Sensor for detecting high-precision corner and torque of precision mechanism

A precision mechanism and high-precision technology, applied in the direction of torque measurement, instruments, measuring devices, etc., can solve the problems of inconvenient use and difficulty, and achieve the effect of convenient installation, fewer components and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

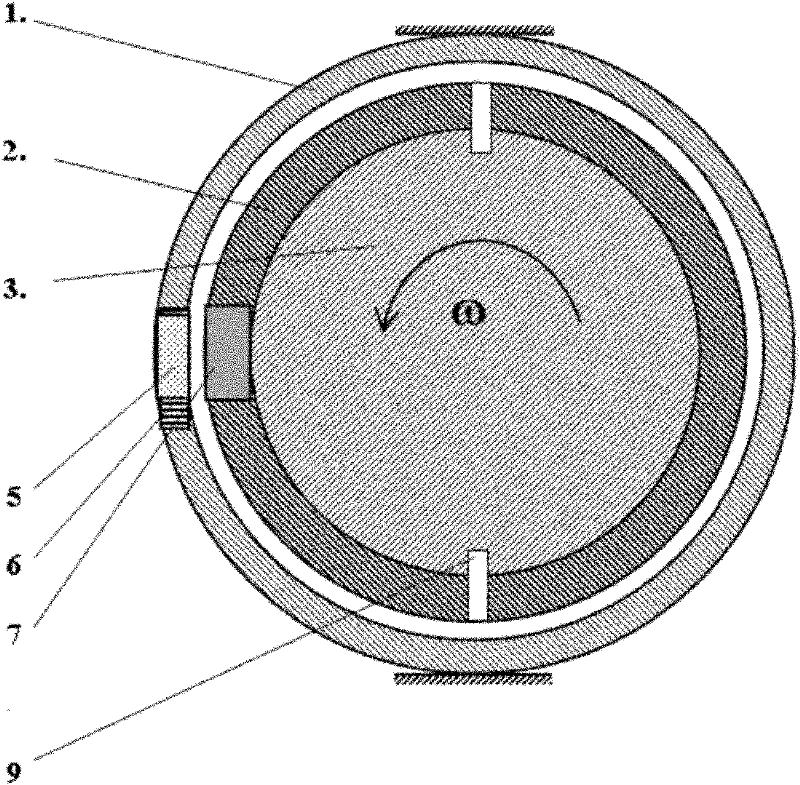

Examples

Embodiment 2

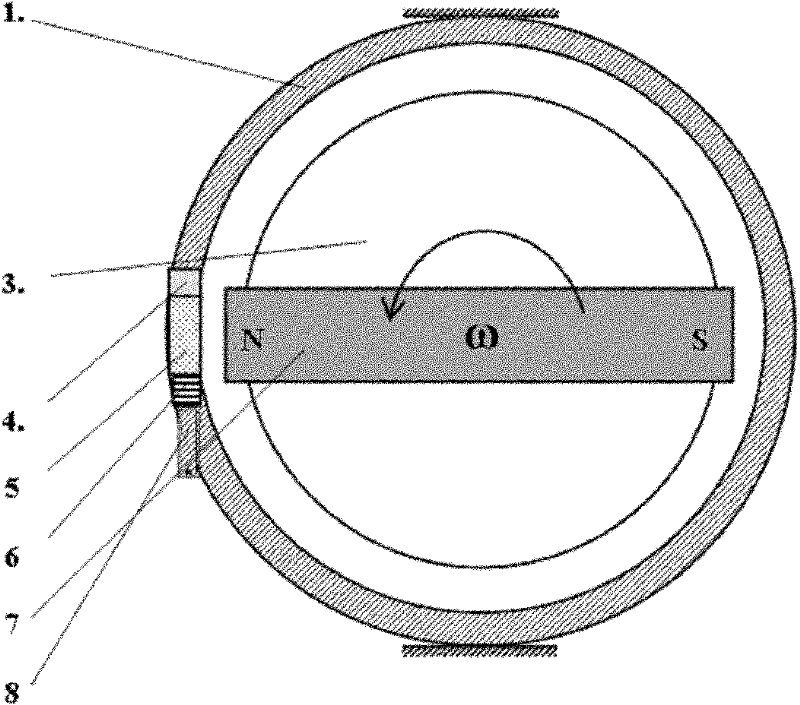

[0030] like figure 2As shown, this embodiment includes: a fixed sleeve 1, a rotating shaft 3, a magnetic bias permanent magnet 4, a magneto-deformable body 5, a force conversion body 6, an excitation permanent magnet 7 and a sensor body fastener 8, wherein: the fixed The sleeve 1 and the rotating shaft 3 are sequentially socketed from the outside to the inside, the excitation permanent magnet 7 is arranged on the rotating shaft 3, the magnetic bias permanent magnet 4, the magnetic deformation body 5, the force conversion body 6 and the sensor body fastener 8 are sequentially arranged They are fixedly connected in series and arranged on the fixed sleeve 1.

[0031] The excitation permanent magnet 7 is arranged on the outer end surface of the rotating shaft 3. In this case, rotating the rotating shaft 3 or directly rotating the permanent magnet 7 (such as rotating by hand) can also realize the corresponding function that can be detected in embodiment 1.

Embodiment 3

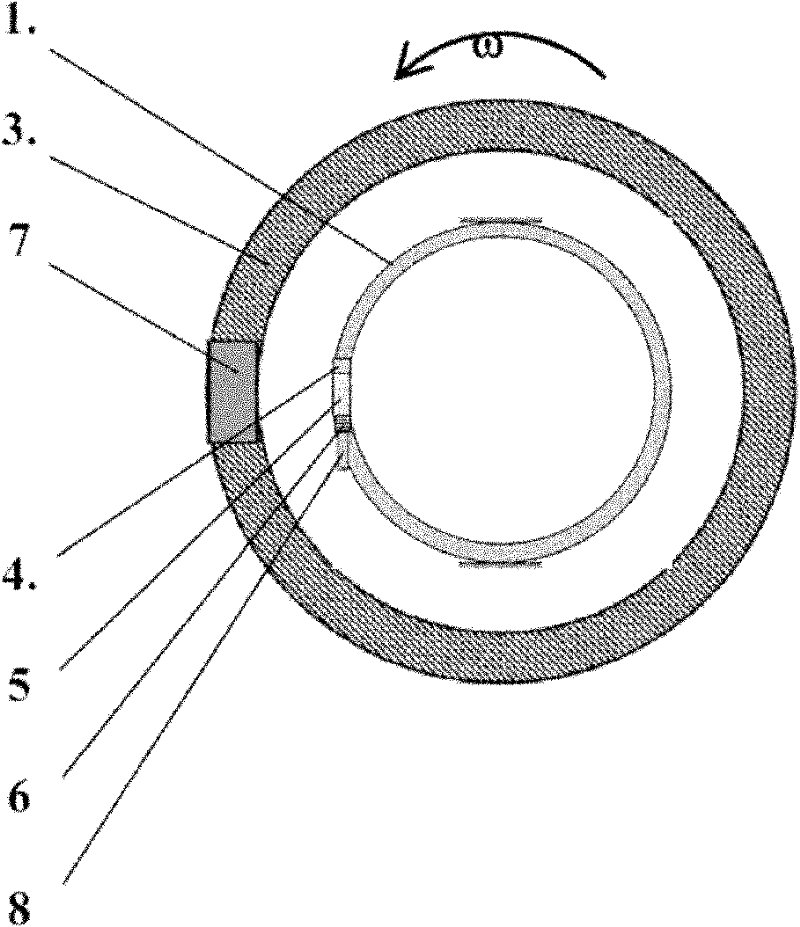

[0033] like image 3 As shown, the rotating shaft 3 described in this embodiment has a tubular structure, and the outer casing 1 and its sensing body are placed inside the rotating shaft 3 to realize various sensing functions described in the above embodiments.

[0034] Through the above-mentioned device and implementation technical link, this device generates the change of the corresponding electric / magnetic signal by detecting the force conversion body 6 on the sensing body excited by the excitation permanent magnet 7 during the rotation process. The sensor of the proposed device for the rotation of the rotating shaft can be used as a torque sensor for the rotating shaft under the rotation angle or quasi-static torque. Secondly, by calibrating the corresponding relationship between the generated electric / magnetic signal and the excitation permanent magnet 7, that is, the rotation angle or the phase change of the rotation cycle of the rotation shaft 3 before and after the est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com