Cigarette dense end position dead-point-free correction device

A technology of correction device and no dead point, which is applied in the direction of transmission, tobacco, and cigarette manufacturing, etc., can solve the problems of low correction response rate, prone to dead point, phase lag, etc., and achieve convenient on-site improvement, stable and controllable transmission, The effect of small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

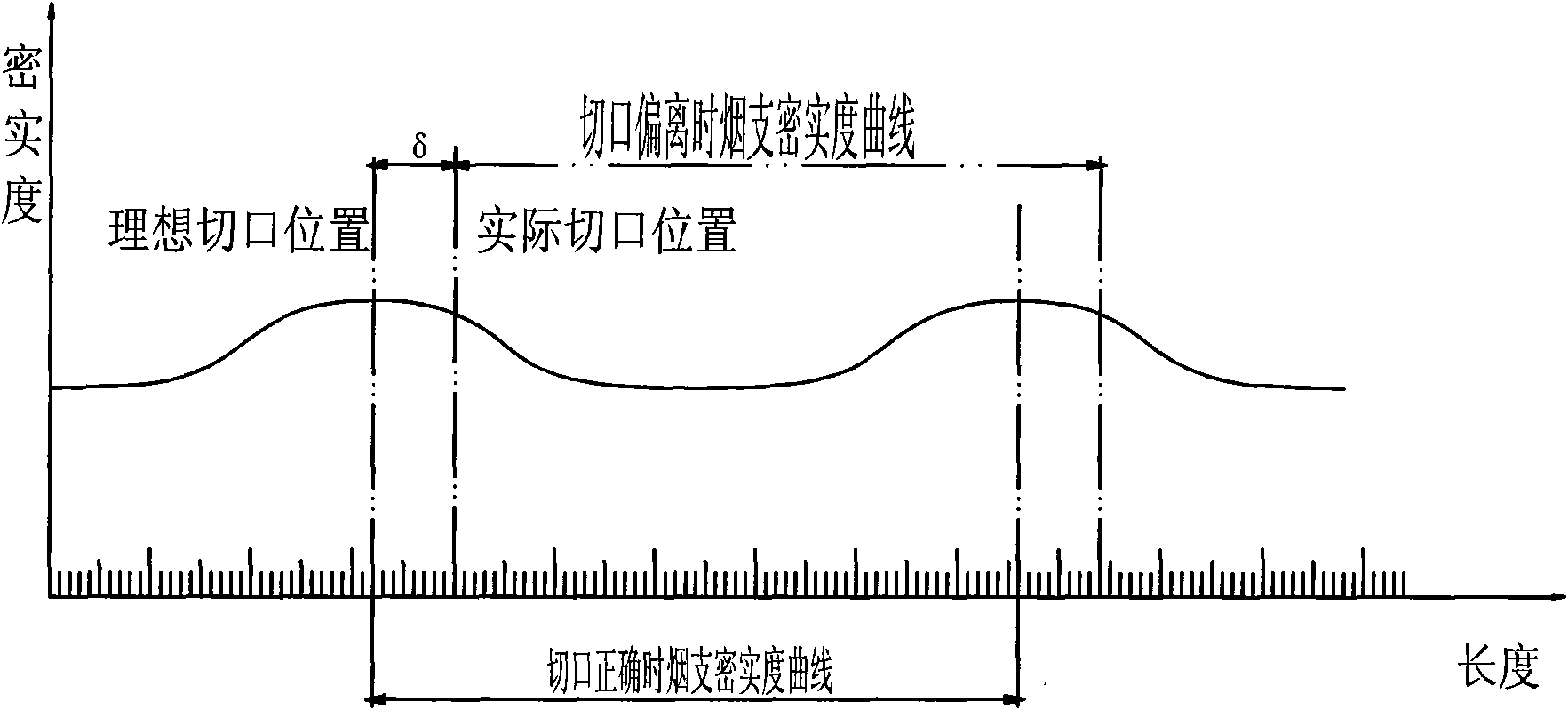

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

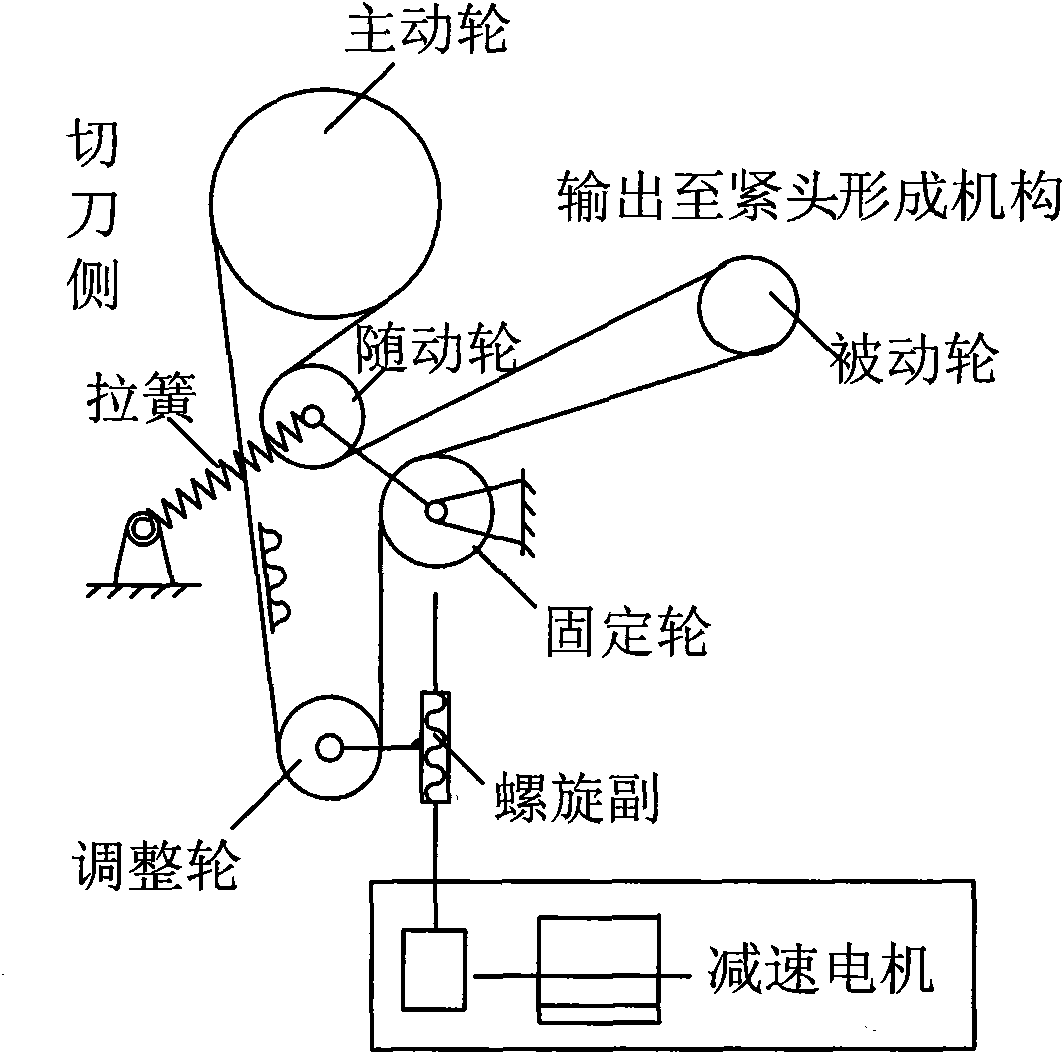

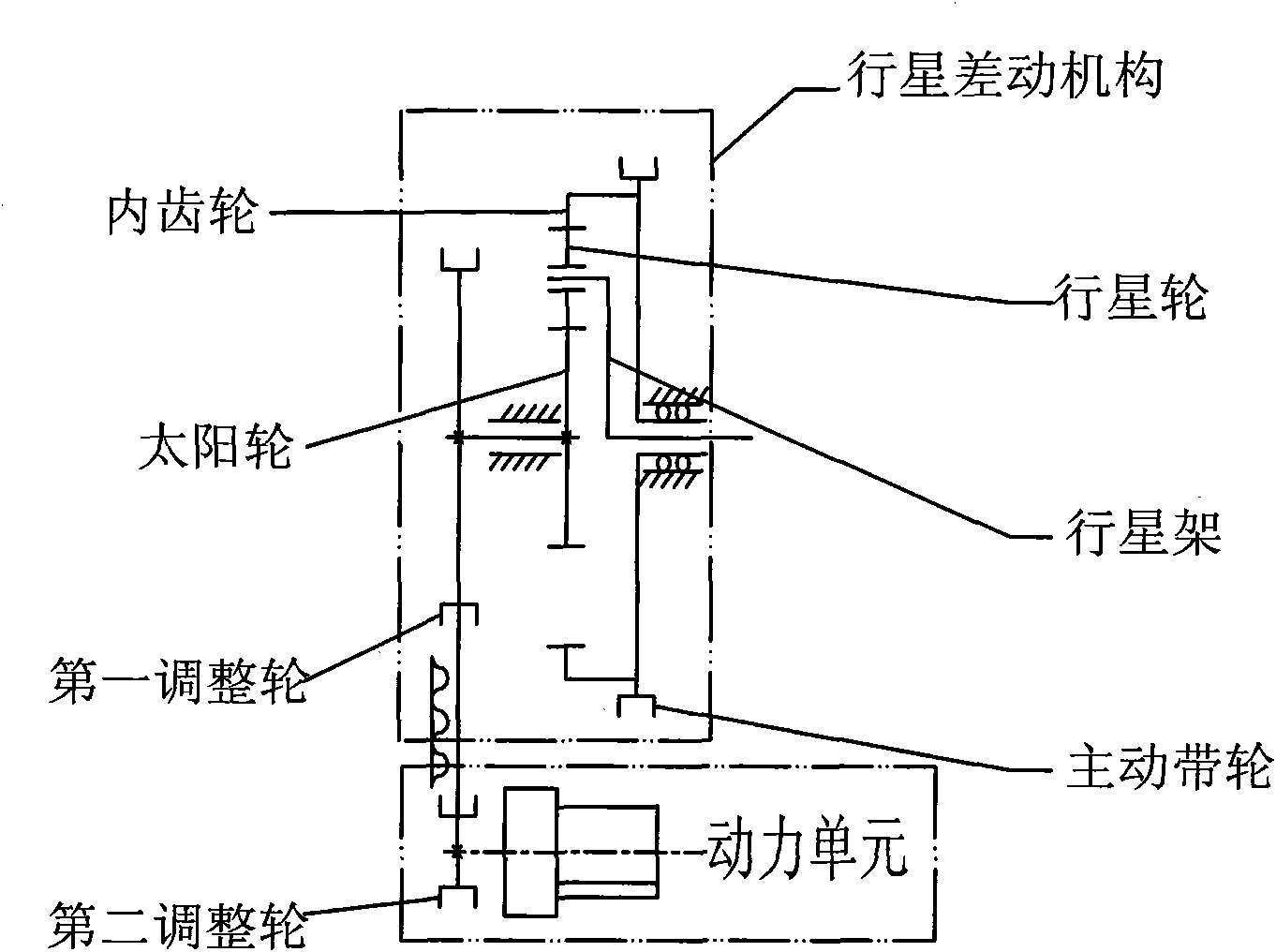

[0019] Such as image 3 and Figure 4 As shown, the non-dead point correction device for the tight head position of cigarettes of the present invention includes an internal gear, a sun gear, a first adjustment wheel, a second adjustment wheel, a planetary carrier, a planetary wheel, a driving pulley, a tensioning wheel, a driven wheel and a power The inner gear, the sun gear, the first adjustment wheel, the planetary carrier, the planetary wheel and the driving pulley form a planetary differential mechanism, the sun gear is the fixed axis of the planetary gear differential mechanism, and the sun gear is fixedly connected with the first adjustment wheel , the first adjustment wheel and the second adjustment wheel are connected through the timing belt, the second adjustment wheel is connected with the power u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com