Full-automatic intelligent packaging system for chemical fiber DTY spindle

A smart packaging and fully automatic technology, applied in packaging, packaging machines, packaging protection, etc., can solve problems such as overcapacity, difficulties in survival and development, and lagging behind in the development of production and service industries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

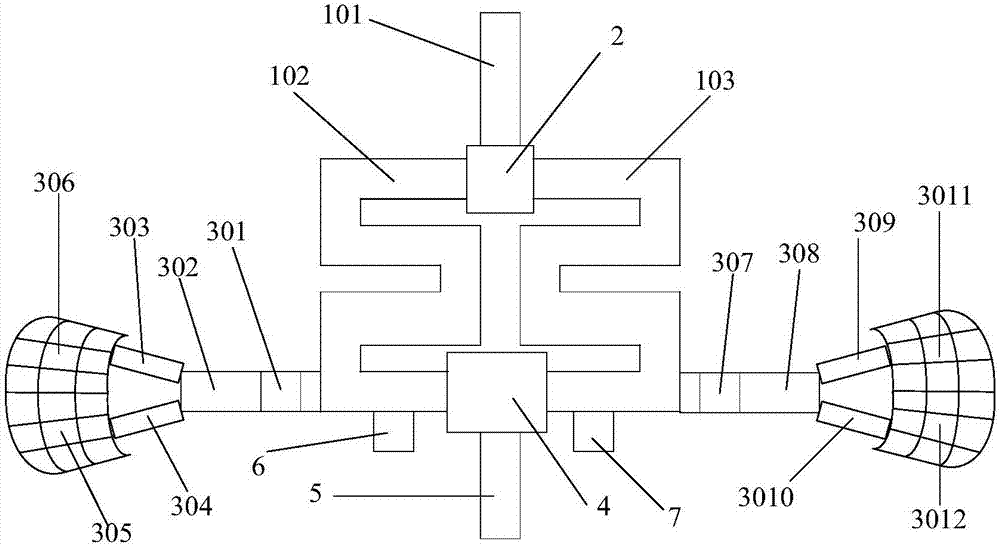

[0068] Please see attached figure 1 , a fully automatic intelligent packaging system for chemical fiber DTY spindles, which includes a spindle logistics system, an intelligent inspection and classification system 2, an intelligent temporary storage system, an automatic palletizing system 4, an automatic bagging and packing system 5, an automatic unpacking system and computer management center; the spindle logistics system includes a spindle storage track 101 and a serpentine track, an intelligent detection and classification system 2 is installed between the spindle storage track and the serpentine track, and the intelligent temporary storage system is set next to the serpentine track, and automatically stacks System 4 is set at the end of the serpentine track, an automatic unpacking system is set on the serpentine track between the intelligent temporary storage system and the automatic palletizing system, and an automatic bagging and boxing system is set at the end of the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com