Method for measuring surface flatness of light wave array surface or optical reflective surface

A technology of optical reflection and flatness, applied in the field of optical detection, can solve the problems that the parameters of each unit cannot be completely consistent, the light wave array surface is not practical, and the processing is not easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention is described in detail below in conjunction with accompanying drawing:

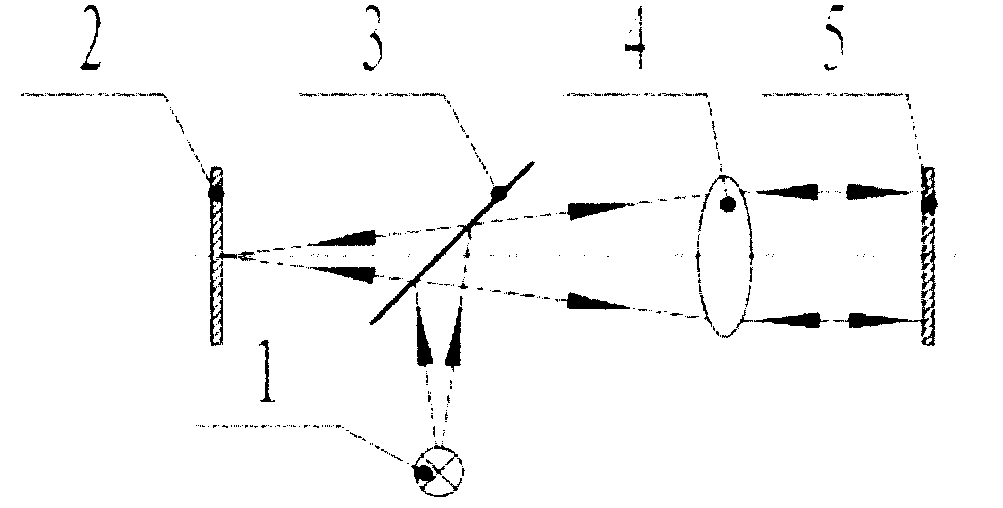

[0024] figure 1 is the structure diagram of the light pipe. The optical target beam is generated by the target generator 1 , and the beam is emitted out of the light pipe through the beam splitter 3 and the lens group 4 , and the beam is reflected by the reflector 5 and then received by the detector 2 . If the mirror deflects, the beam angle will also deflect, and the position of the beam projected on the detector will change and be received and recorded, so as to calculate the deflection angle of the mirror.

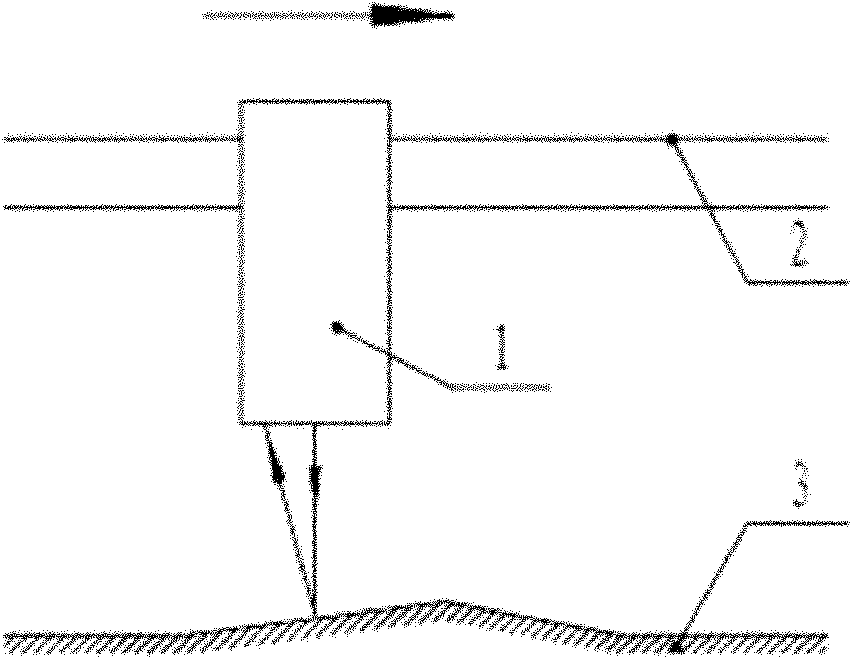

[0025] Use the light pipe directly to scan, then if figure 2 shown. If the area to be measured is an optical reflective surface, the inclination of the reflective surface in the area is calculated by receiving the reflected beam of the light beam emitted by the light pipe detector, and the surface flatness of the entire optical reflective surface is m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap