Low-cost titanium alloy welding wire suitable for welding titanium alloy at high temperature of over 520 DEG C

A high-temperature titanium alloy, low-cost technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of reduced toughness, reduced degree of alloying in the weld zone, and material plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail through the following several preferred embodiments, but the present invention is not limited to the following several embodiments.

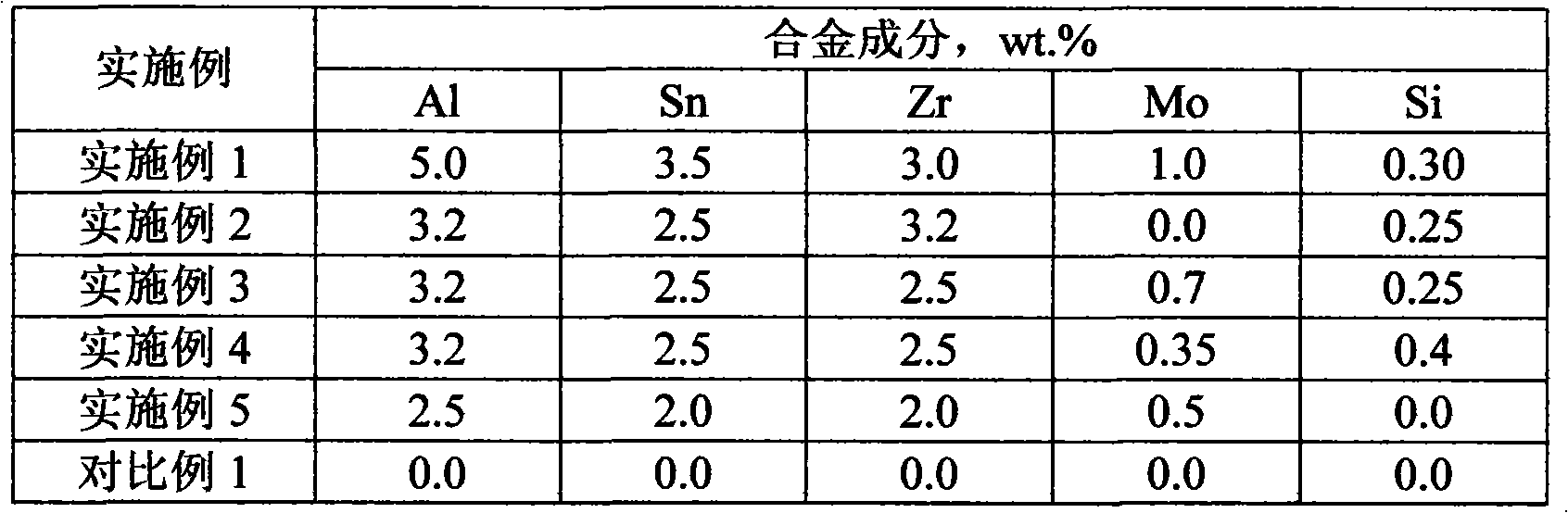

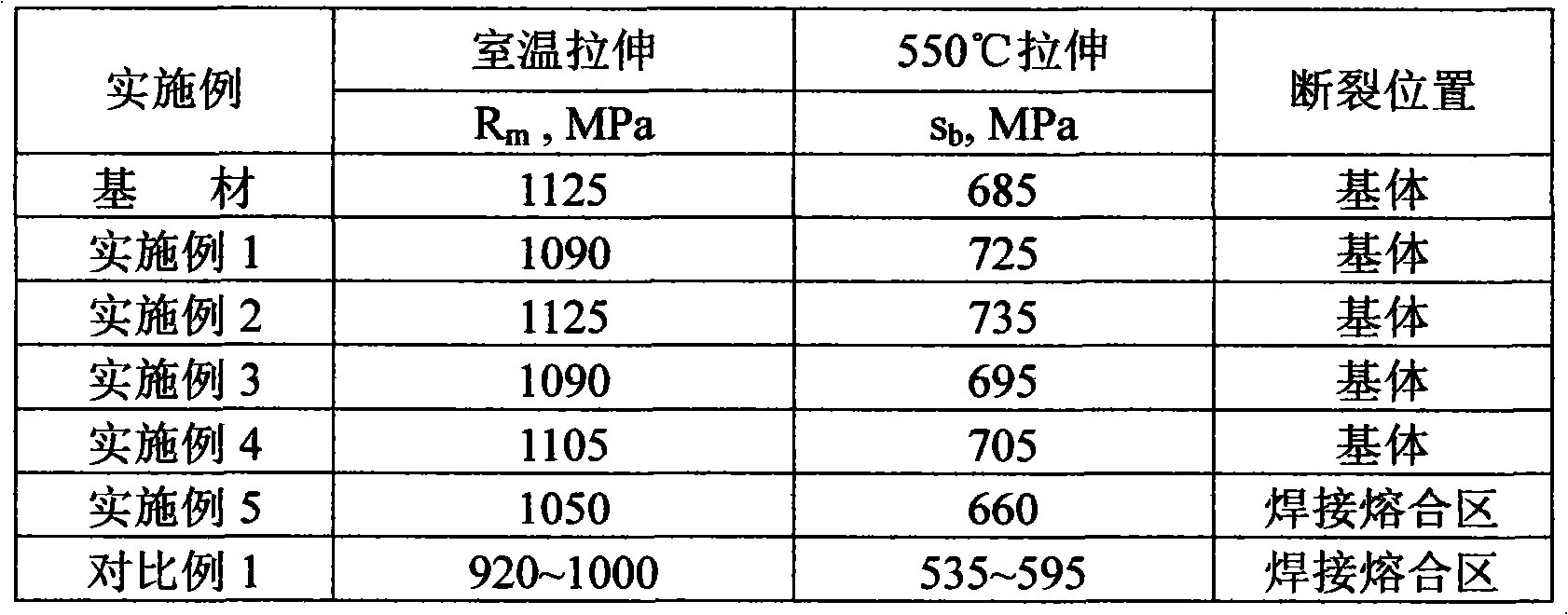

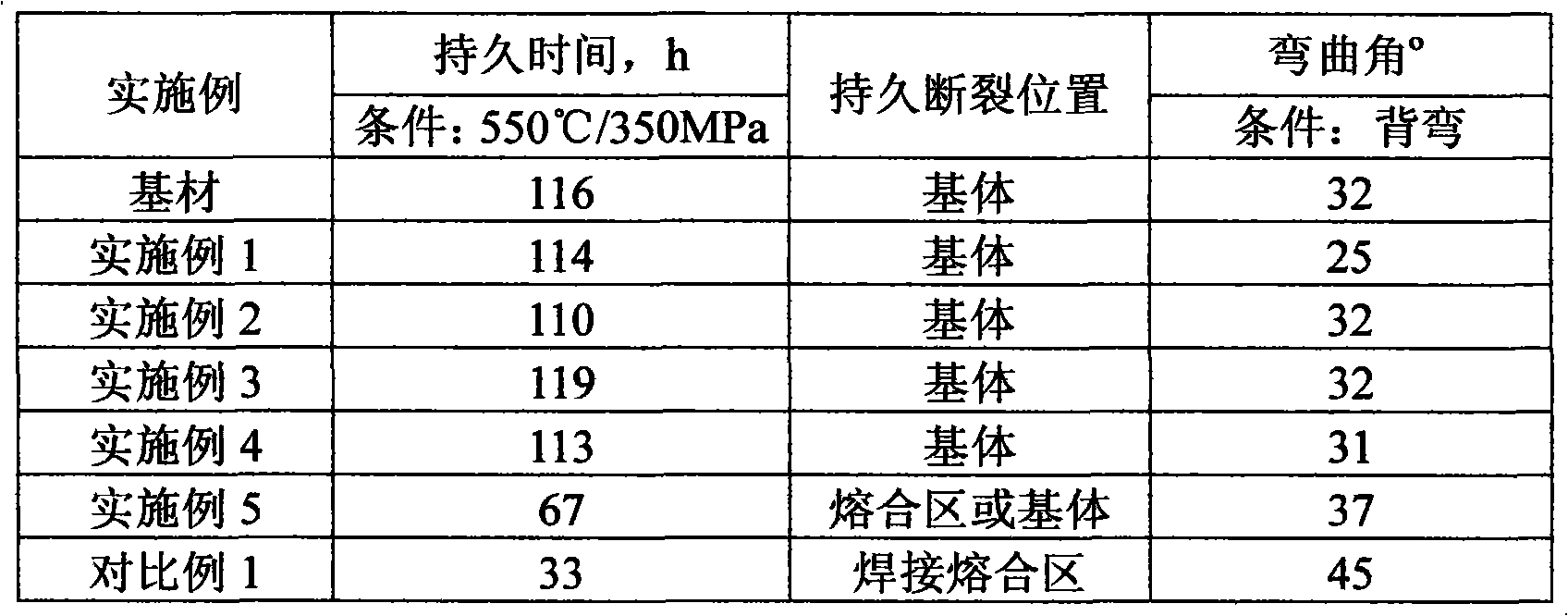

[0019] Table 1

[0020]

[0021] The smelting process of titanium alloy within the composition range of the present invention is as follows: the raw material adopts 0-grade sponge titanium, the alloy element Si is in the form of Al-Si master alloy, Al and Zr are in the form of pure metal, Sn is in the form of TiSn master alloy, and Mo is in the form of Al-Mo master alloy join in. After the master alloy and titanium sponge are batched and mixed, they are pressed into small electrodes with a press. Several small electrode groups are welded together, put into a vacuum consumable electrode electric arc furnace and smelted twice to make an alloy ingot. After the cap is cut off and the surface defects are removed, the ingot enters the thermal processing process. Ingot billeting→hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com