Reciprocating rotary frame

A technology of reciprocating rotation and rotating shaft, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency, high labor intensity, difficult handling, etc., achieve simple structure, improve handling speed, save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

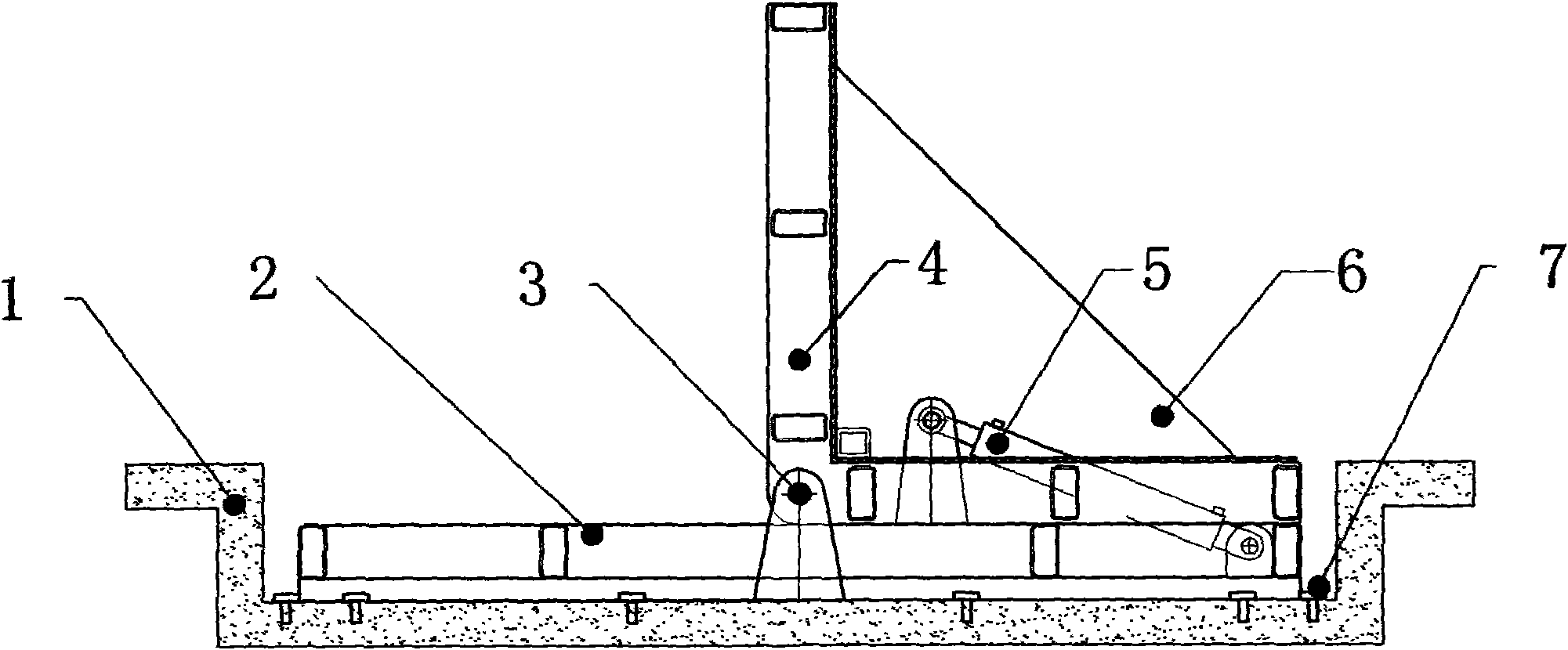

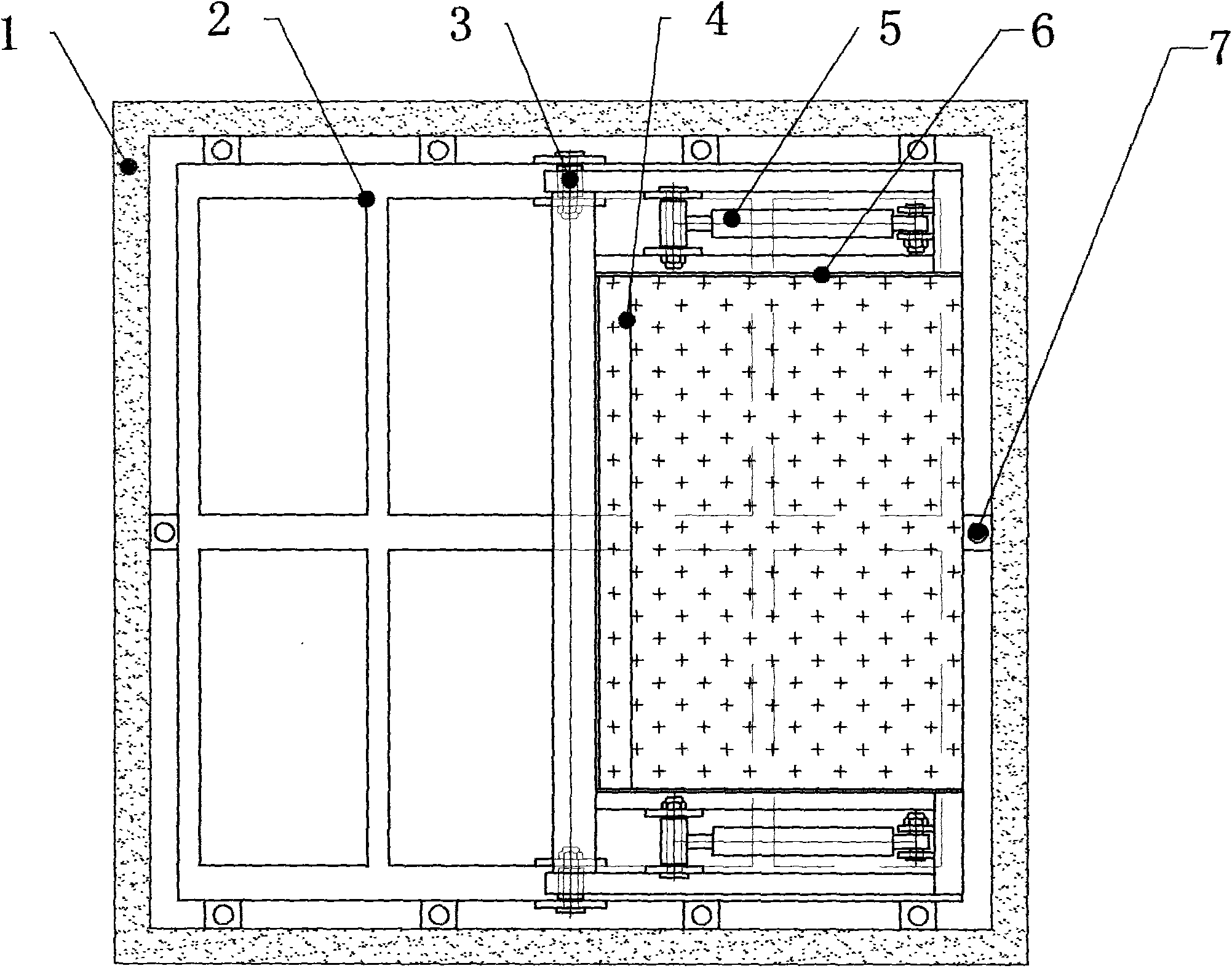

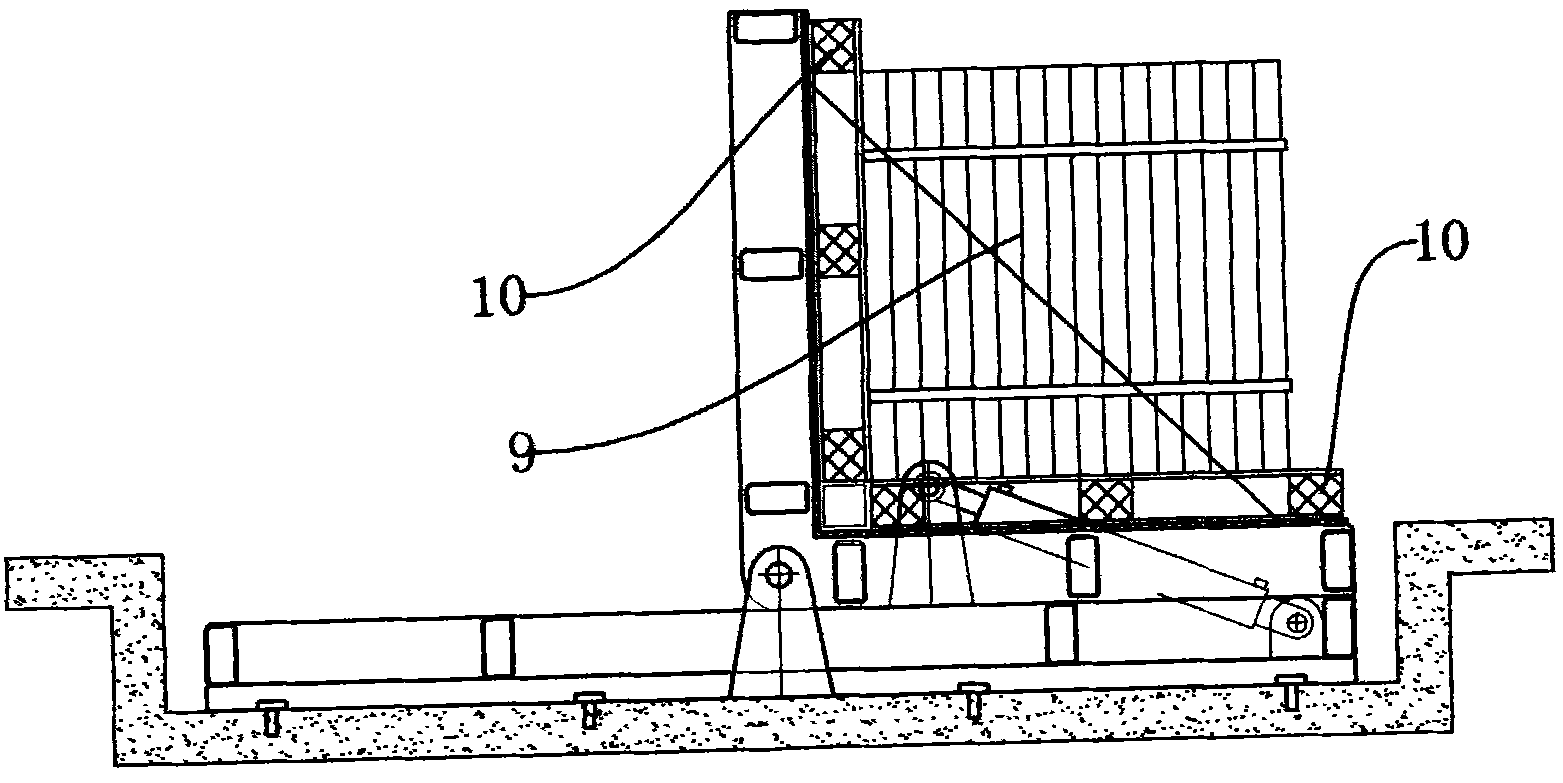

[0019] like Figure 1-2 As shown, the reciprocating turret described in the embodiment of the present invention includes a base 2, a rotary table 4, and a working oil cylinder 5. The base 2 is fixed in the pit 1 by anchor screws 7, and the middle of both sides of the base 2 is provided with Turn the shaft pin assembly 3, the upper side of the base 2 is provided with a rotary table 4, the rotary table 4 is an "L" shaped structure, the bending part of the rotary table 4 is hinged to the rotary shaft pin assembly 3 through a pin shaft Above, the rotary table 4 can rotate the pin shaft assembly 3 to turn over the axis. There is a working oil cylinder 5 between the rotary table 4 and the base 2. The working oil cylinder 5 can push the rotary table 4 to rotate, so that the rotary table 4 Under the action of the working oil cylinder 5, it can rotate 90° back and forth around the rotating pin shaft assembly 3.

[0020] The working oil cylinder 5 is arranged on both sides of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com