Positioning device for machining multiple coaxial-hole parts

A positioning device and coaxial hole technology, applied in positioning devices, metal processing mechanical parts, metal processing equipment and other directions, can solve the problems of low processing accuracy, difficult processing methods, unable to guarantee the coaxiality requirements, etc., and achieve high positioning accuracy. , to ensure the effect of coaxiality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

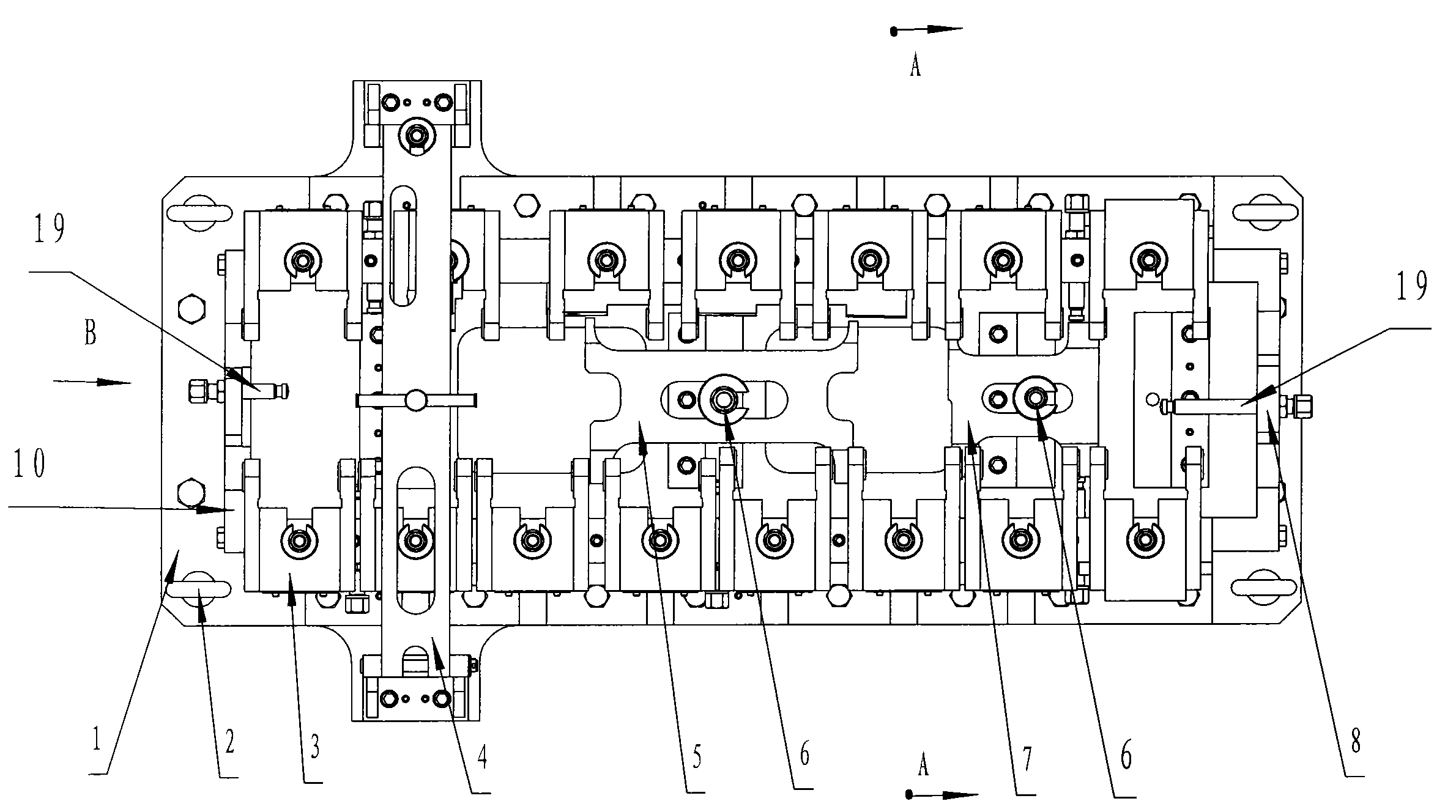

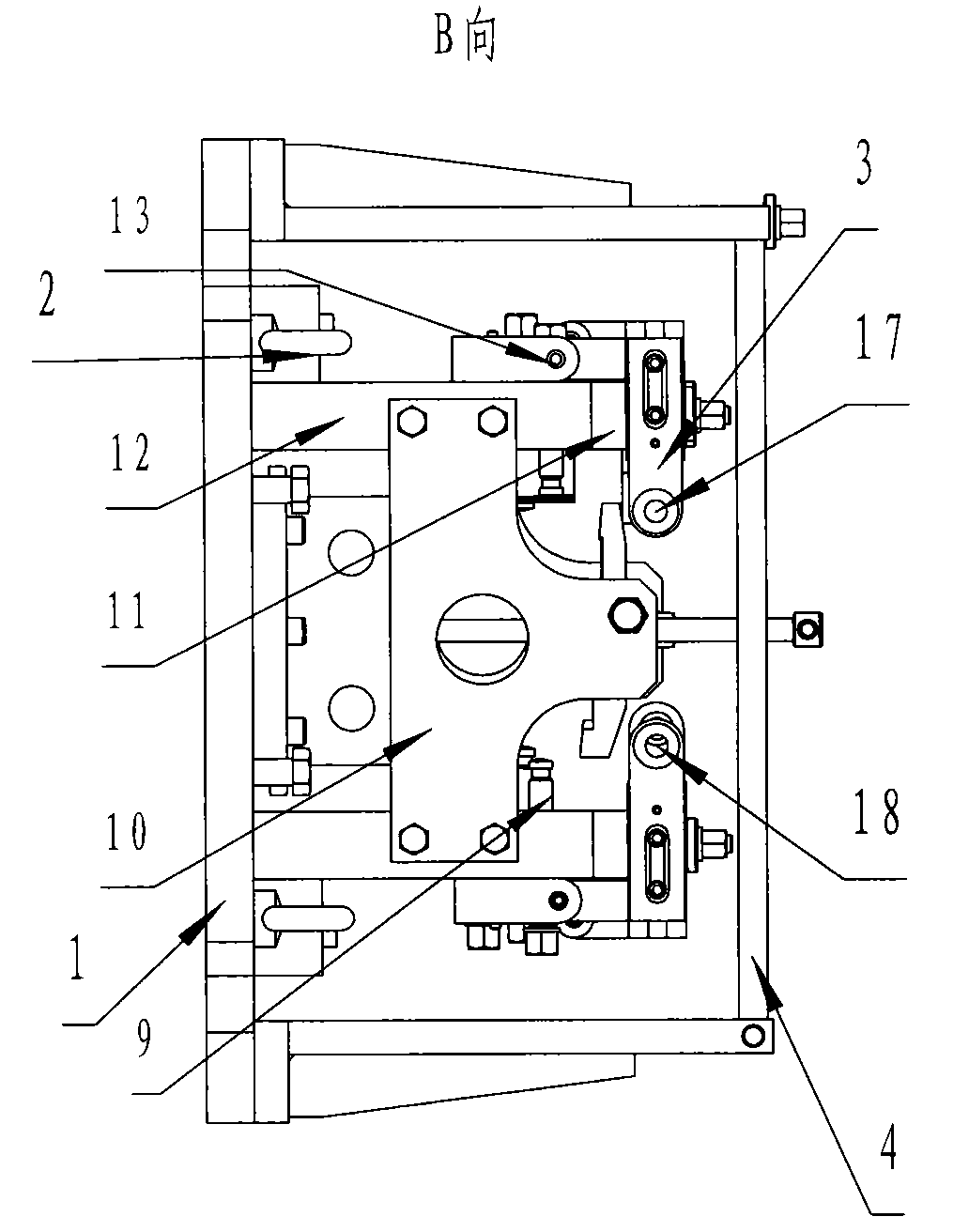

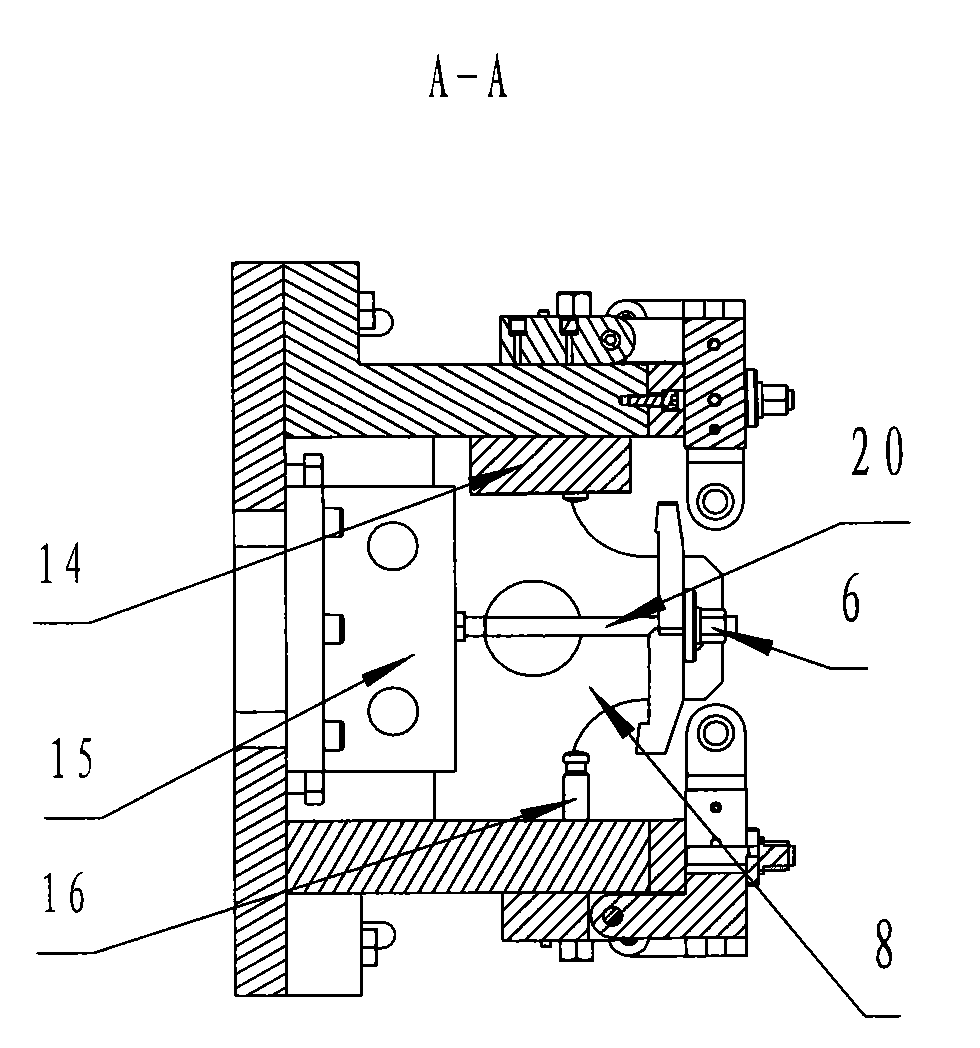

[0009] The positioning device for processing multiple coaxial hole parts is characterized in that it consists of a base, a lifting lug, a drilling guide template, a reversible pressing device, a clamping part pressing plate I, a pressing nut, a clamping part pressing plate II, an end Head baffle, horizontal clamping bolt I, end limit plate, drilling guide formwork support guide rail, guide rail support, drilling guide formwork turning shaft, transverse positioning block, support seat, transverse clamping bolt II, drilling guide Template guide sleeve I, drilling guide template guide sleeve II, positioning bolts and bolts are composed. Four lifting lugs are screwed at the four corners of the base to lift the whole device to the processing machine tool. One guide rail support is installed on each side, and the drilling guide template is installed on the guide rail support to support the guide rail. The support seat is installed on the base between the two guide rail supports to lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com