Ferritic stainless steel and manufacturing process thereof

A manufacturing process, stainless steel technology, applied in the field of ferritic stainless steel and its manufacturing process, can solve the problems of restricting development, poor corrosion resistance, high price, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A ferritic stainless steel, including Fe element and modifying chemical elements, the weight percentage of each chemical element is shown in Table 1:

[0034] Table 1 Each chemical element and its weight percentage

[0035] the element

mass percentage

C

0.010%

Si

0

mn

0.012%

P

0.025%

S

0.003%

Cr

17.02%

Ni

0.40%

Mo

0.02%

Cu

0.06%

Al

0.020%

Ti

0.35%

N

0.01%

Fe

82.07%

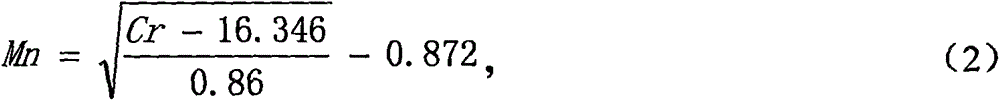

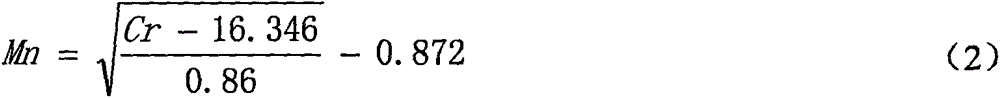

[0036] Wherein the weight percentage of Mo is 0.02%, the weight percentage of Mn obtained by formula (1) is 0.012%, and the weight percentage of Cr obtained by formula (2) is 17.02%.

[0037] According to the formula (3) 0.20%+4(C+N)%≤Ti≤0.50%, in this embodiment, 0.20%+4(C+N)%=0.28%, so Ti in this embodiment is 0.35% Meet the conditions of formula (3).

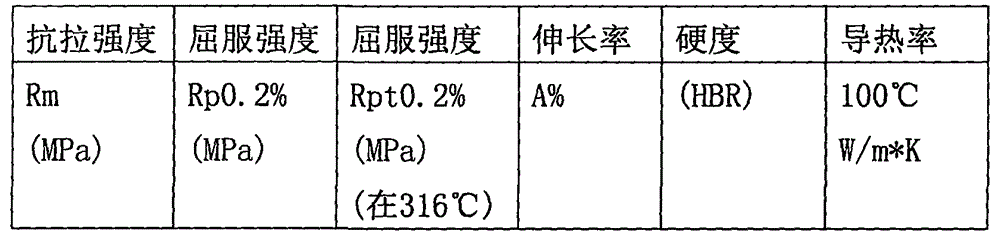

[0038] The present embodiment contains the mechanical property test result of the ferritic ...

Embodiment 2

[0045] A ferritic stainless steel, including Fe element and modified chemical elements, the weight percentage of each chemical element is shown in Table 3:

[0046] Table 3 each chemical element and its weight percentage

[0047] the element

mass percentage

C

0.020%

Si

0.55%

mn

0.80%

P

0

S

0.006%

Cr

18.75%

Ni

0

Mo

0.05%

[0048] Cu

0.03%

Al

0.040%

Ti

0.50%

N

0.02%

Fe

79.234%

[0049] Wherein the weight percentage of Mo is 0.05%, the weight percentage of Mn obtained by formula (1) is 0.80%, and the weight percentage of Cr obtained by formula (2) is 18.75%.

[0050] According to formula (3) 0.20%+4(C+N)%≤Ti≤0.50%, in this embodiment, 0.20%+4(C+N)%=0.36%, so Ti in this embodiment is 0.50% Meet the conditions of formula (3).

[0051]The present embodiment contains the mechanical performance test result of the...

Embodiment 3

[0056] A ferritic stainless steel, including Fe element and modified chemical elements, the weight percentage of each chemical element is shown in Table 5:

[0057] Table 5 elements and their weight percentages

[0058] the element

mass percentage

C

0

Si

0.35%

mn

0

P

0.02%

S

0.001%

Cr

17.00%

Ni

0.20%

Mo

0

Cu

0.01%

Al

0.010%

Ti

0.26%

N

0.015%

Fe

82.134%

[0059] Wherein the weight percentage of Mo is 0, the weight percentage of Mn is 0 obtained by the formula (1), and the weight percentage of Cr is 17.00% by the formula (2).

[0060] According to formula (3) 0.20%+4(C+N)%≤Ti≤0.50%, in this embodiment, 0.20%+4(C+N)%=0.26%, so Ti in this embodiment is 0.26% Meet the conditions of formula (3).

[0061] The present embodiment contains the mechanical property test result of the ferritic stainless steel of above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com