quickly breeding allium fistulosum. The cultivation method mainly comprises the steps that cultivation at different places is reasonably arranged, allium fistulosum seeds are sown at a cold area which is suitable for allium fistulosum growth at the seedling stage, it is guaranteed that the average stem diameter of the allium fistulosum can reach 1-2 cm after the allium fistulosum seeds are sown for about 90 days, the natural environment when the first frost date approaches at the local place is fully utilized, so that the allium fistulosum is subjected to vernalization smoothly, plants are transported to the area with the temperature being 20-30 DEG C for field planting, the plants can enter in a reproductive growth stage smoothly, the allium fistulosum blooms after field planting is conducted for 30-40 days, and fruitage can be achieved after 60 days; the first alternation of generations of the allium fistulosum can be completed within six months; afterwards, harvested seeds are sown continuously, the temperature is controlled within the range of 10-25 DEG C, it is guaranteed that the average stem diameter of the allium fistulosum can reach 1-2 cm after sowing is conducted for about 90 days, field planting is carried out in the natural environment at the early spring, sudden change of seasons and air temperatures is utilized ingeniously to enable the allium fistulosum to enter in the reproductive growth stage through vernalization, and fruitage is achieved after field planting is conducted for 60-80 days; the rapid two-generation breeding process of the allium fistulosum can be realized in one year. By means of the cultivation method for quickly breeding allium fistulosum, the breeding speed of the allium fistulosum can be greatly increased.

Owner:天津市园艺工程研究所

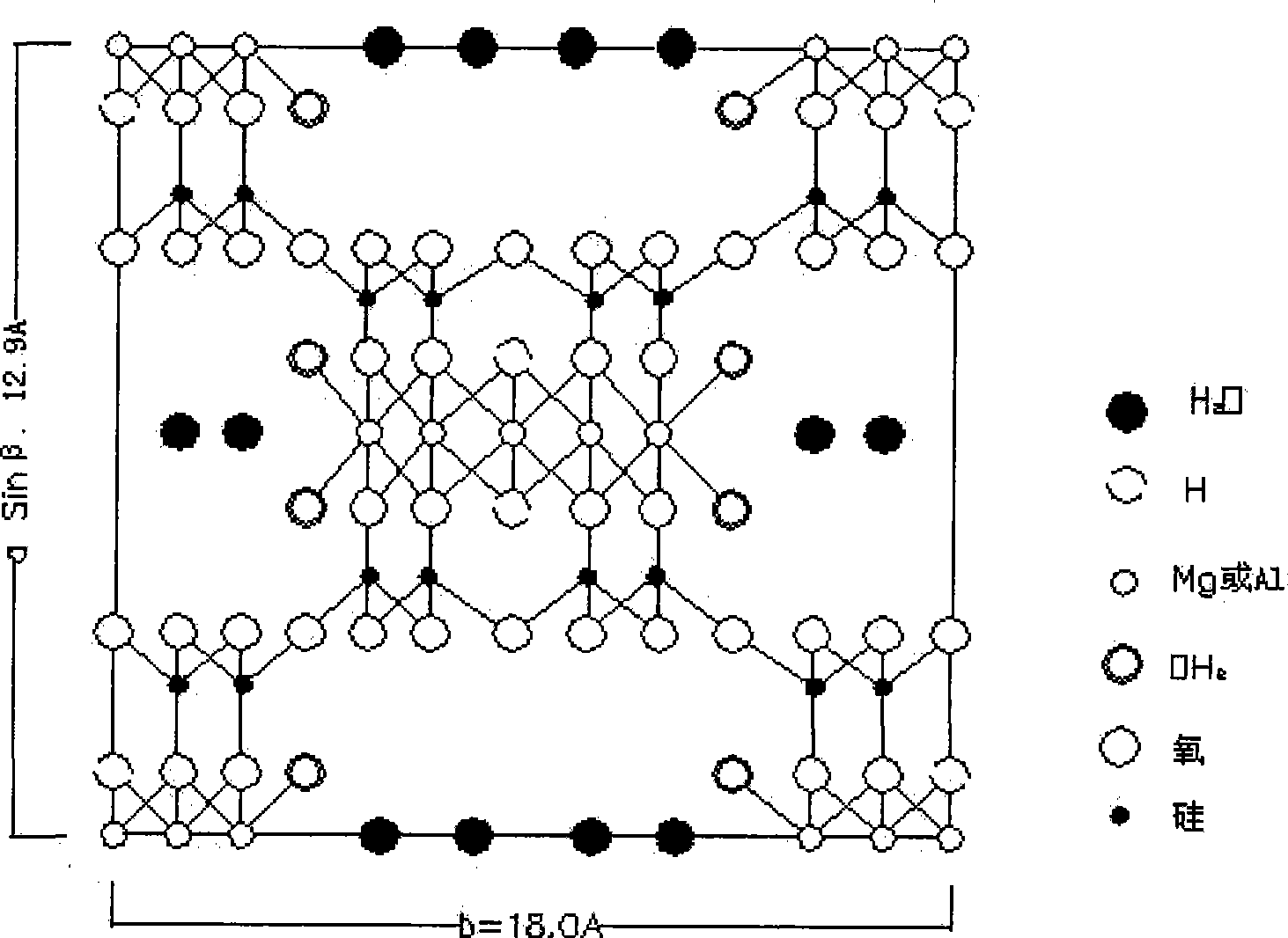

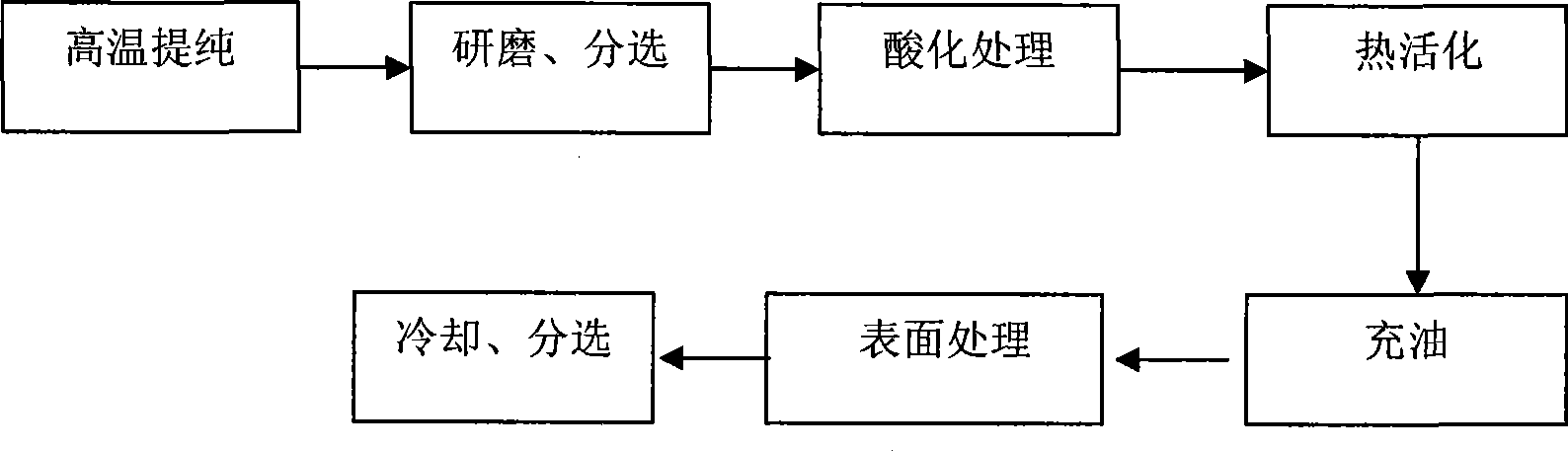

Inorganic high molecular plastics and rubber toughening agent

The invention provides an inorganic polymer rubber-plastic toughener using attapulgite clay as a main raw material, which is evenly dispersed in a high polymer matrix, and has good compatibility with high polymer. The method for preparing the inorganic high polymer rubber-plastic toughener comprises the following steps: (1) purifying the attapulgite clay at a high temperature; (2) grinding and sorting; (3) acidizing; (4) thermal activating; (5) oil charging; and (6) surface treating. The toughener uses the property of fibrous microcellular structure of the attapulgite clay, modifies fibrous pore canals of inner layers of particles, improves the compatibility of the toughener with the high polymer on the premise that the fibrous structure of the attapulgite clay is maintained, has unique modification function, not only replaces toughener resin, but also proves that compared with the prior combination of padding / toughener resin, a plastic product blended by the inorganic high polymer rubber-plastic toughener and a plurality of synthetic resins has preferable aging resistance and physical property through a plurality of applied tests.

Owner:NANJING YADONG AOTU MINING

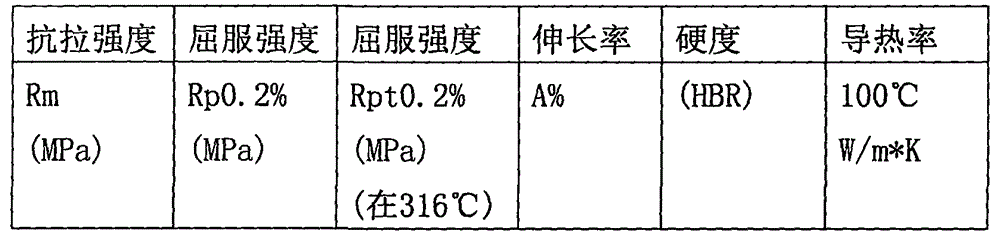

Heat-resistant steel sheet for power station boiler and manufacturing method thereof

The invention relates to a heat-resistant steel sheet for a power station boiler and a manufacturing method thereof. The steel sheet comprises the following components in percentage by mass: 0.08-0.12% of C, 0.15-0.45% of Si, 0.35-0.55% of Mn, less than or equal to 0.013% of P, less than or equal to 0.005% of S, 8.60-8.90% of Cr, 0.31-0.50% of Mo, 0.16-0.22% of V, 1.55-1.85% of W, 0.045-0.085% of Nb, 0.045-0.065% of N, 0.002-0.004% of B, 0.20-0.35% of Ni, greater than 0 and less than or equal to 0.01% of Al and greater than 0 and less than or equal to 20ppm of O. The performance of the steel sheet reaches the application requirements and the width of the steel sheet reaches 2000-3000 mm. The manufacturing method sequentially comprises the following steps: preparing billet materials, casting a continuous casting billet; annealing at an annealing temperature of 740 + / -10 DEG C; carrying out hot grinding; heating the steel billet at a heating temperature of 1230 + / -10 DEG C; (V) rolling at a rough-rolling starting temperature of 1160-1200 DEG C and the finish rolling temperature of 860-900 DEG C; (VI) carrying out heat straightening; (VII) normalizing at a normalizing temperature of 1050 + / -10 DEG C; and (VIII) tempering at a tempering temperature of 780 + / -10 DEG C, carrying out heat preservation, discharging the steel sheet out of a furnace and carrying out air cooling. The manufacturing method is high in finished product rate and low in cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

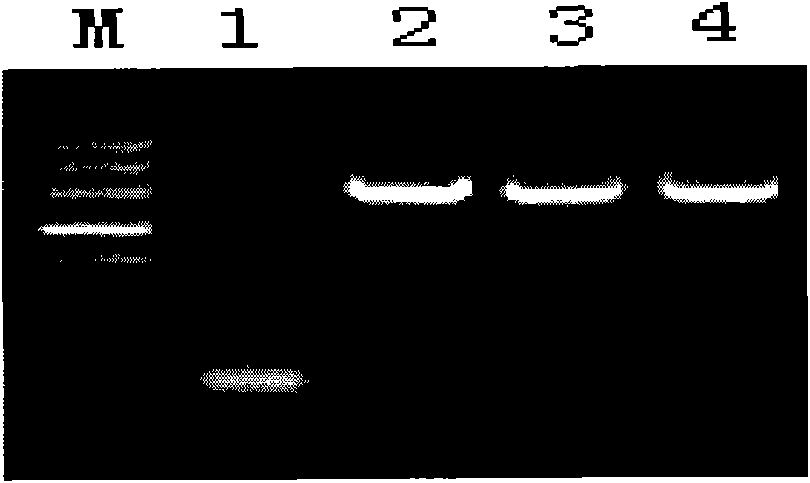

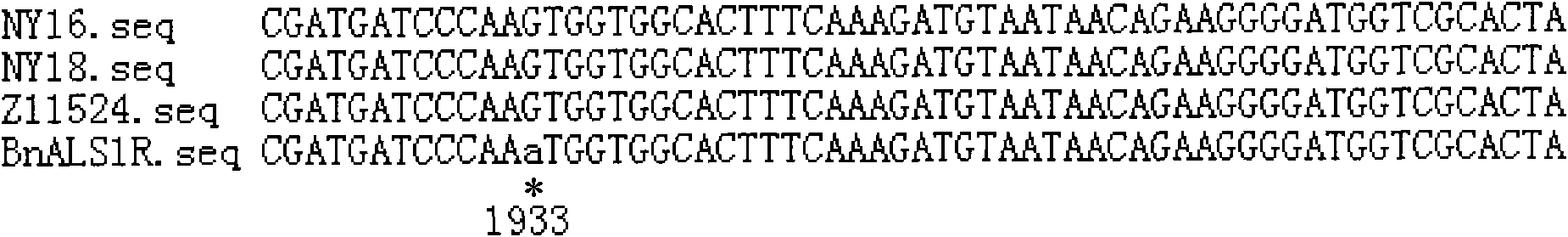

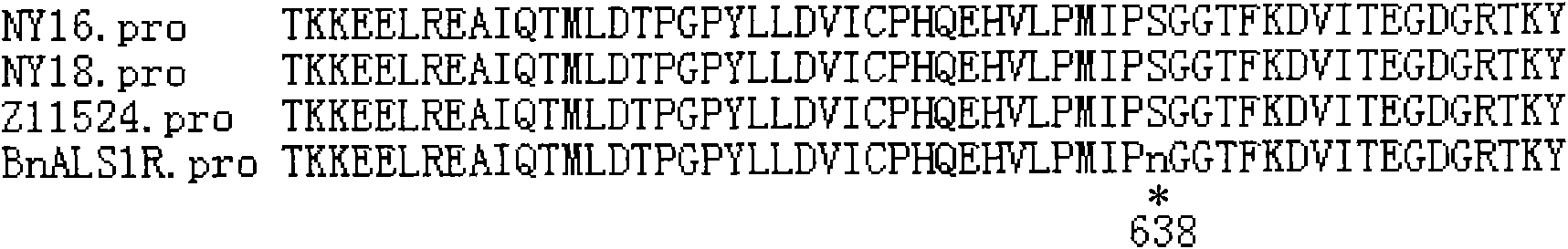

Brassica napus mutator gene for resisting imidazolone weedicide and application thereof

The invention discloses a brassica napus mutator gene for resisting imidazolone weedicide and application thereof, relating to the field of plant molecule breeding. Primer pairs are utilized to carry out PCR (Polymerase Chain Reaction) proliferation by using a mutant M9 of brassica napus for resisting imidazolone weedicide as a material to obtain a mutator gene of the mutant with the sequence number of SEQ ID NO.1; and proteins are acquired by translation of the gene with an amino acid sequence of SEQ ID No.2. By applying the conventional breeding method of crossbreeding plants, backcrossing plants and the like, the gene is introduced into other napus varieties or variety series having no resistance to the imidazolone weedicide, so as to improve the durability on the imidazolone weedicide by introducing ALS gene mutation nucleotide sequence target varieties or variety series.

Owner:JIANGSU ACAD OF AGRI SCI

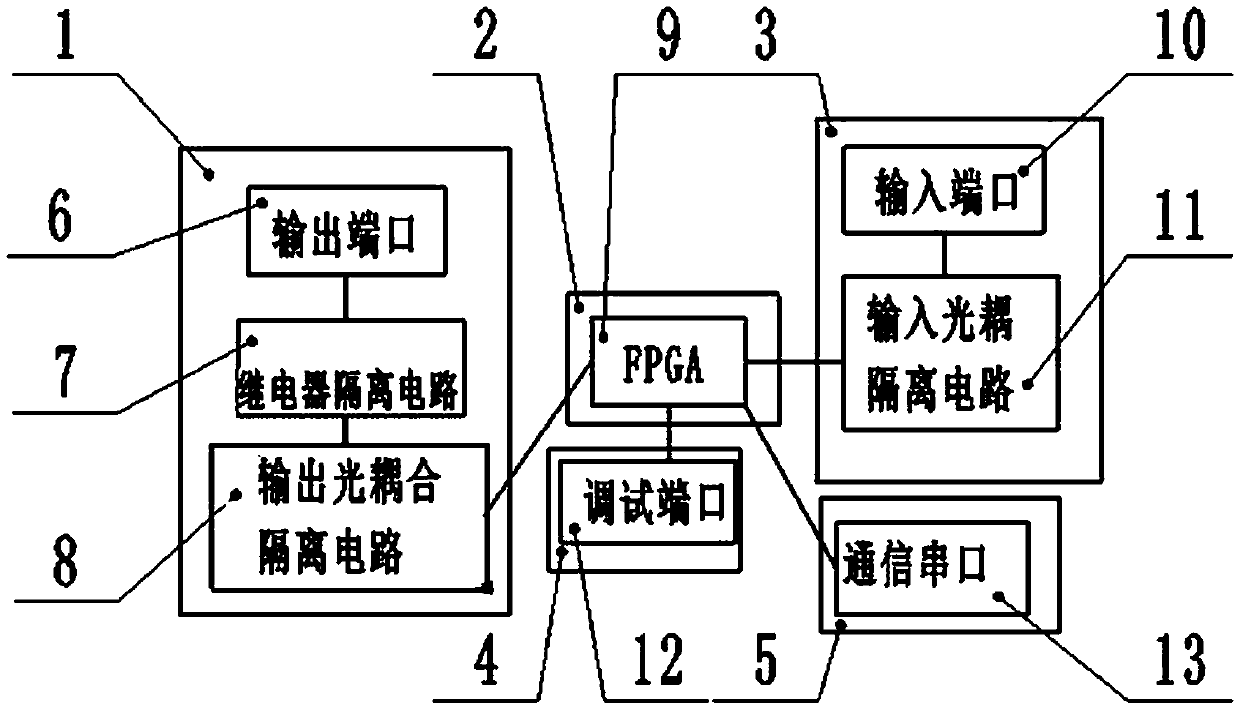

Method and device for achieving PLC controlling in FPGA platform

ActiveCN105511394AImprove real-time performanceOvercome closureProgramme control in sequence/logic controllersComputer scienceVerilog

The invention discloses a method and device for achieving PLC controlling in an FPGA platform. The method is converted into Verilog HDL programs through an ST2FP resolver, not only can input and output logic of a PLC be correctly achieved, but also the programs can run in the FPGA platform in parallel, therefore, the mode that a traditional PLC only can sequentially scan executive programs is fundamentally changed, the PLC program execution time is not related to the size of the programs but only related to the depending level of the programs, and the program execution efficiency of an FPGA-PLC is incomparable for the traditional PLC. According to the device, an IEC-61131-3 standard is applied to the FPGA-PLC, the defects that the traditional PLC is poor in closing property and compatibility are overcome, breaking of the monopoly situation of high-end PLC manufacturers is facilitated, the characteristic that the FPGA executes the programs in parallel is also facilitated, therefore, the FPGA-PLC can execute the PLC programs in parallel, and the real-time performance of the PLC is significantly improved; processing of the FPGA is the implementation process of pure hardware, and therefore the FPGA-PLC system has the very high stability.

Owner:GUILIN UNIV OF ELECTRONIC TECH

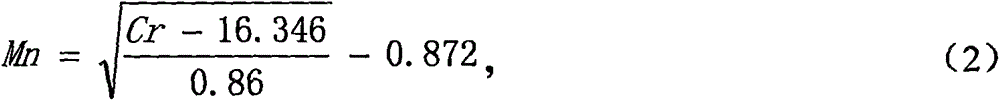

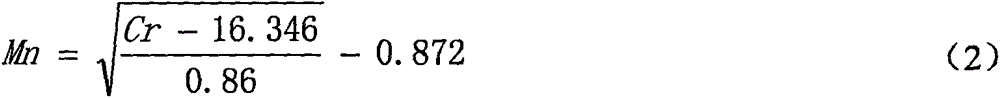

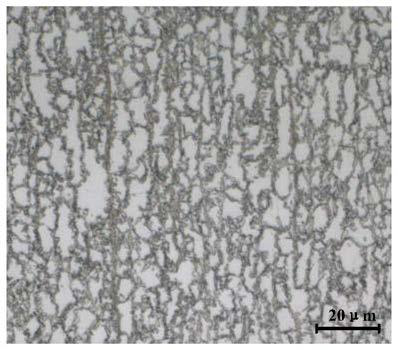

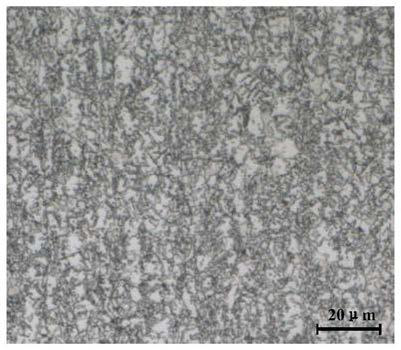

Ferritic stainless steel and manufacturing process thereof

The invention discloses ferritic stainless steel and a manufacturing process thereof. The ferritic stainless steel comprises Fe and modified chemical elements. The modified chemical elements comprise, by weight percentage, 0-0.02% of C, 0-0.55% of Si, 0-0.25% of P, 0-0.006% of S, 0-0.40% of Ni, 0-0.06% of Cu, 0-0.04% of Al and 0-0.02% of N and further comprise Cr, MN, Mo and Ti, wherein the mass percentage of Mo is not smaller than 0 and not larger than 0.05. The weight percentages of Cr, Mn and Mo have the following relations: Mo=1.063-1, 0<=Mo<=0.05%, another equation here as shown in the specification, and 0.20%+4(C+N)%<=Ti<=0.50%. The ferritic stainless steel is resistant to corrosion and erosion. According to the manufacturing process, the hardness of the ferritic stainless steel can be adjusted, so that the ferritic stainless steel can be applied to a heat exchanger of a nuclear power station, the situation that the material is monopolized by foreign countries is broken, and the cost is reduced.

Owner:浙江润都能源科技有限公司

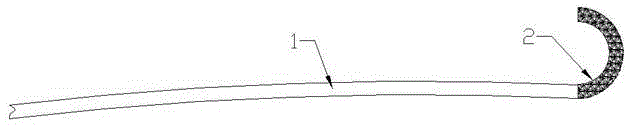

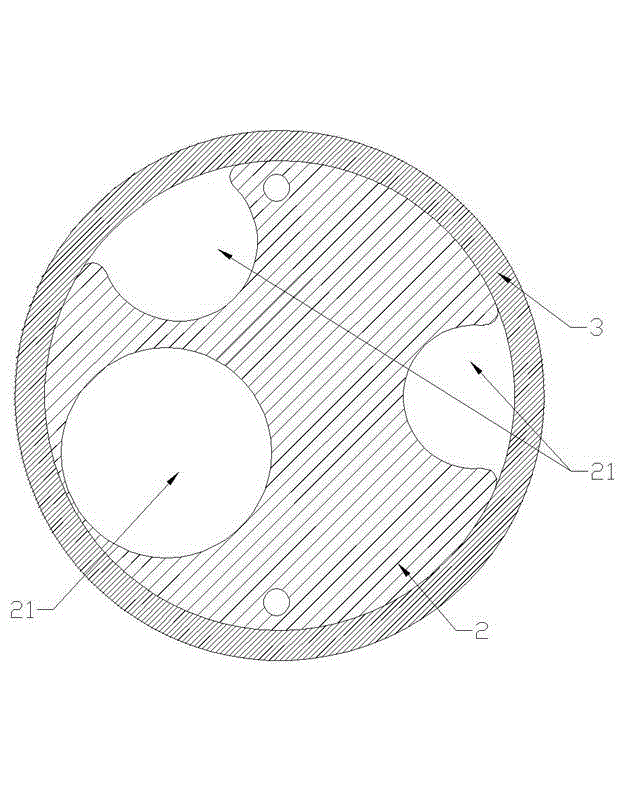

Processing method for endoscope and endoscope

ActiveCN104545771AQuick installationLow costEndoscopesTelescopesUltimate tensile strengthBiomedical engineering

The invention discloses a processing method for an endoscope and the endoscope prepared according to the processing method. The processing method for the endoscope is high in intensity, convenient to mount, high in manufacturing efficiency and low in cost. The processing method for the endoscope includes steps that (1) manufacturing an inner core, to be specific, forming a plurality of grooves in raw material of the inner core, wherein the grooves serve as holding cavities for endoscope components; (2) mounting components, to be specific, placing the components of the endoscope in the corresponding grooves, and fixing. The endoscope prepared by the method comprises a tip structure (1) and an insert tube, the insert tube comprises an inner core (2), a plurality of grooves (21) are formed in the inner core (2), and the endoscope components are arranged in the grooves (21). The processing method for the endoscope and the endoscope can be used for the endoscope equipment field.

Owner:ZHUHAI PUSHENG MEDICAL SCI & TECH

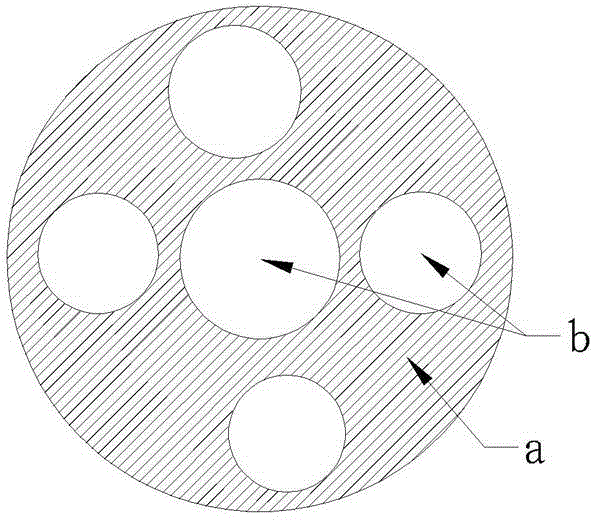

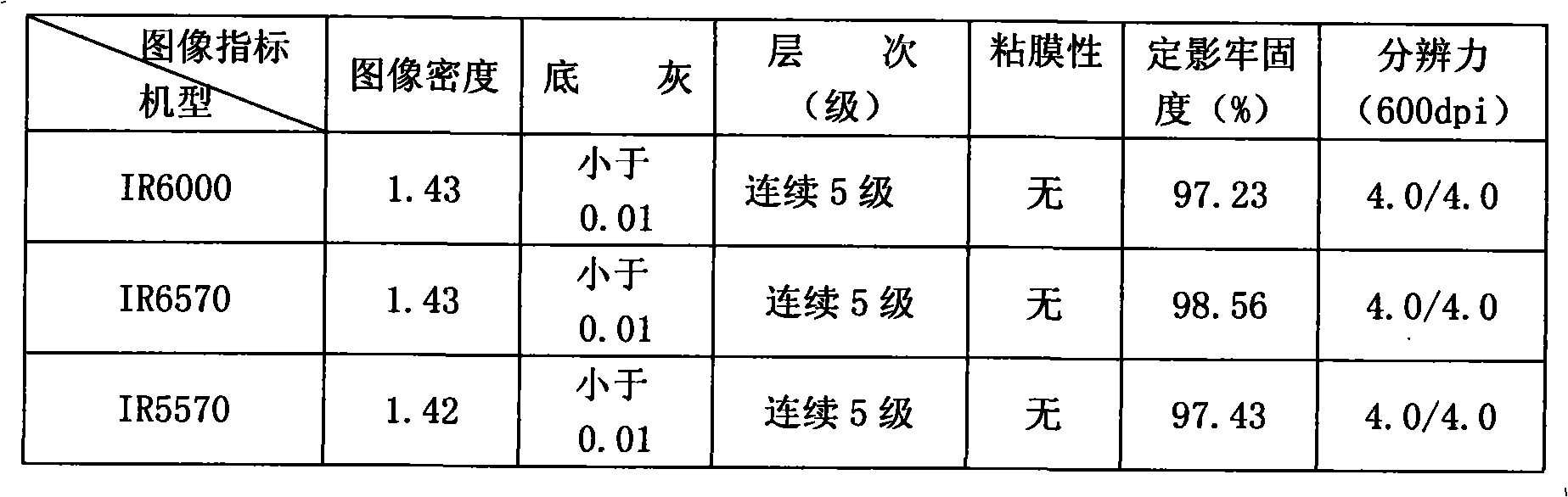

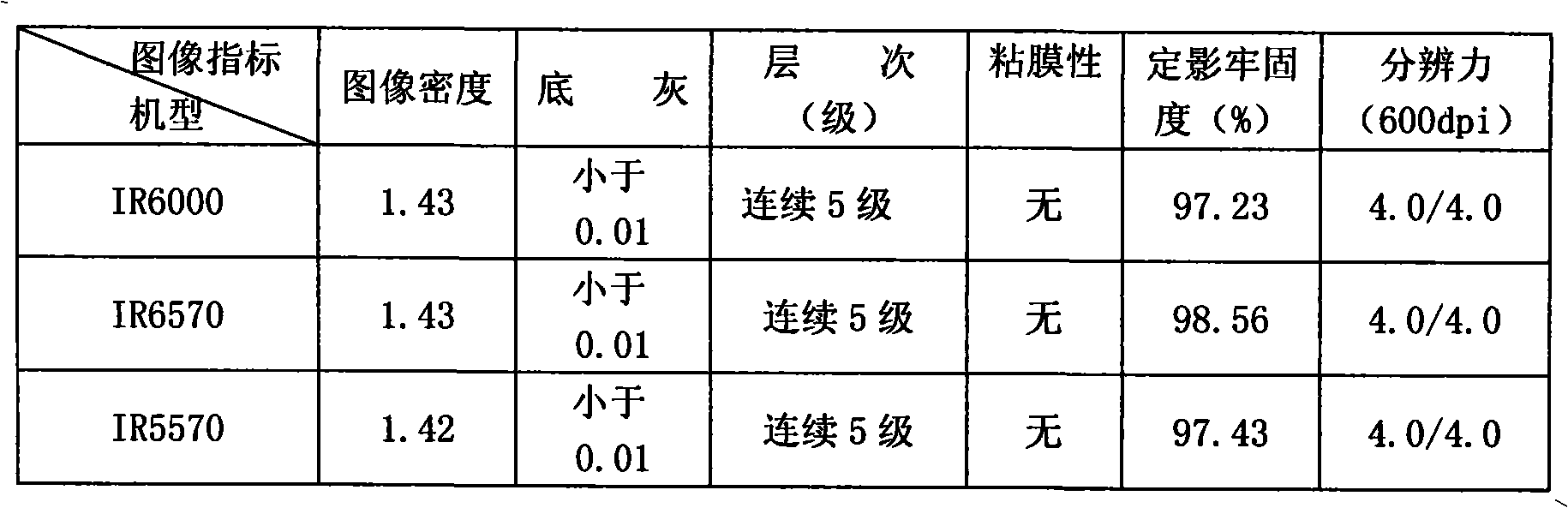

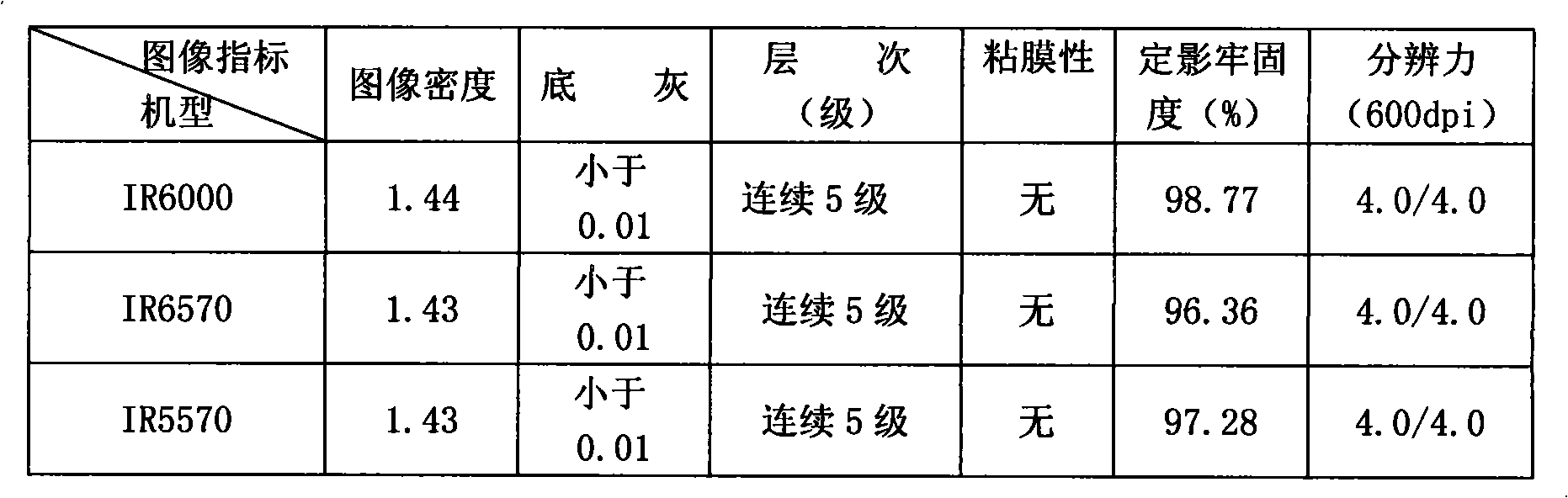

Electronegative one-component developing agent

The invention relates to electronegative one-component developing agent used for a high-speed digital copier. The developing agent has the following components by weight ratio: 30-65% of polyester resin, 30-55% of magnetic powder, 2-8% of polypropylene wax, 0.3-3% of charged modifier, and 0.5-4% of external addictive, wherein, the polyester resin is formed by mixing high softening point polyester resin and low softening point polyester resin, and the polypropylene wax is formed by mixing two waxes with different softening points. The produced electronegative one-component developing agent can be used for the high-speed digital copier; the indexes of image density, resolution, level, bottom ash, mucosal property, firm fixation and the like reach the international standard, thus breaking monopoly positions of large international companies on novel digital copier ink powder market and supplying the gap of home and abroad compatible market.

Owner:TIANJIN ZHONGHUAN TIANJIA ELECTRONICS

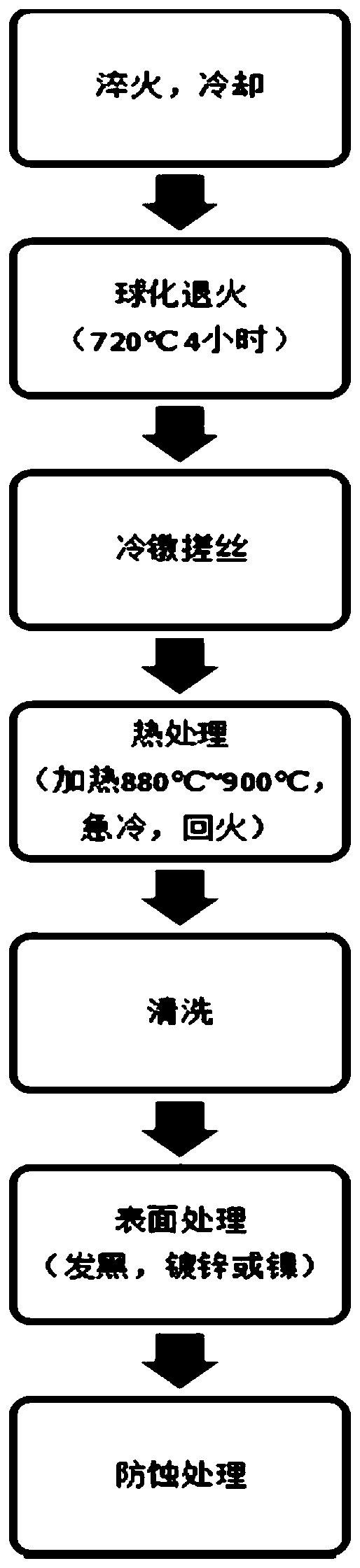

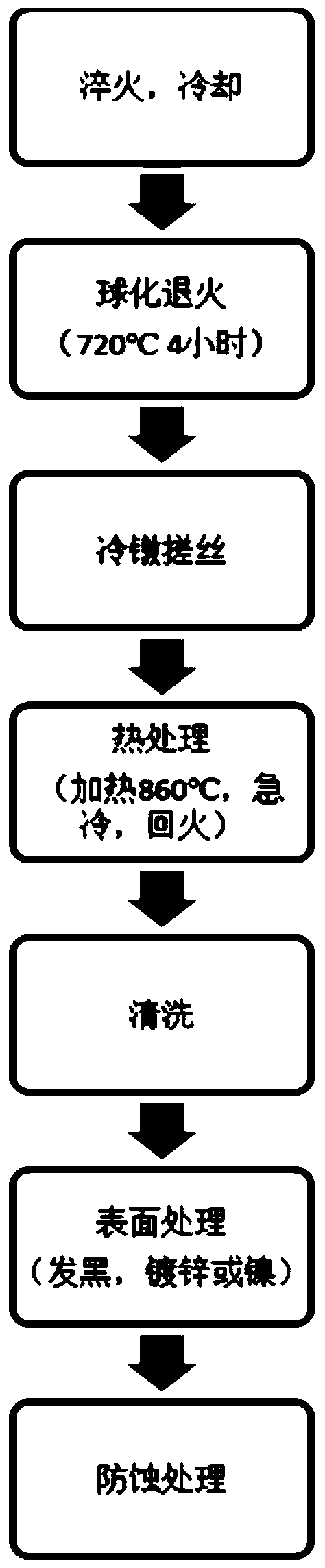

Manufacturing process of ultrahigh-strength fastener

InactiveCN111363893AGood value for moneySave foreign exchangeWashersNutsTemperingManufacturing technology

The invention discloses a manufacturing process of an ultrahigh-strength fastener. The manufacturing process creatively adopts extremely common domestic steel 20MN2 and 30MN2, and the manufacturing process comprises the following steps of quenching, cooling, spheroidizing annealing, cold heading and thread rolling, carrying out heat treatment (heating, quenching and tempering), cleaning, carryingout surface treatment (blackening, galvanizing or nickel plating) and carrying out anti-corrosion treatment. The ultrahigh-strength fastener which is used by outer enterprise and is made of extremely-high-quality steel is manufactured, the monopoly position of the imported high-strength fastener is broken, the cost performance is extremely high, and the domestic blank is filled. At present, fastener production in China has large-scale enterprises, fasteners of 10.9 level and below are generally produced, the 12.9-level national standard fasteners exist, but almost no enterprise capable of producing and manufacturing the fasteners reaching 12.9-level national standard exists. The ultrahigh-strength nut and the ultrahigh-strength bolt are used in cooperation, the mechanical and physical properties are similar, and the manufacturing process is the same.

Owner:金晓亮 +1

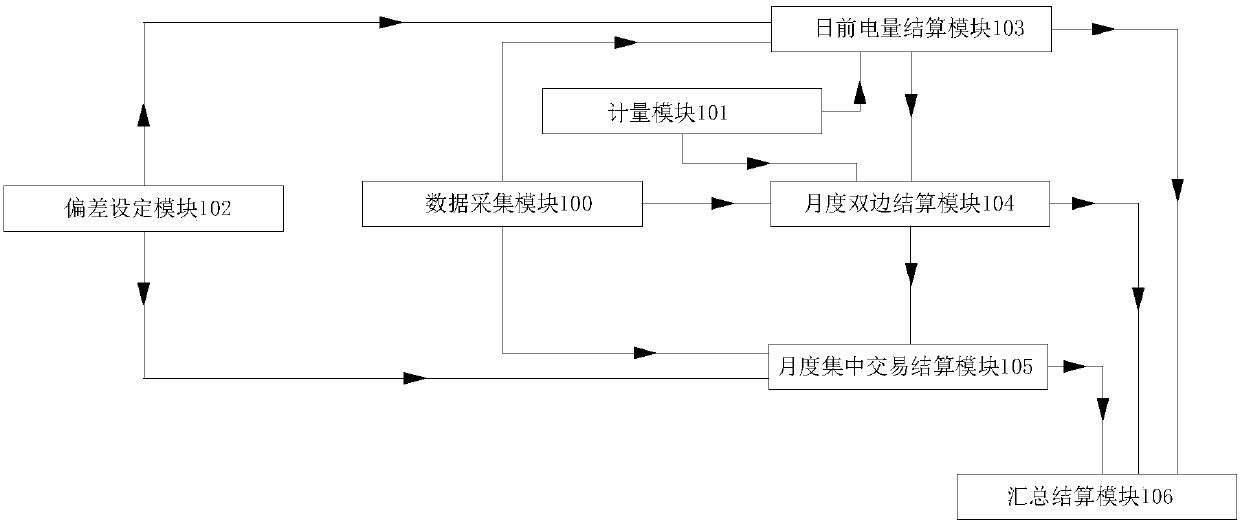

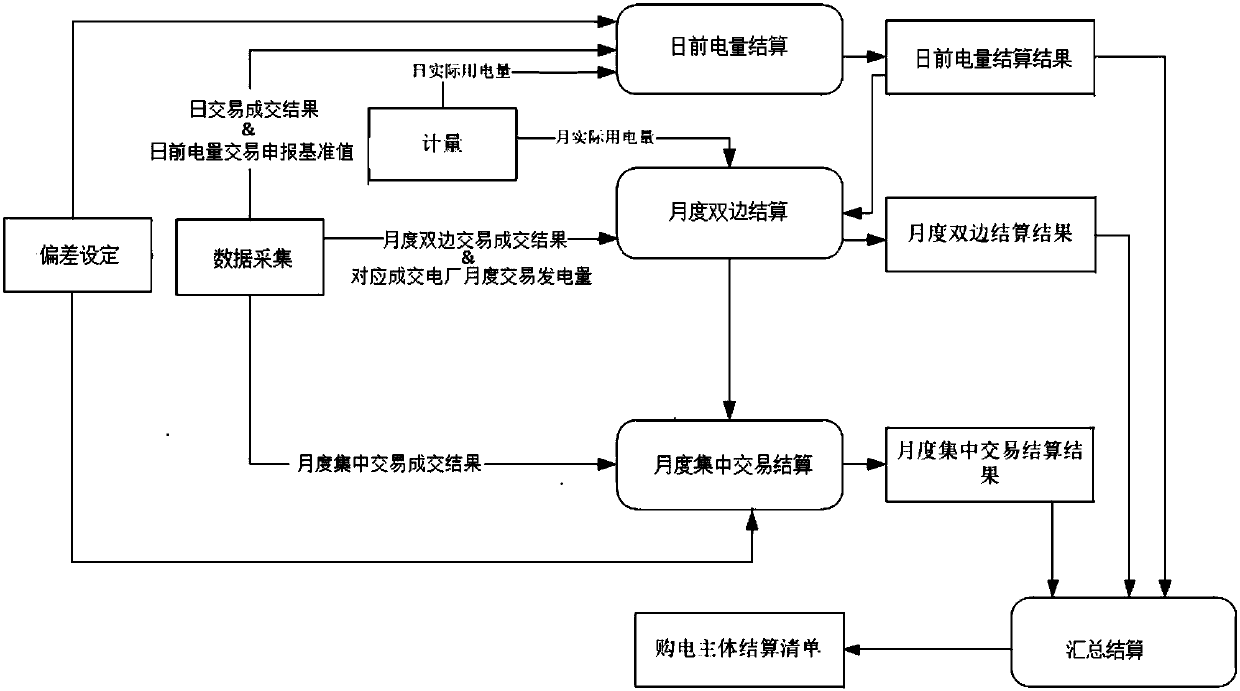

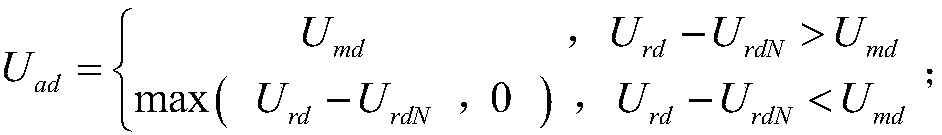

Settlement system and method for electricity purchase subject in regional electricity market

ActiveCN107301537ABreak the monopolyNovel structurePayment architectureElectricity priceElectricity market

The invention relates to a settlement system and method for an electricity purchase subject in a regional electricity market, and belongs to the technical field of electric power systems. The system comprises a data collection module, a metering module, a deviation setting module, a day-ahead electricity settlement module, a monthly bilateral settlement module, a monthly centralized trading settlement module and a summarization settlement module. The system is novel in structure; the settlement process is reasonable and efficient; and through electricity price competition permission and electricity distribution and selling subject permission, effective technical support is provided for gradually nurturing multiple marketized competition patterns, breaking the monopolistic situation of a power grid company and forming an advanced electricity utilization transaction settlement mechanism.

Owner:昆明电力交易中心有限责任公司

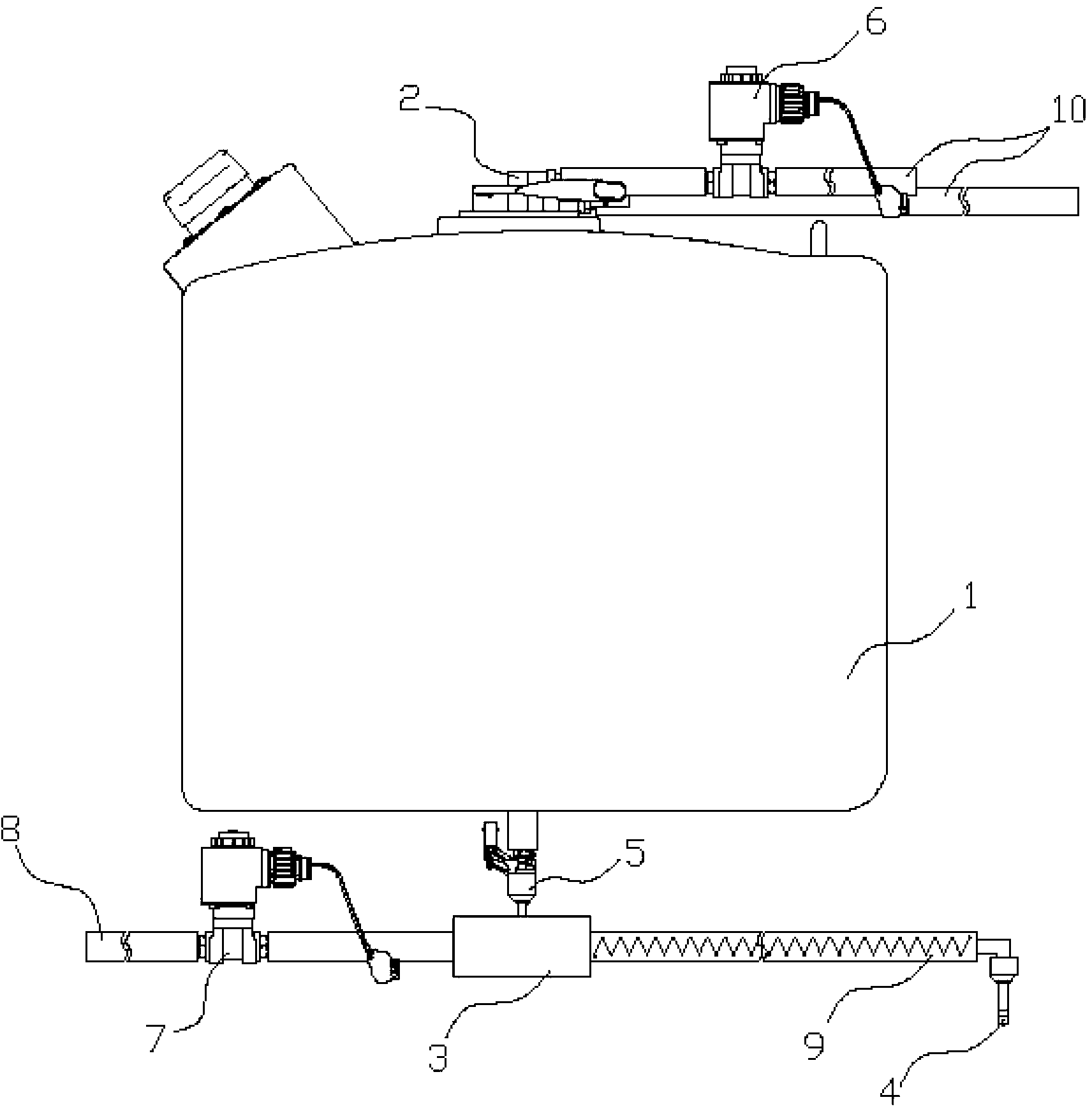

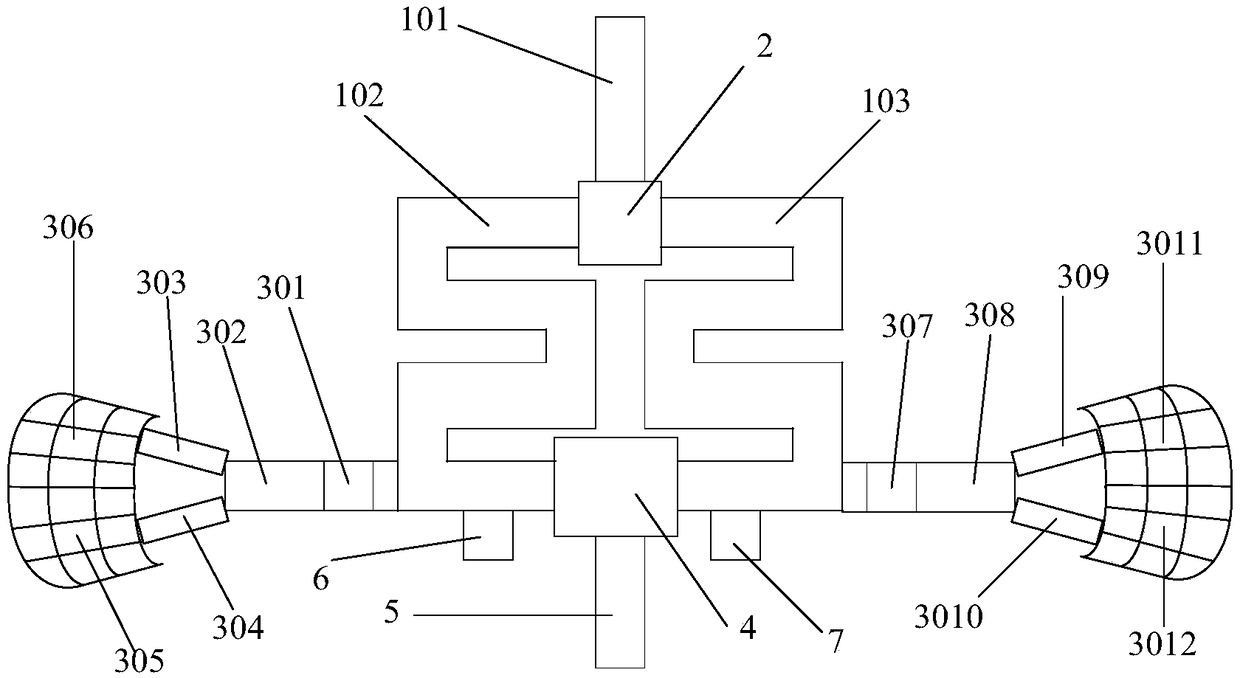

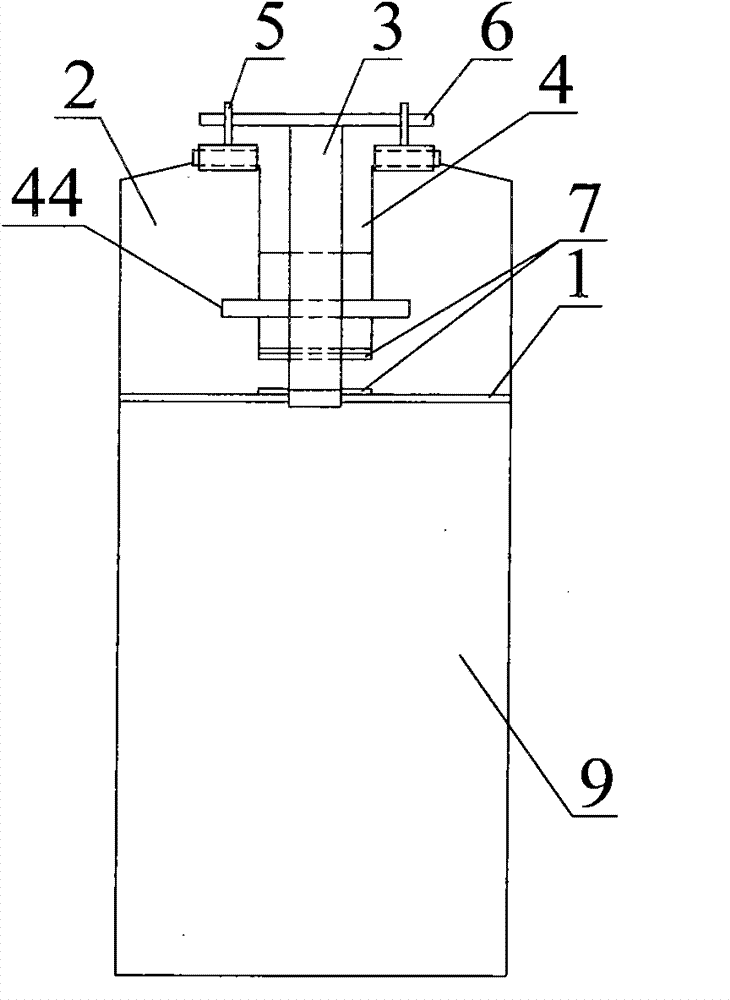

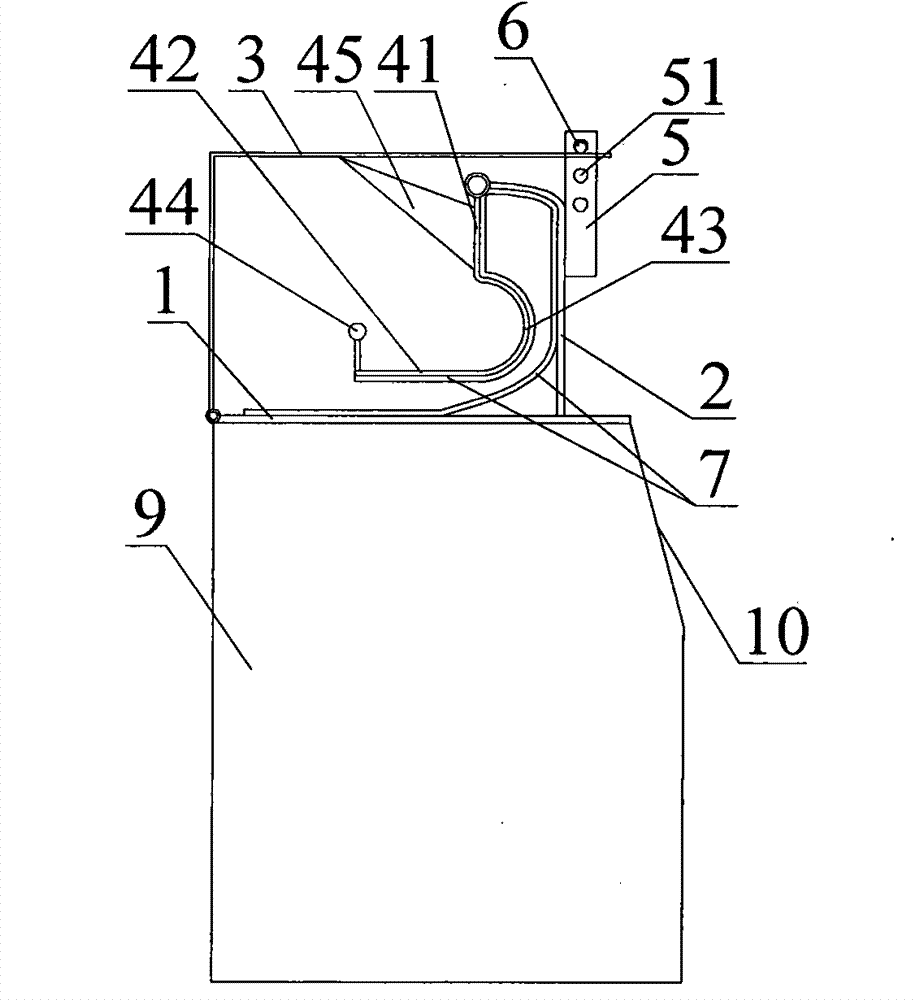

Gas-assisted urea injection system with mixing tube heating method adopted

InactiveCN103266938AReduced risk of crystallizationReduce the manufacturing process cost of exhaust pipelineExhaust apparatusSilencing apparatusUreaWater pipe

The invention discloses a gas-assisted urea injection system with a mixing tube heating method adopted, and belongs to the technical field of design of an automobile urea injection system. The gas-assisted urea injection system comprises a urea box (1), a urea box temperature and liquid level sensor (2), a heating control valve (6) and a heating water pipe (10), wherein the heating control valve (6) and the heating water pipe (10) are used for exchanging heat of the urea box (1). The gas-assisted urea injection system is characterized in that a urea metering valve (5) which is separated from a nozzle (4) is installed at the bottom of the urea box, a mixing cavity (3) is connected with the lower end of the urea metering valve (5), one end of the mixing cavity (3) is in pipeline connection with an air pipe (8) through a gas control valve (7), and the other end of the mixing cavity (3) is in pipeline connection with the nozzle (4) through a heating mixing tube (9). The gas-assisted urea injection system removes rigorous requirements for an air exhaust pipeline in the hydrolytic process of a urea solution, is simple in structure, facilitates overall arrangement, reduces crystallization risks of the urea solution, improves system reliability, breaks the situation that international suppliers monopolize, and fully plays technology and market competitiveness of independent products.

Owner:CHINA FIRST AUTOMOBILE

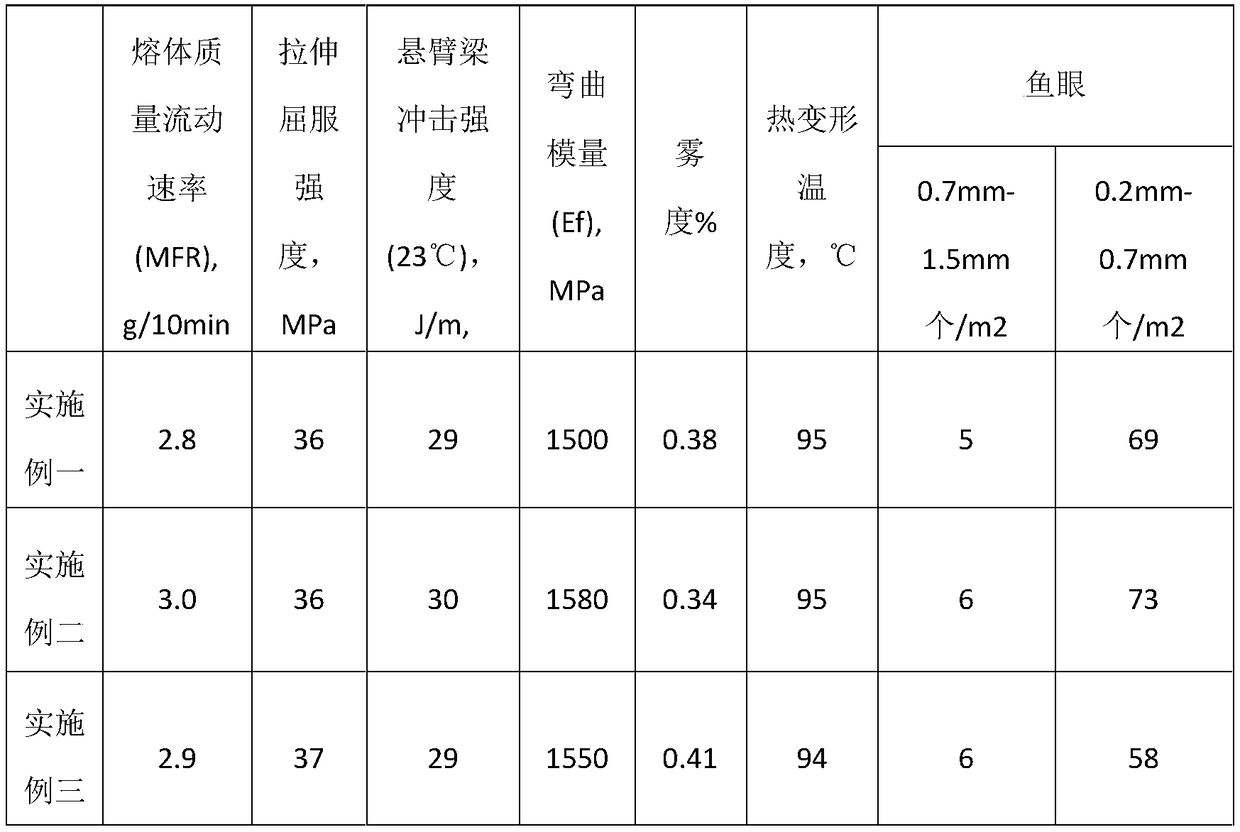

Polypropylene material for stretched film and preparation method of polypropylene material

ActiveCN109467825AStable qualityIncreased flexural modulusBulk chemical productionHalogenPolypropylene

The invention discloses a polypropylene material for a stretched film. The polypropylene material for the stretched film comprises the following components: 99.3-99.86 parts of polypropylene resin powder, 0.05-0.2 part of an antioxidant 1010, 0.03-0.1 part of an auxiliary antioxidant U626, 0.01-0.1 part of a halogen absorbent and 0.05-0.3 part of an alpha nucleating agent. The polypropylene material for the stretched film has higher stiffness and transparence than those of the conventional material and is applicable to production of a high-end stretched film.

Owner:CHINA PETROLEUM & CHEM CORP

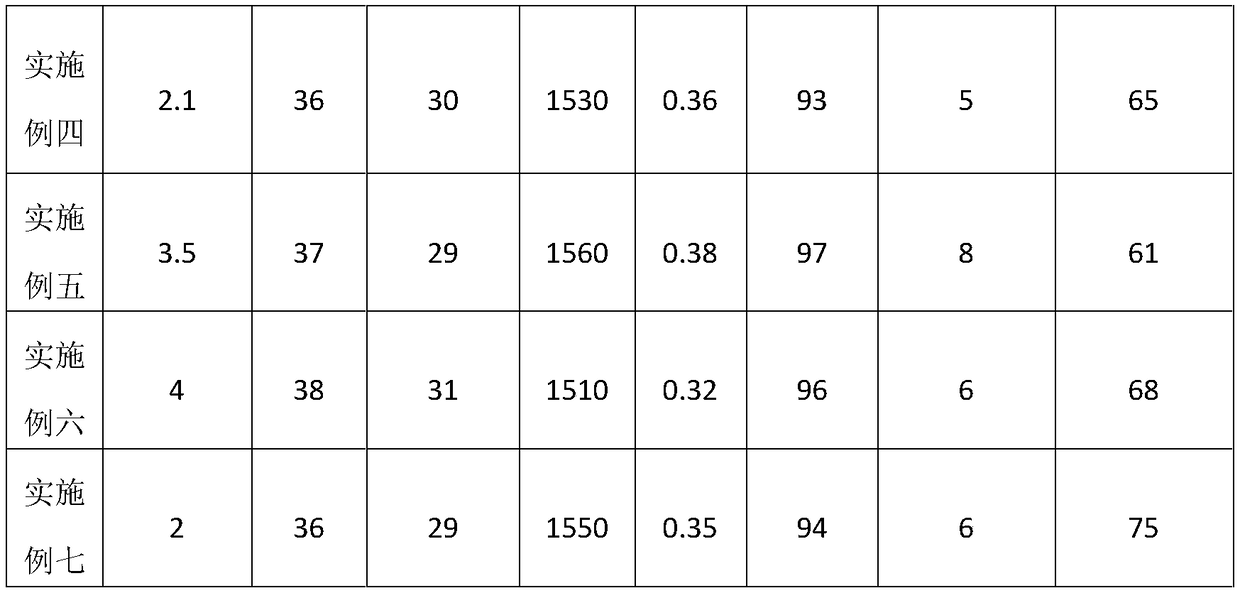

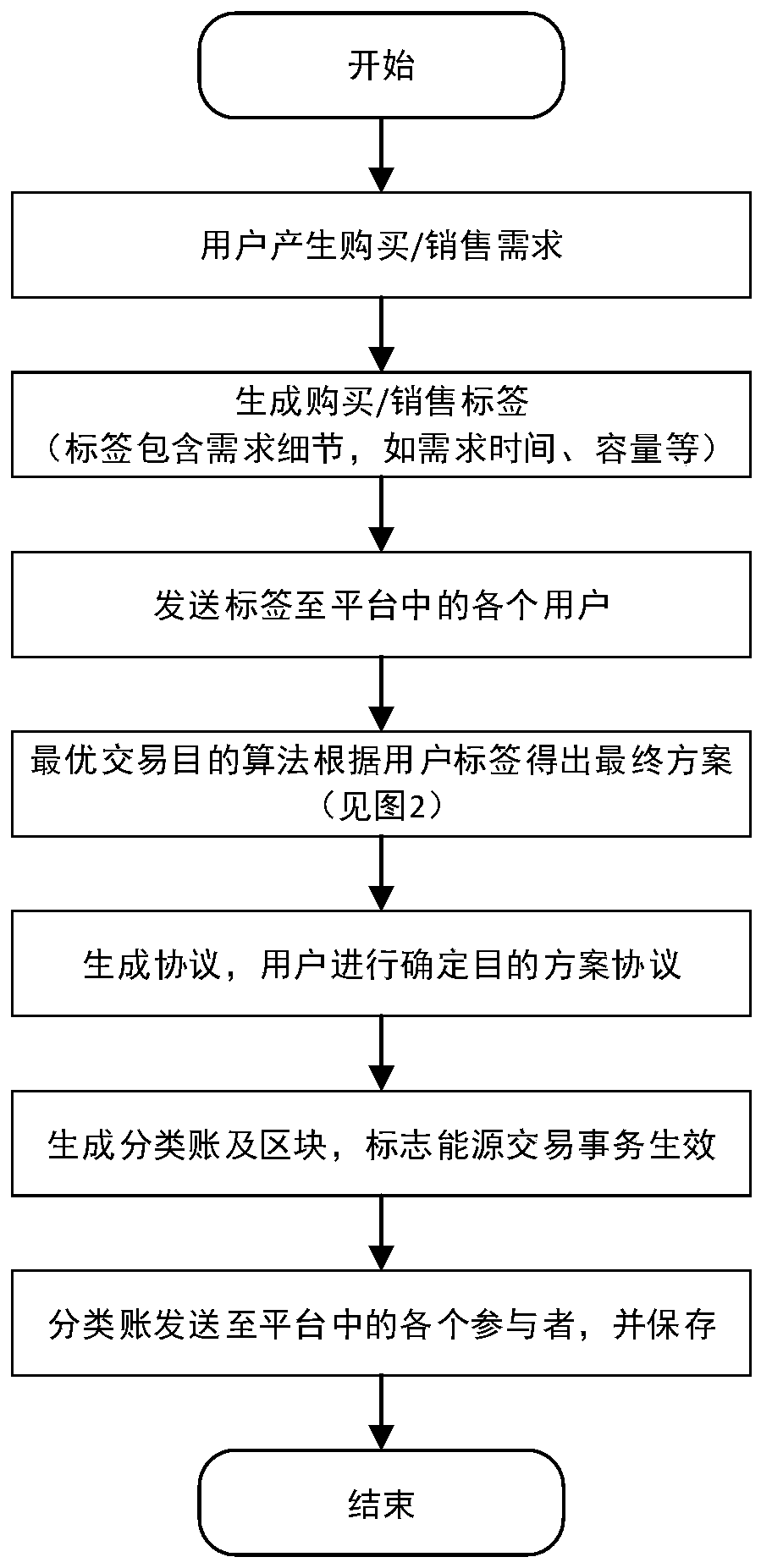

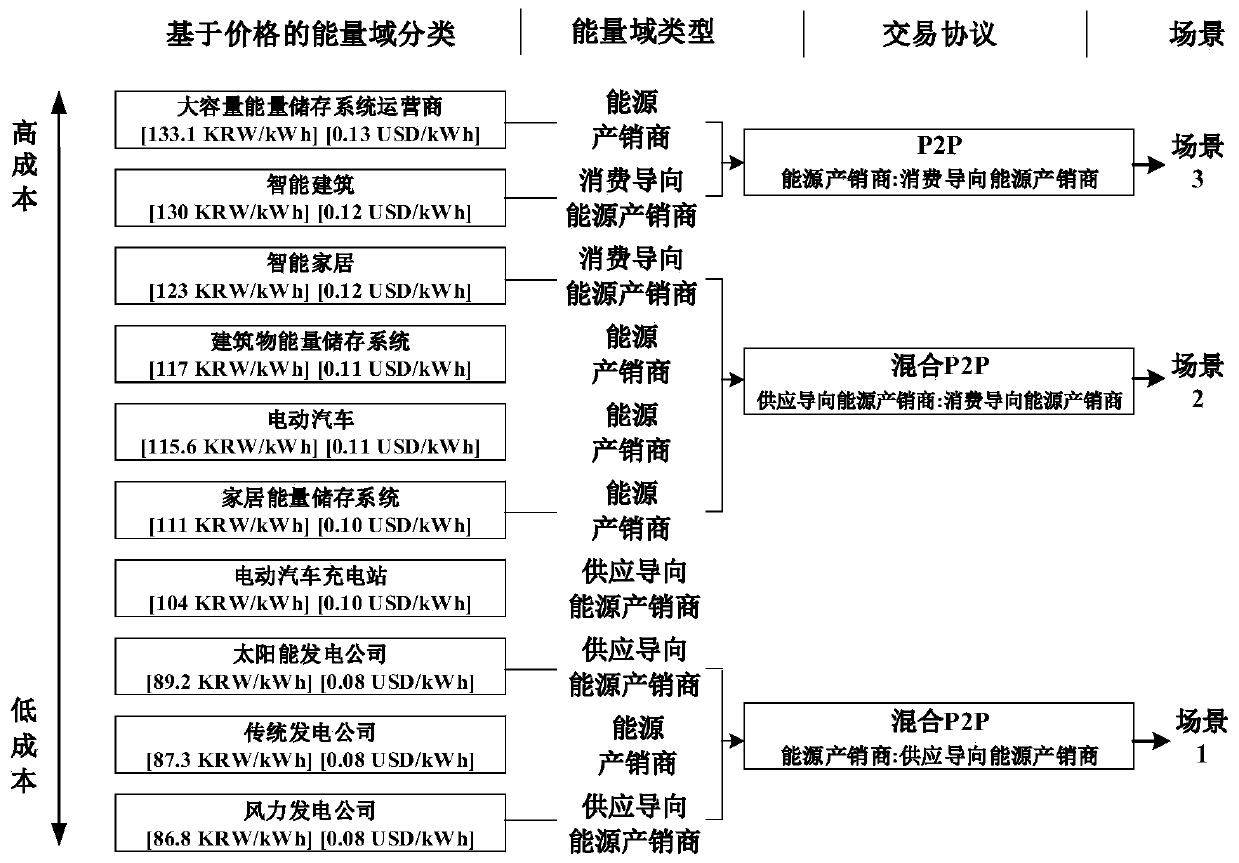

Transaction method of P2P energy transaction platform based on block chain

ActiveCN110246041AQuality improvementLow priceFinanceInformation technology support systemEnergy informationOperating system

The invention discloses a transaction method of a P2P energy transaction platform based on a block chain. The transaction method comprises the following steps: collecting user energy information; generating an energy purchase or sale label; sending the label to an energy transaction platform; selecting the label by a user; confirming the label and a protocol by the user; generating a ledger and a block, after the buyer and the seller confirm the transaction protocol, allocating the label and the protocol to one block, and generating the ledger of the direct energy transaction between the two participated users of the current transaction while the block is generated; and sending the valid ledger to the platform, and adding transaction information stored in the block to the chain. The transaction method can solve the problems that P2P energy transaction safety and efficiency are poor in the prior art, energy cannot be fully utilized due to excessive energy supply of users, so that power generation companies have to take more transformer substations as a means for solving the problem of user growth, and the technical problems of cost and resource waste and the like are caused.

Owner:GUIZHOU POWER GRID CO LTD

Full-automatic intelligent packaging system for chemical fiber DTY spindle

ActiveCN106927090ABreak the monopolyAnti-corrosive paintsPackaging automatic controlFiberLogistics management

The invention relates to a full-automatic intelligent packaging system for a chemical fiber DTY spindle. A spindle logistics system comprises a spindle storage track and serpentine tracks; an intelligent detection classification system is mounted between the spindle storage track and the serpentine tracks; an intelligent temporary storage system is arranged next to the serpentine tracks; an automatic stacking system is arranged at the tail sections of the serpentine tracks; an automatic unpacking system is arranged in the position, between the intelligent temporary storage system and the automatic stacking system, on the serpentine tracks; and an automatic bagging packing system is arranged at the tail end of the automatic stacking system. According to the full-automatic intelligent packaging system, the bottleneck problems, restraining the sustainable development of Chinese chemical fiber enterprises, that enterprise labor is intensive, the production efficiency is low, the stability of the product quality is poor, and the production management level of workshops is low are effectively solved, the monopoly position of foreign manufacturers in the field of chemical fiber advanced manufacturing equipment in China is broken, and positive demonstration and leading functions are achieved on equipment innovation and transformation upgrading of the chemical fiber industry in China.

Owner:福建百宏聚纤科技实业有限公司

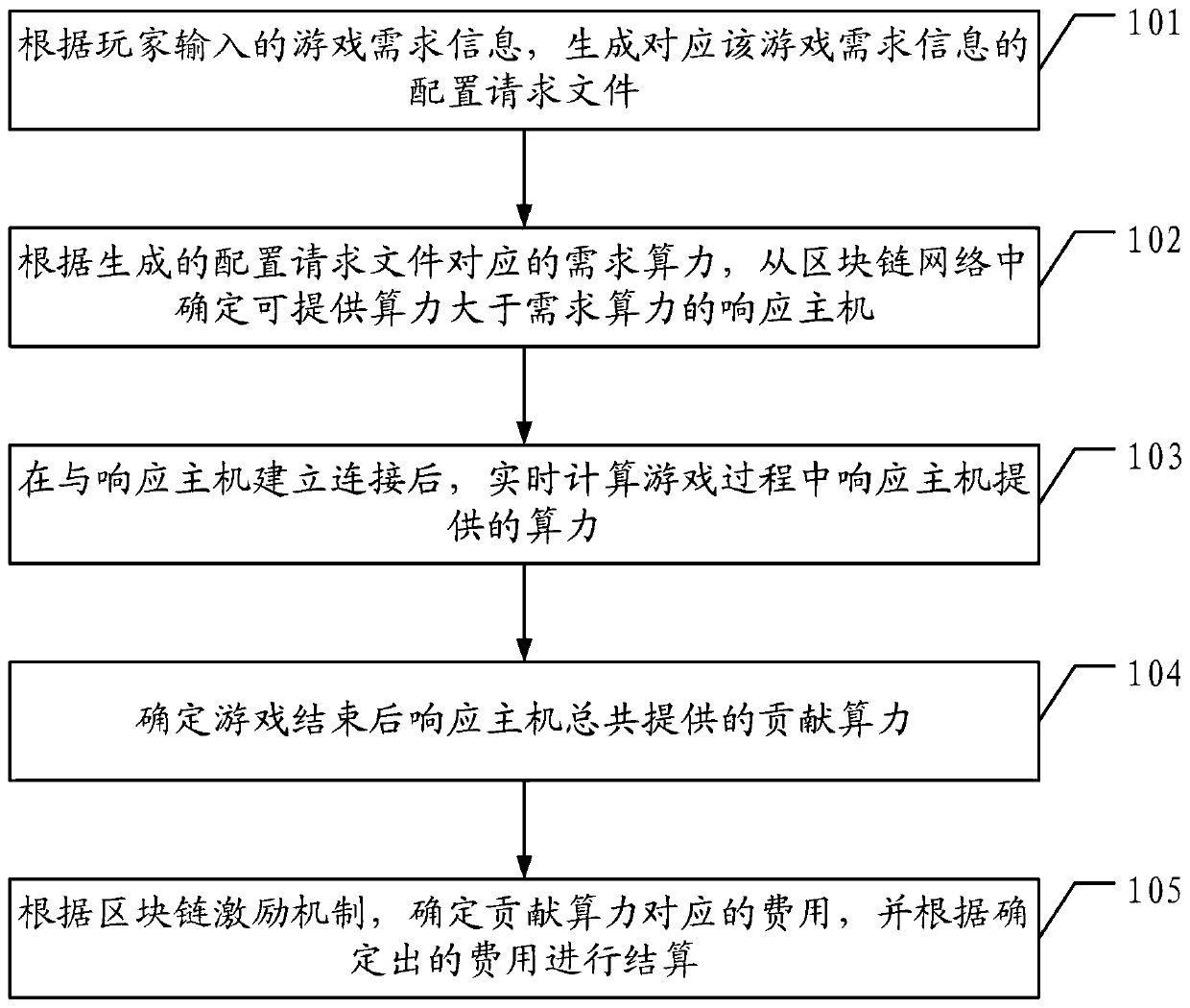

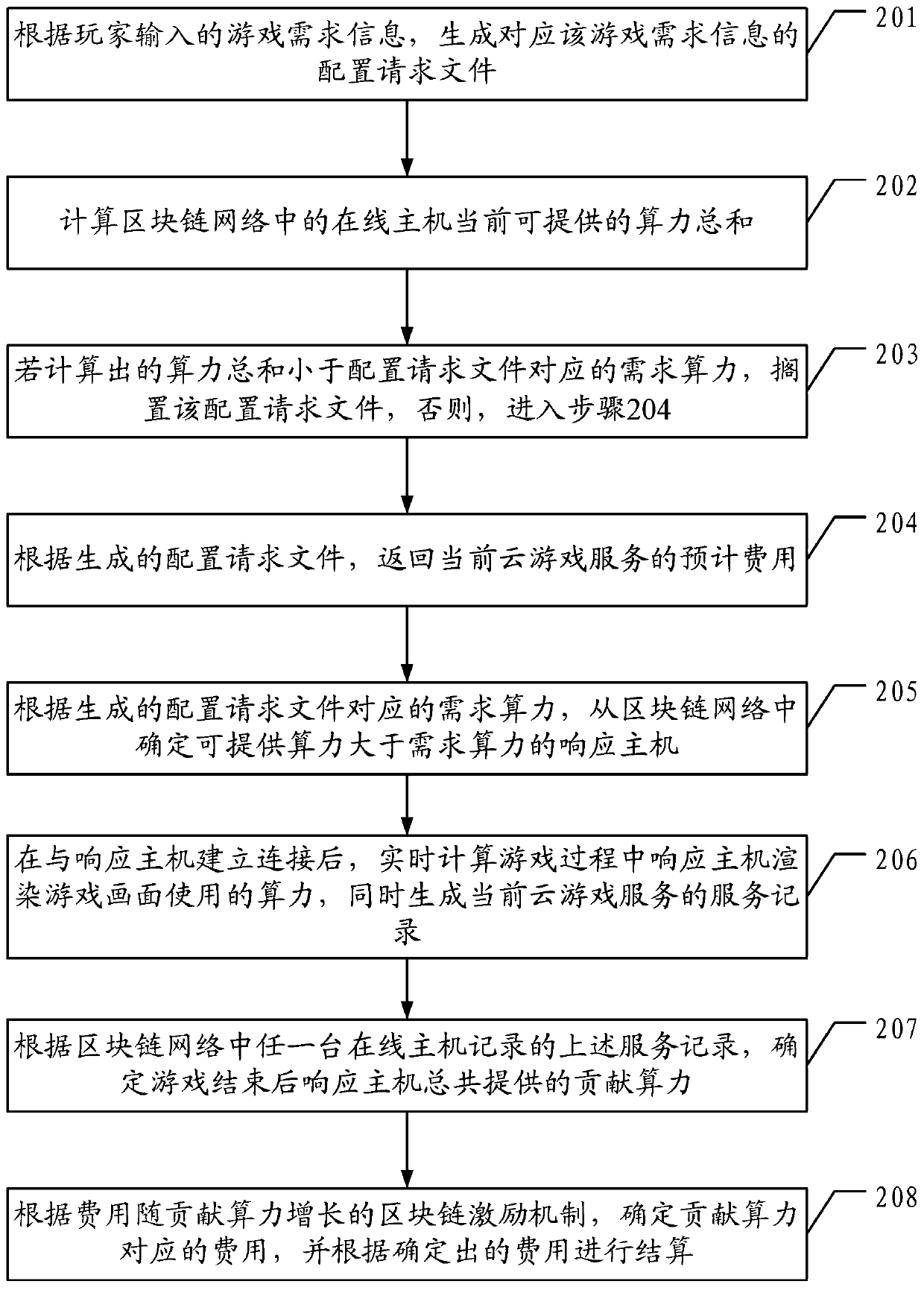

Cloud game method and device

ActiveCN109847341AJoin attractionBreak the monopolyVideo gamesTransmissionChain networkDistributed computing

The embodiment of the invention discloses a cloud game method. The method includes the steps of generating a configuration request file corresponding to game requirement information according to the game requirement information input by a player, determining a response host capable of providing computing power higher than the required computing power in a block chain network according to the required computing power corresponding to the configuration request file, calculating the computing power provided by the response host in the game process in real time, determining the total contributioncomputing power provided by the response hose after a game ends, determining the expense corresponding to the contribution computing power according to a block chain exciting mechanism, and closing anaccount according to the expense. By means of the cloud game method and device, and the technical problems that existing cloud game service is monopolized by a small number of enterprises, cloud gameexpense is too high and the cloud game service is difficult to popularize are solved.

Owner:GUANGDONG UNIV OF TECH

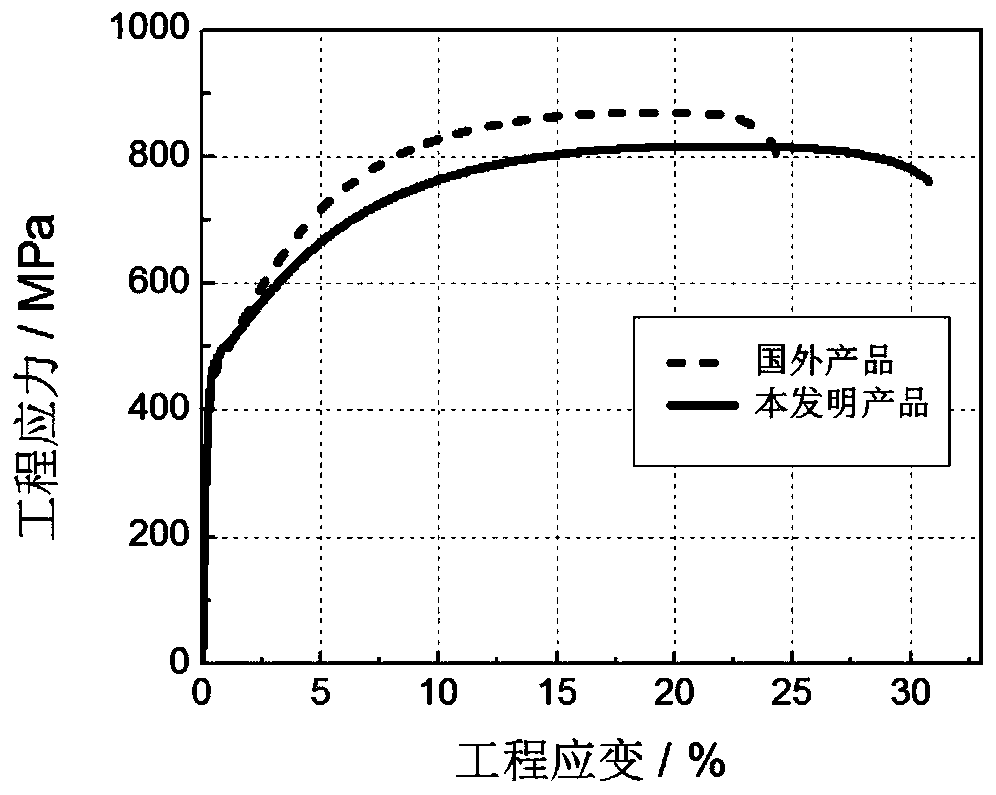

800 MPa grade single side-electrogalvanized phase-change induced plastic steel sheet and preparation method thereof

The invention discloses an 800 MPa grade single side-electrogalvanized phase-change induced plastic steel sheet and a preparation method thereof. The steel sheet comprises strip steel and an electrogalvanized layer formed on one surface of the strip steel, and the thickness of the electrogalvanized layer is 70-90 g / m<2>; and the strip steel comprises the following chemical components of, in percentage by weight, 0.12-0.24% of C, 0.80-1.80% of Si, 1.20-2.50% of Mn, 0.01-0.06% of Nb, less than or equal to 0.20% of P, less than or equal to 0.03% of S, less than or equal to 0.50% of Al, and the balance Fe and inevitable impurities. The steel sheet is better in surface quality and has excellent comprehensive mechanical properties of high strength and high plasticity.

Owner:BENGANG STEEL PLATES

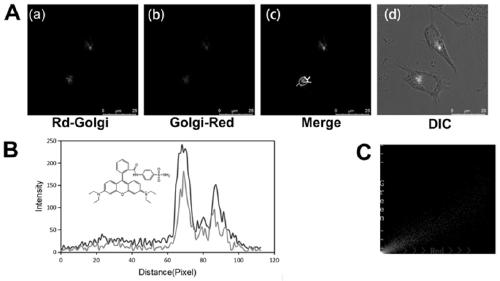

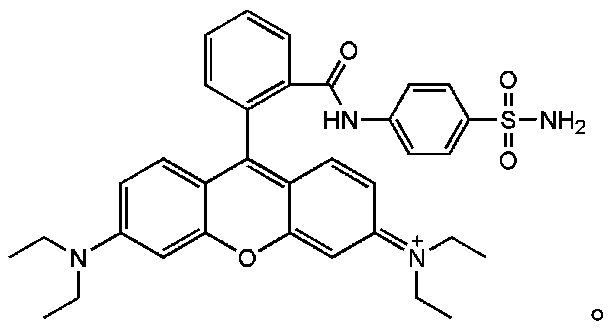

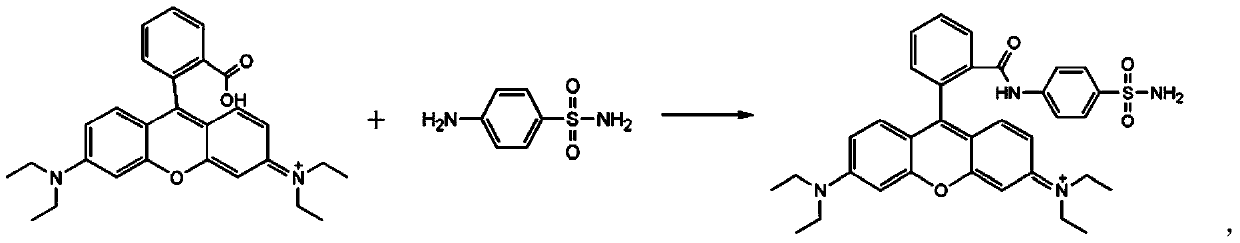

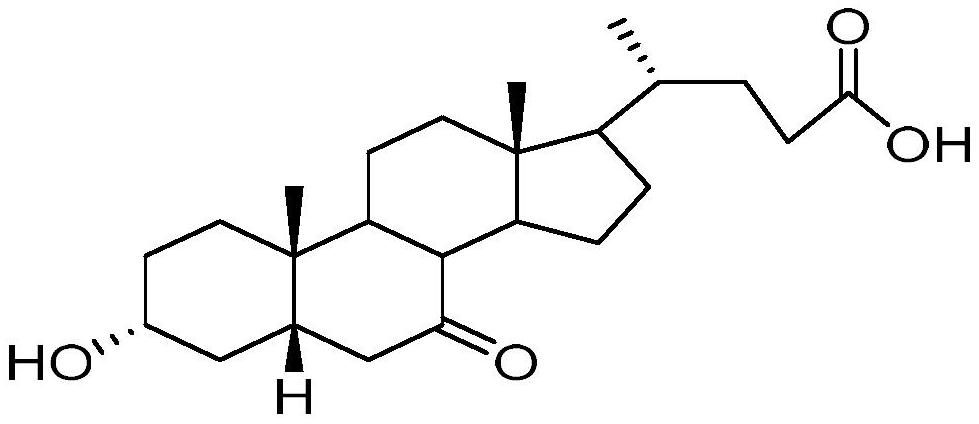

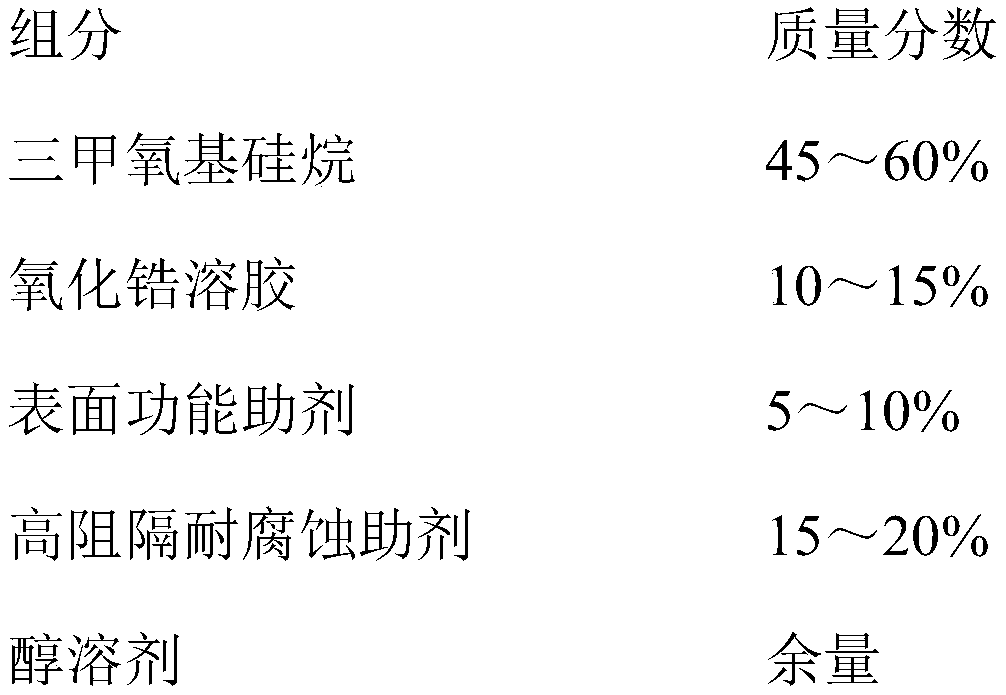

Compound represented by formula (I), and preparation method and application thereof

ActiveCN110386913ASolve the problem of targetingUniversalOrganic chemistryPreparing sample for investigationCombinatorial chemistryStructural formula

The invention discloses a compound represented by a formula (I), and a preparation method and application thereof. The compound represented by formula (I) has the following structural formula. The compound has an excellent Golgi apparatus targeting positioning effect when being used as a dye.

Owner:SHANDONG NORMAL UNIV

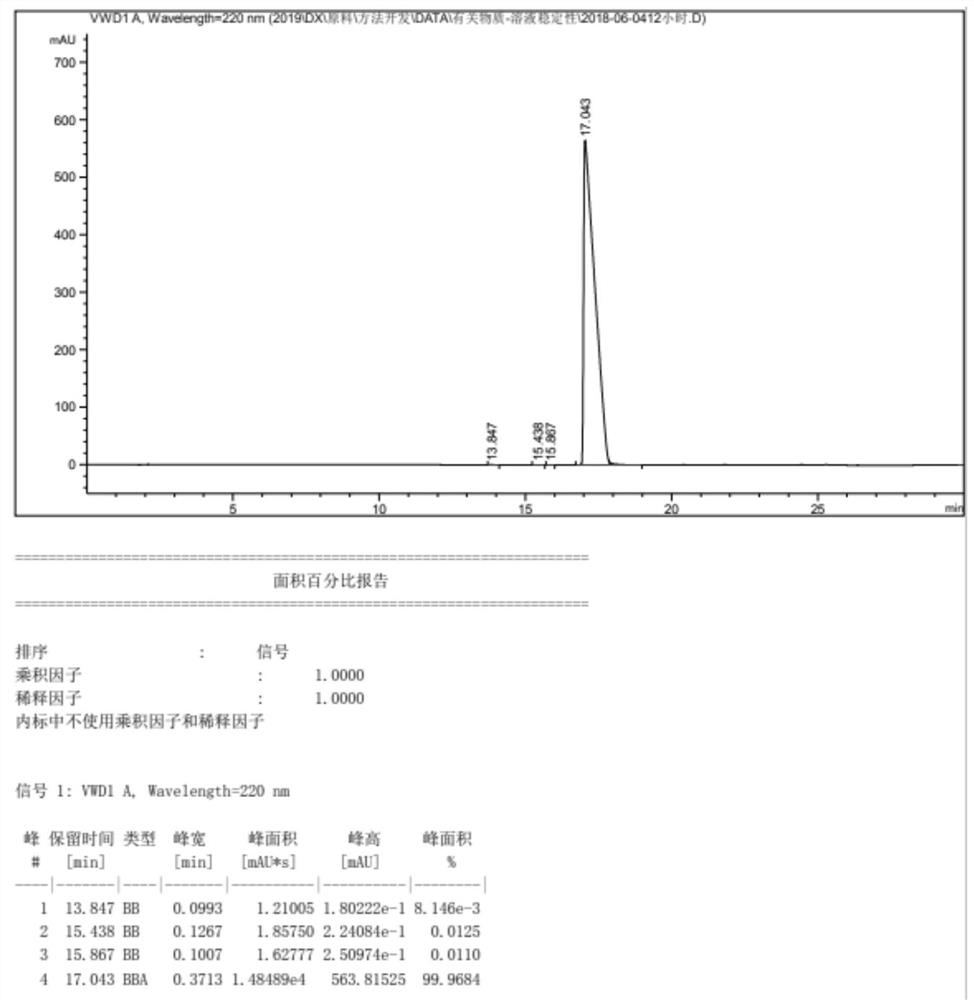

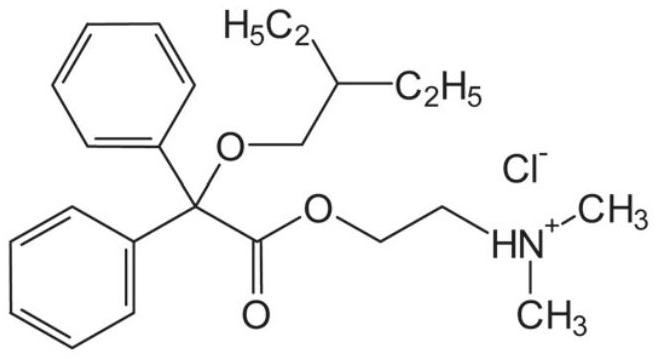

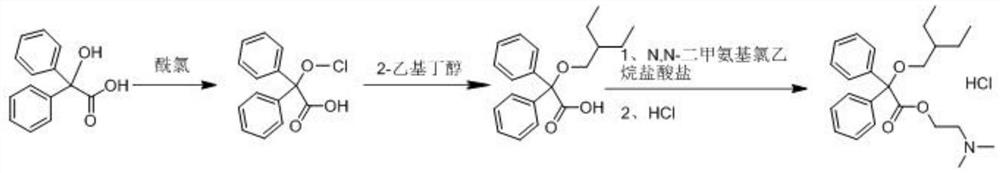

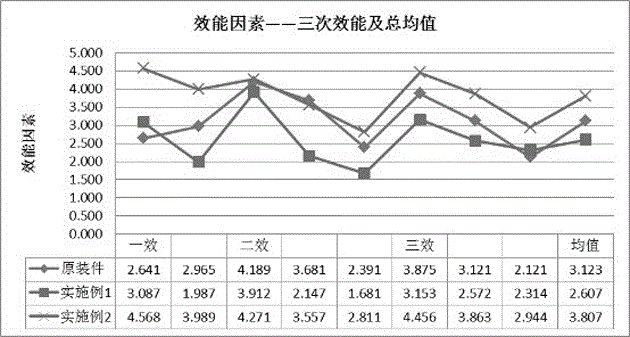

Synthesis method of dinaverine hydrochloride

ActiveCN113061095AHigh yieldHigh purityOrganic compound preparationCarboxylic compound preparationEthyl groupEthyl acetate

The invention provides a synthesis method of dinaverine hydrochloride. The method comprises the following steps: S1, reacting 2, 2-diphenyl-2-glycolic acid with acyl chloride, and then adding 2-ethyl butanol and alkali for reaction to obtain an intermediate 2-(2-ethyl butoxy)-2, 2-diphenylacetic acid; s2, adding alkali and N, N-dimethylaminochloroethane hydrochloride into the intermediate for a reaction, then introducing hydrogen chloride gas for a period of time, carrying out concentration, adding ethyl acetate, filtering, and obtaining denaverine hydrochloride.

Owner:NINGBO SANSHENG BIOLOGICAL TECH CO LTD

Friction material for drum brake of nine-seat passenger vehicle and preparation method of drum brake block

InactiveCN105570359ASimple materialEasy to prepareOther chemical processesBraking membersDrum brakeEngineering

Owner:ZHUHAI HUALI FRICTION MATERIAL +1

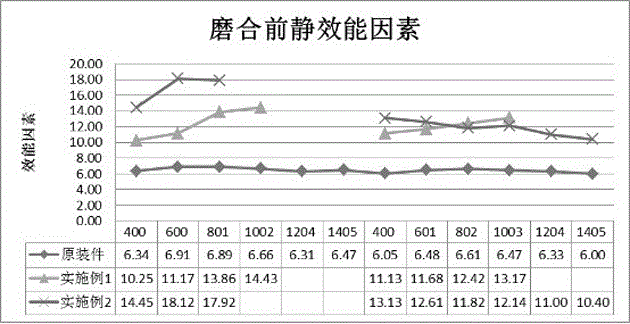

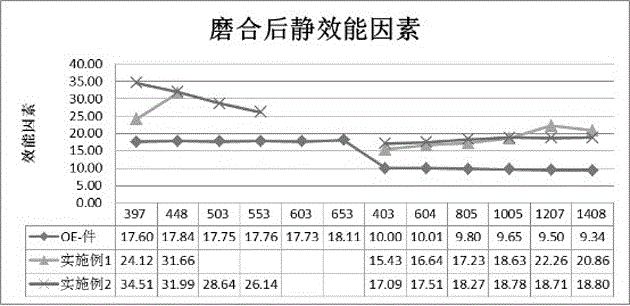

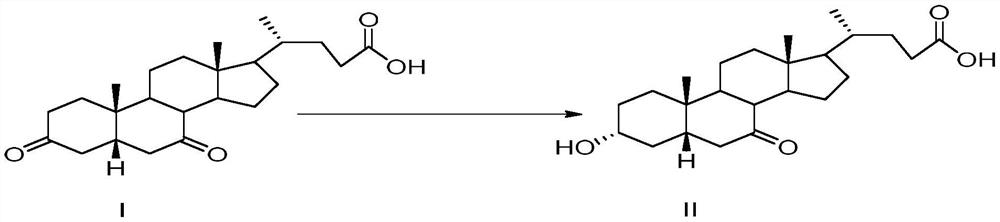

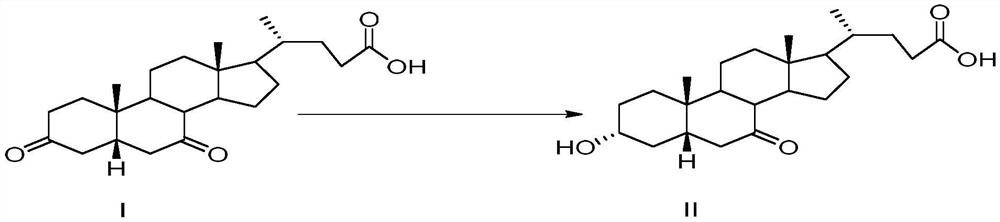

Preparation method of plant-derived 7-ketolithocholic acid

ActiveCN113968891ABreak the monopolyWide variety of sourcesSteroidsBulk chemical productionBiotechnologyCholic acid

The invention provides a preparation method of plant-derived 7-ketolithocholic acid, which comprises the following steps: by taking 3,7-diketone-5beta-cholestane-24-acid shown in a formula I as a raw material, reacting in 3 alpha reductase and a system containing alkaline water to generate the 7-ketolithocholic acid shown in a formula II. According to the invention, 3,7-diketone-5beta-cholestane-24-acid prepared from a plant source fermentation product BA through a series of synthesis is taken as a starting material, so that a plant source total synthesis route is opened, and monopoly of animal sources is broken. The starting raw materials are wide in source, and the possibility of carrying animal source genetic viruses is avoided. According to the method, the 3alpha reductase is used, the characteristic of high specificity of the enzyme is utilized, the selective reduction effect is good, and no 3beta hydroxyl isomer exists; meanwhile, the process is safe and environmentally friendly through reaction of alkaline water and the glycerin / 2-methyltetrahydrofuran system, and the compound II is high in yield and good in purity.

Owner:HUNAN KEREY BIOTECH

A kind of pure nickel tube for chemical equipment falling film and preparation method thereof

The invention relates to a pure-nickel tube for a chemical equipment falling film and a preparation method of the pure-nickel tube, and belongs to the field of nickel-chromium smelting and common nonferrous metal rolling. The pure-nickel tube is prepared from, by mass percentage, larger than or equal to 99.0% of Ni+Co and 0.05%-0.60% of Ti in the formula, wherein impurity elements are controlled to the situation that the percentage of Cu is smaller than or equal to 0.015%, the percentage of Si is smaller than or equal to 0.03% of Si, the percentage of Mn is smaller than or equal to 0.002%, andthe percentage of Mg is smaller than or equal to 0.01%. The pure-nickel tube is prepared through vacuum melting, electroslag remelting, forging, cross piercing, tube blank coping, combined rolling, inner hole coping and annealing. By the adoption of the formula and the process, the harmful impurity elements such as C, S and P of the pure-nickel tube for the falling film can be effectively controlled within a low limit, meanwhile, Ti is added, the strength of the nickel tube is enhanced, and the deformation resistance of the nickel tube under the working environment condition is greatly improved. Through control over the components and the machining process, the yield of products is increased, the production cost is reduced, the content of inclusions and other harmful matter is reduced, the strength and the extension property are obviously improved, and the service life of the nickel tube during use is prolonged.

Owner:江苏隆达超合金股份有限公司

Chemical fiber dty spindle automatic intelligent packaging system

ActiveCN106927090BBreak the monopolyAnti-corrosive paintsPackaging automatic controlFiberLogistics management

The invention relates to a full-automatic intelligent packaging system for a chemical fiber DTY spindle. A spindle logistics system comprises a spindle storage track and serpentine tracks; an intelligent detection classification system is mounted between the spindle storage track and the serpentine tracks; an intelligent temporary storage system is arranged next to the serpentine tracks; an automatic stacking system is arranged at the tail sections of the serpentine tracks; an automatic unpacking system is arranged in the position, between the intelligent temporary storage system and the automatic stacking system, on the serpentine tracks; and an automatic bagging packing system is arranged at the tail end of the automatic stacking system. According to the full-automatic intelligent packaging system, the bottleneck problems, restraining the sustainable development of Chinese chemical fiber enterprises, that enterprise labor is intensive, the production efficiency is low, the stability of the product quality is poor, and the production management level of workshops is low are effectively solved, the monopoly position of foreign manufacturers in the field of chemical fiber advanced manufacturing equipment in China is broken, and positive demonstration and leading functions are achieved on equipment innovation and transformation upgrading of the chemical fiber industry in China.

Owner:福建百宏聚纤科技实业有限公司

Small tyre repairing vulcanizing machine

The invention discloses a small tyre repairing vulcanizing machine which comprises a worktable, a fixed vertical plate and an external pressure plate, wherein the fixed vertical plate is arranged at one side of the worktable, the external pressure plate is articulated at the other side of the worktable, the upper part of the external pressure plate is connected with the fixed vertical plate through a connecting piece, an internal pressure plate is articulated at the upper end of the fixed vertical plate, and the upper part of the external pressure plate is higher than the upper part of the internal pressure plate; and a pressing gasbag and a heating vulcanizing plate are arranged along the plane of the worktable and the lower surface of the internal pressure plate. The small tyre repairing vulcanizing machine has simple structure, convenient operation, lower cost and wide application range, can repair small openings and large openings on all car tyres and has low repairing cost and good repairing quality.

Owner:洪林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com