Keyboard component, preparation method thereof and keyboard

A production method and technology of keyboard components, which are applied in the directions of electrical components, convenient operation, legends, etc., can solve the problems of unstable production, easy linkage, and insufficient rigidity, and achieve high production efficiency, solve linkage, and stabilize mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is used to illustrate the keyboard assembly provided by the present invention and its manufacturing method.

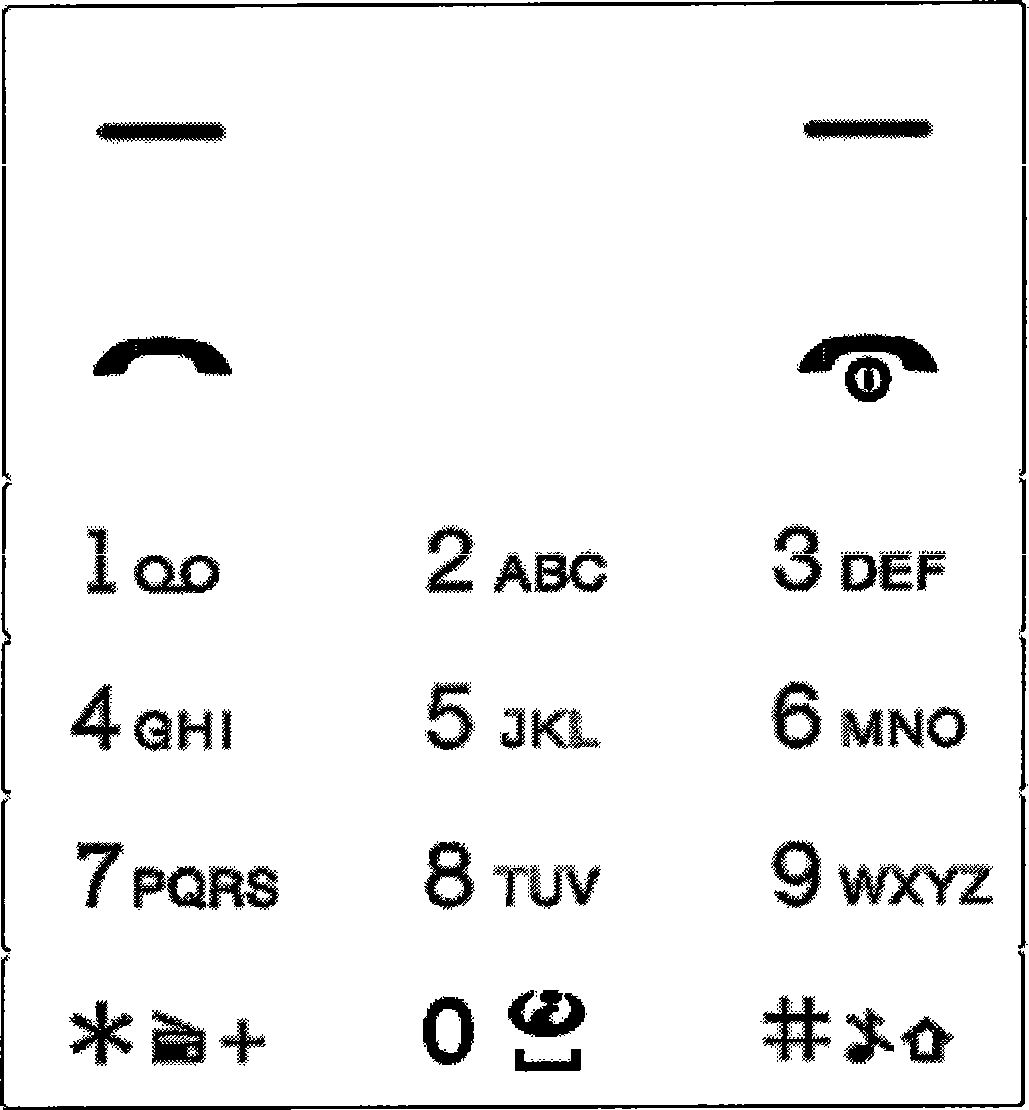

[0047] Print light-guiding ink (Baolai, PF-80923B) on one surface of a PC sheet with a size of 276x175x0.1mm using the method of screen printing to form such as figure 1 As shown in the pattern, then use the method of screen printing to print black ink (Imperial ink of Japan, 1NQ-971) all on the same surface of the PC sheet, and then carry out far-infrared baking to the formed ink layer, The baking temperature is 100° C., and the baking time is 10 minutes.

[0048] Coat the two surfaces of the above-mentioned PC sheet with an activation treatment agent (Shenzhen Cicai Chemical Technology Co., Ltd., 500A and 500B), let it stand and bake at 60°C for 60 minutes, and the activation treatment agent is dried to form a thickness of 0.01 mm bonding layer. Liquid silica gel (Zhongshan Polymeric Electronic Materials Co., Ltd., 9150A and 9150B) is coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com