Variable compression ratio engine

An engine, internal combustion engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as random changes, and achieve the effect of enhancing rigor, improving flexibility, and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

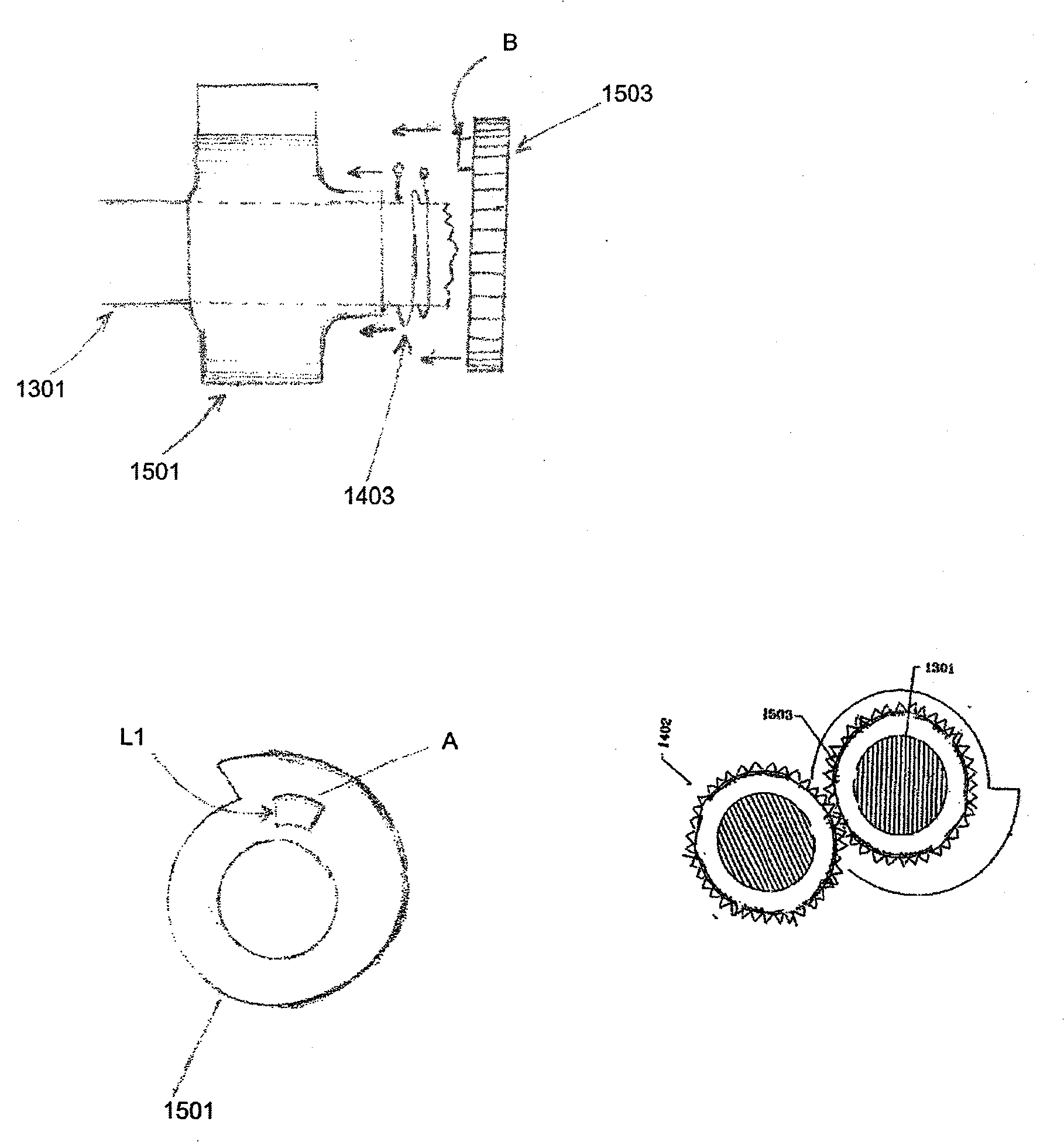

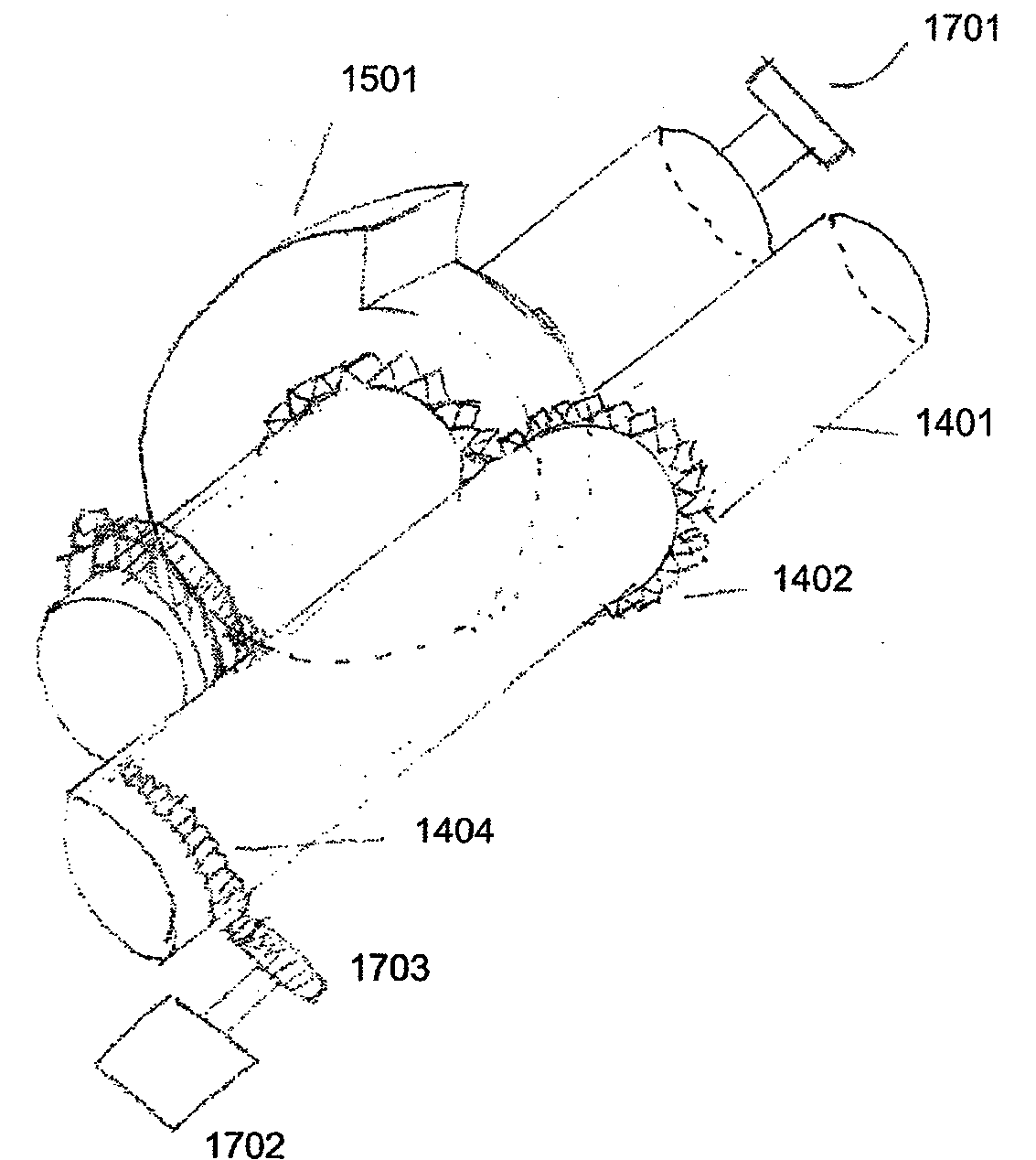

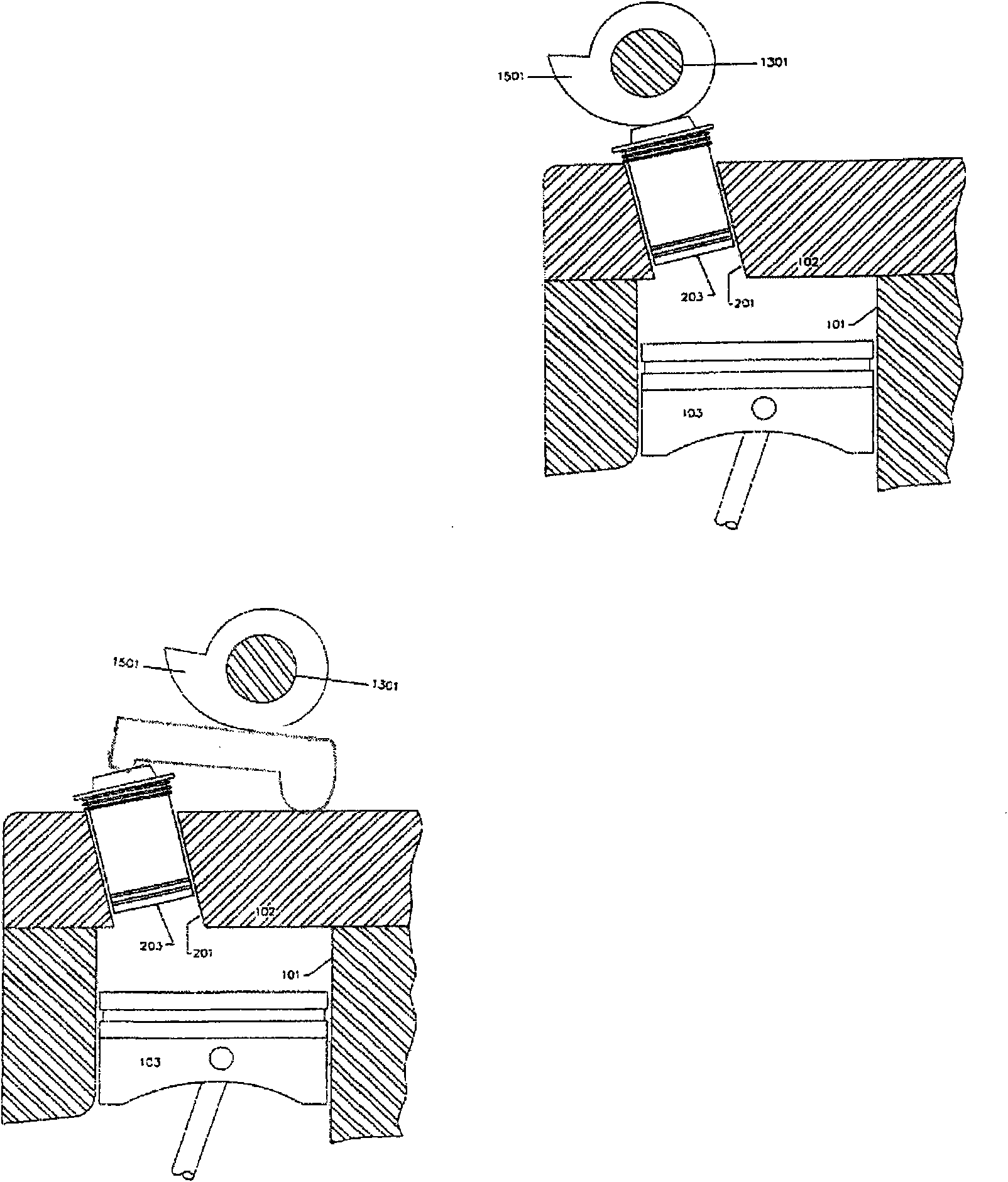

[0027] Referring now to the accompanying drawings, the figure 1 Middle is a cross-sectional view illustrating a cylinder in an internal combustion engine generally indicated at 10 . The engine has a master cylinder 101 , a cylinder head 102 and a master piston 103 . The slave cylinder 201 is formed in the cylinder head 102 and is positioned such that the opening of the slave cylinder 201 communicates with a selected portion of the volume including the interstitial volume at TDC. A sub piston 203 is installed in the sub cylinder 201 . The space below the piston 203 is added to the clearance volume during the calculation of the compression ratio. As the secondary piston descends along the cylinder 201, the clearance volume is reduced and the compression ratio is increased. The opening of the auxiliary cylinder can be made as a narroworifice.

[0028] exist figure 1 In the embodiment shown, the spark plug can be mounted in the secondary piston or elsewhere according to prefe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap