Separate-controlled carburetor applicable to intelligent control

A technology of carburetor and oil needle, applied in the direction of machines/engines, etc., can solve the problems of large fluctuations in oil intake, affect control accuracy, impact and friction, etc., achieve low implementation cost, save fuel and discharge, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

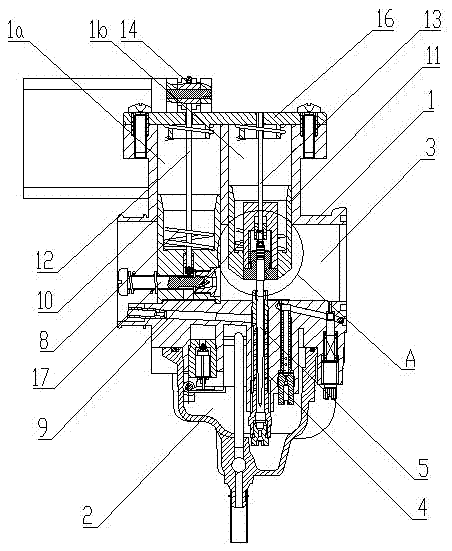

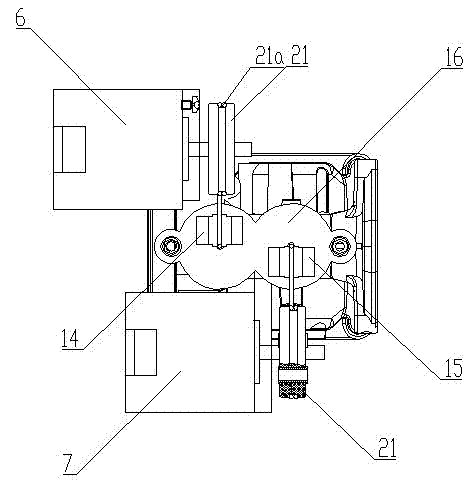

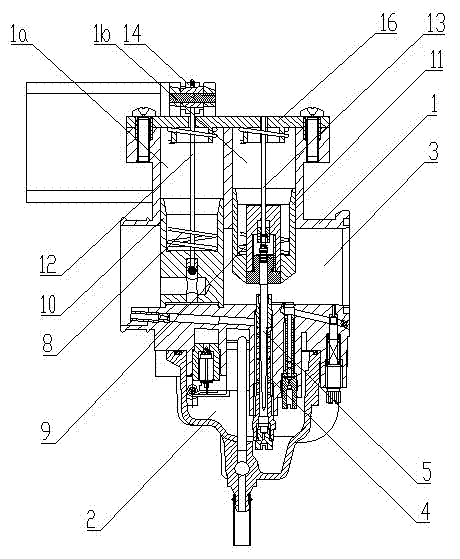

[0028] figure 1 Is a schematic structural diagram of Embodiment 1 of the present invention, figure 2 for figure 1 Top view of Figure 5 for figure 1 A partial enlarged view of A, Image 6 Is a schematic diagram of the structure of the cable roulette, Figure 7 Is the structural diagram of the idle speed adjusting screw part, Picture 8 for Figure 7 AA cross-sectional view, as shown in the figure: the sub-control carburetor suitable for intelligent control of this embodiment includes a main body 1, a float chamber 2, a throat pipe 3 arranged on the main body 1, and a throat pipe 3 The throttle valve, the main nozzle 4 which is arranged on the body 1 and connects the float chamber 2 and the throat 3, and the oil needle 5 whose tip is inserted into the main nozzle 4, and also includes a throttle stepper motor 6, an oil needle stepper motor 7 , Throttle spring 8 and oil needle spring 9, the body 1 is also provided with a valve cylinder tube 1a and a throttle cylinder tube 1b that ...

Embodiment 2

[0035] image 3 Is a schematic structural diagram of Embodiment 2 of the present invention, Figure 4 for image 3 The top view of the carburetor, as shown in the figure: The sub-control carburetor suitable for intelligent control of this embodiment is mainly applied to large-displacement engines. Compared with embodiment 1, the idle speed adjustment screw is removed because of its structure. The large-displacement engine requires a large amount of air intake to adjust during idle speed adjustment, and the change range of the amount of air intake that can be adjusted by the idle speed adjustment screw is relatively small. Therefore, in this embodiment, the throttle stepping motor directly controls the throttle valve rise. To realize the adjustment of the air intake at idling speed, there is no need to set the idling adjustment screw to adjust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com