Integrated laser anti-counterfeiting package and manufacturing method thereof

A laser anti-counterfeiting and packaging technology, used in identification devices, instruments, coverings/external coatings, etc., can solve the problems of complex processes, no anti-counterfeiting ability in the form of covering, limited laser image layout or pattern, etc., to ensure uniqueness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

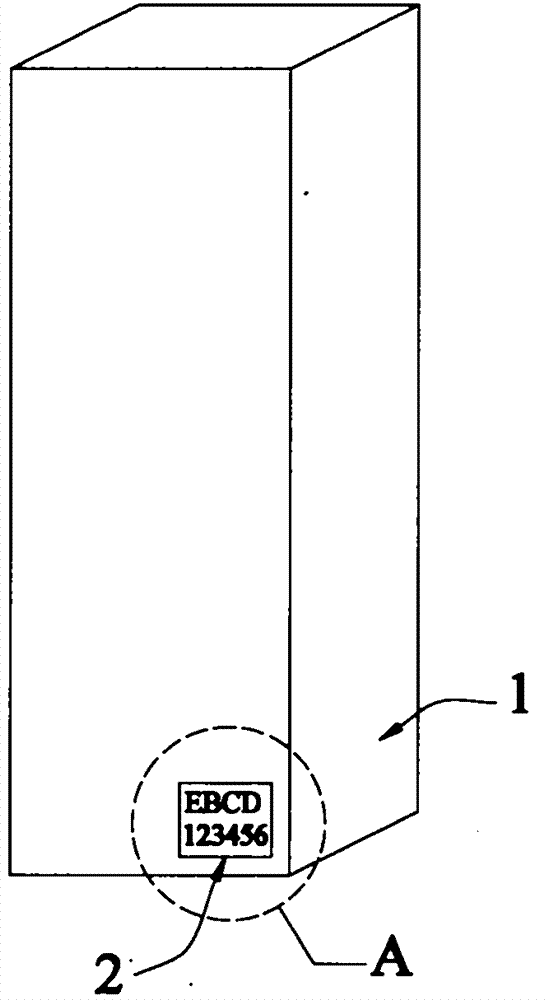

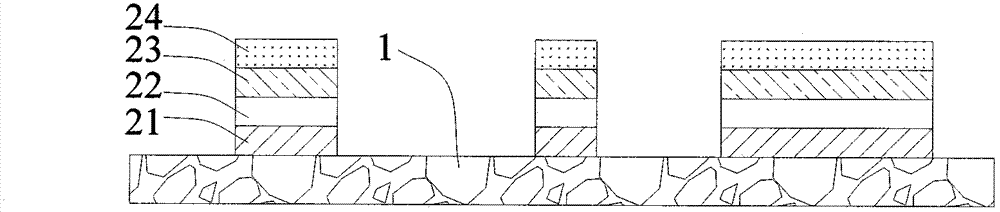

[0019] like figure 1 The integrated laser anti-counterfeiting package shown has a laser anti-counterfeiting label 2 transferred on the outer packaging carrier 1 of the product. to combine figure 2 As shown, the laser anti-counterfeiting label 2 transferred on the outer packaging carrier 1 includes an alkali-resistant ink layer 21, a metal layer 22, a transparent photosensitive material layer 23 and a transparent release material layer 24 from bottom to top, and the alkaline ink layer 21. The metal layer 22, the transparent photosensitive material layer 23 and the transparent release material layer 24 have the same and overlapping hollowed-out patterns, and the number of hollowed out parts is 3.

[0020] Among them, the alkaline ink layer 21 is used to form various different graphics and texts, which can change the anti-counterfeiting mark in time, or complicate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com