Preparation process of novel grid ring for compact spinning

A preparation process and grid ring technology, applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve problems such as reduced transmission performance of grid rings, changes in grid ring performance, and production cost constraints, and achieve the goal of implementing The effect of smooth process, improved wear resistance and reasonable process arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

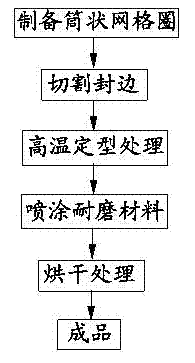

[0017] figure 1 It is a step diagram of the preparation process of the new mesh ring for compact spinning in the embodiment of the present invention; the preparation process mainly includes the following steps: a) preparing a cylindrical mesh ring, b) cutting edge sealing, c) high temperature setting treatment, d) Spraying wear-resistant materials, e) drying treatment.

[0018] The specific operation steps are as follows:

[0019] a) Prepare a cylindrical grid ring, the grid ring is formed by weaving warp and weft on a weaving machine; wherein, the material of the warp is polyester, the material of the weft is nylon 6 or nylon 66, and the warp a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com