Polypropylene material for stretched film and preparation method of polypropylene material

A technology of polypropylene material and polypropylene resin, which is applied in the field of polypropylene material and its preparation, can solve the problem of high price and achieve the effects of high stiffness and transparency, stable quality and high flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

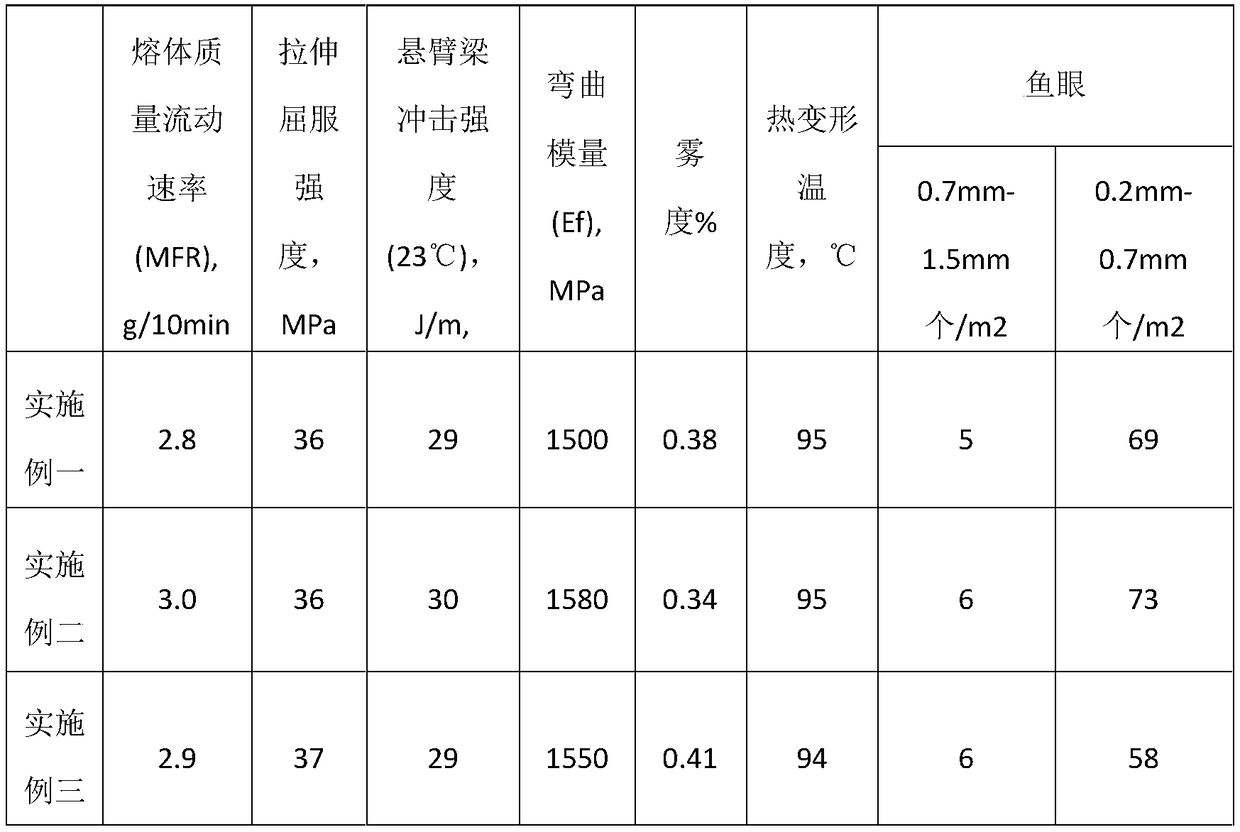

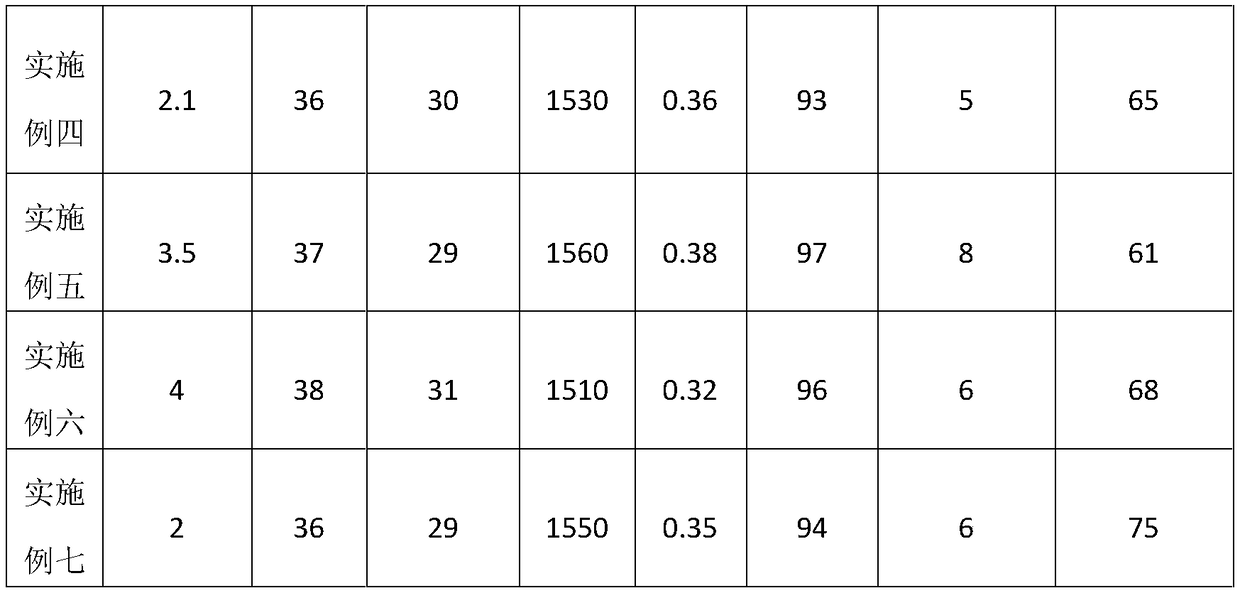

Examples

Embodiment 1

[0030] (1) Using the Sphripol polymerization process, propylene is pre-polymerized under the joint action of the main catalyst, co-catalyst and external electron donor, and then enters a loop pipe. The temperature of the reactor is controlled at 70°C, the hydrogen concentration is 350ppm, and the ethylene / propylene is 4kg / t, and the preparation obtains polypropylene powder;

[0031] (2) The polypropylene powder obtained in step (1) enters the two-loop pipe together with propylene and hydrogen, the temperature of the reactor is controlled at 70° C., and the hydrogen concentration is 1050 ppm to prepare the polypropylene resin powder;

[0032] (3) Mix the polypropylene resin powder obtained in step (2) with the auxiliary agent according to the following proportions: polypropylene resin powder: 99.6 parts, antioxidant 1010: 0.1 part, auxiliary antioxidant U626: 0.05 part, Halogen absorbent: 0.05 parts, α nucleating agent: 0.2 parts;

[0033] (4) Extrude the mixture obtained in ...

Embodiment 2

[0036] (1) Using the Sphripol polymerization process, propylene is pre-polymerized under the joint action of the main catalyst, co-catalyst and external electron donor, and then enters a loop pipe. The temperature of the reactor is controlled at 70 °C, the hydrogen concentration is 400ppm, and the ethylene / propylene is 4.5kg / t, and the preparation obtains polypropylene powder;

[0037] (2) The polypropylene powder obtained in step (1) enters the second ring pipe together with propylene and hydrogen, the temperature of the reactor is controlled at 70° C., and the hydrogen concentration is 1000 ppm to prepare polypropylene resin powder;

[0038] (3) Mix the polypropylene resin powder obtained in step (2) with the auxiliary agent according to the following proportions: polypropylene resin powder: 99.55 parts, antioxidant 1010: 0.09 part, auxiliary antioxidant U626: 0.06 part, Halogen absorbent: 0.05 parts, α nucleating agent: 0.25 parts;

[0039] (4) Extrude the mixture obtaine...

Embodiment 3

[0042] (1) Using the Sphripol polymerization process, propylene is pre-polymerized under the joint action of the main catalyst, co-catalyst and external electron donor, and then enters a loop pipe. The temperature of the reactor is controlled at 70 °C, the hydrogen concentration is 450ppm, and the ethylene / propylene is 4.2kg / t, and the polypropylene powder is prepared;

[0043] (2) The polypropylene powder obtained in step (1) enters the two-loop pipe together with propylene and hydrogen, the temperature of the reactor is controlled at 70°C, and the hydrogen concentration is 950ppm to prepare the polypropylene resin powder;

[0044] (3) Mix the polypropylene resin powder obtained in step (2) with the auxiliary agent according to the following proportions: polypropylene resin powder: 99.58 parts, antioxidant 1010: 0.12 parts, auxiliary antioxidant U626: 0.06 parts, Halogen absorbent: 0.06 parts, α-nucleating agent: 0.18 parts;

[0045] (4) Extrude the mixture obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com