Flue gas sampling equipment

A technology of flue gas sampling and equipment, applied in the direction of sampling devices, etc., can solve the problems of no purging effect, unresolved filter element clogging, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

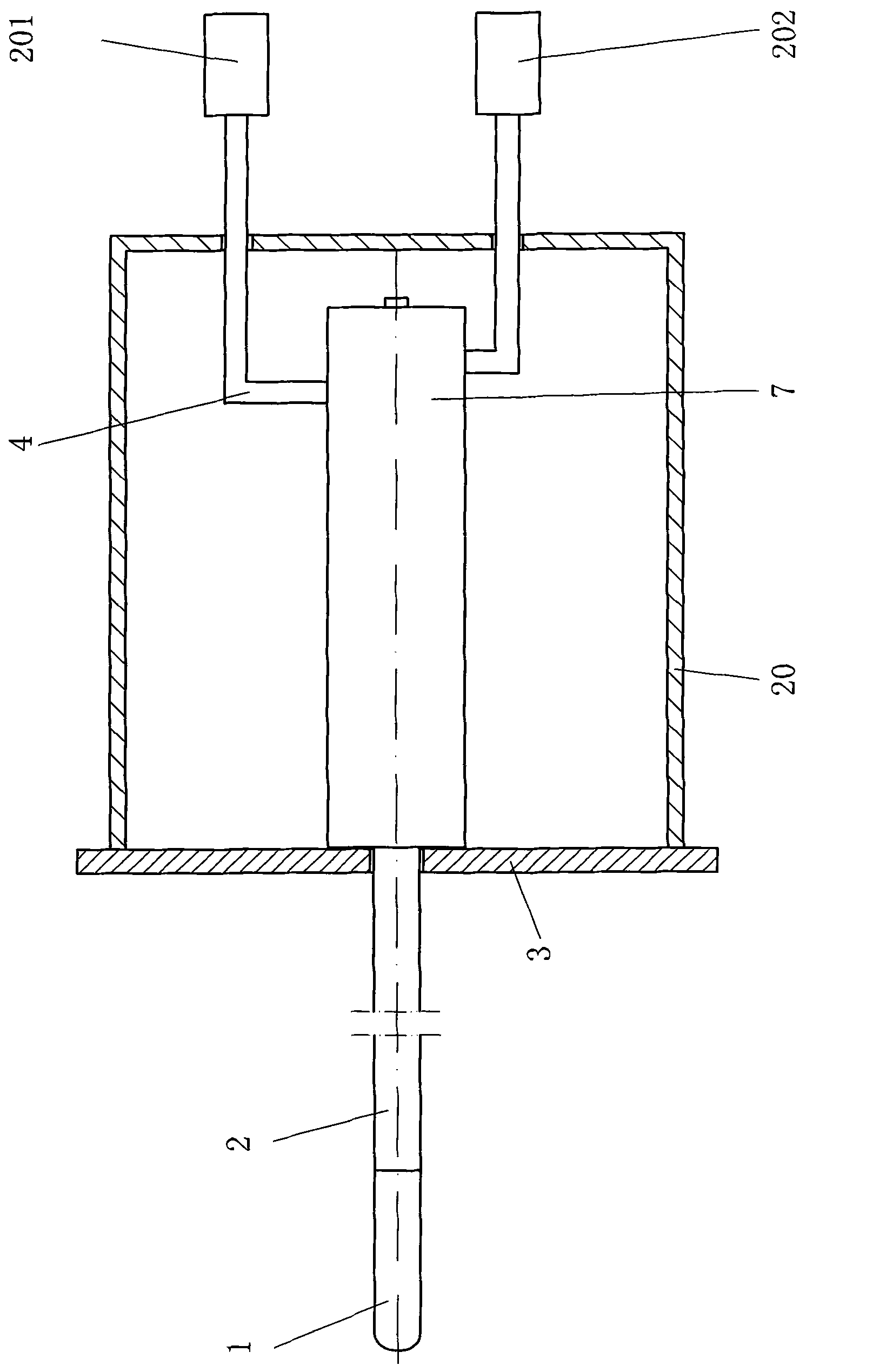

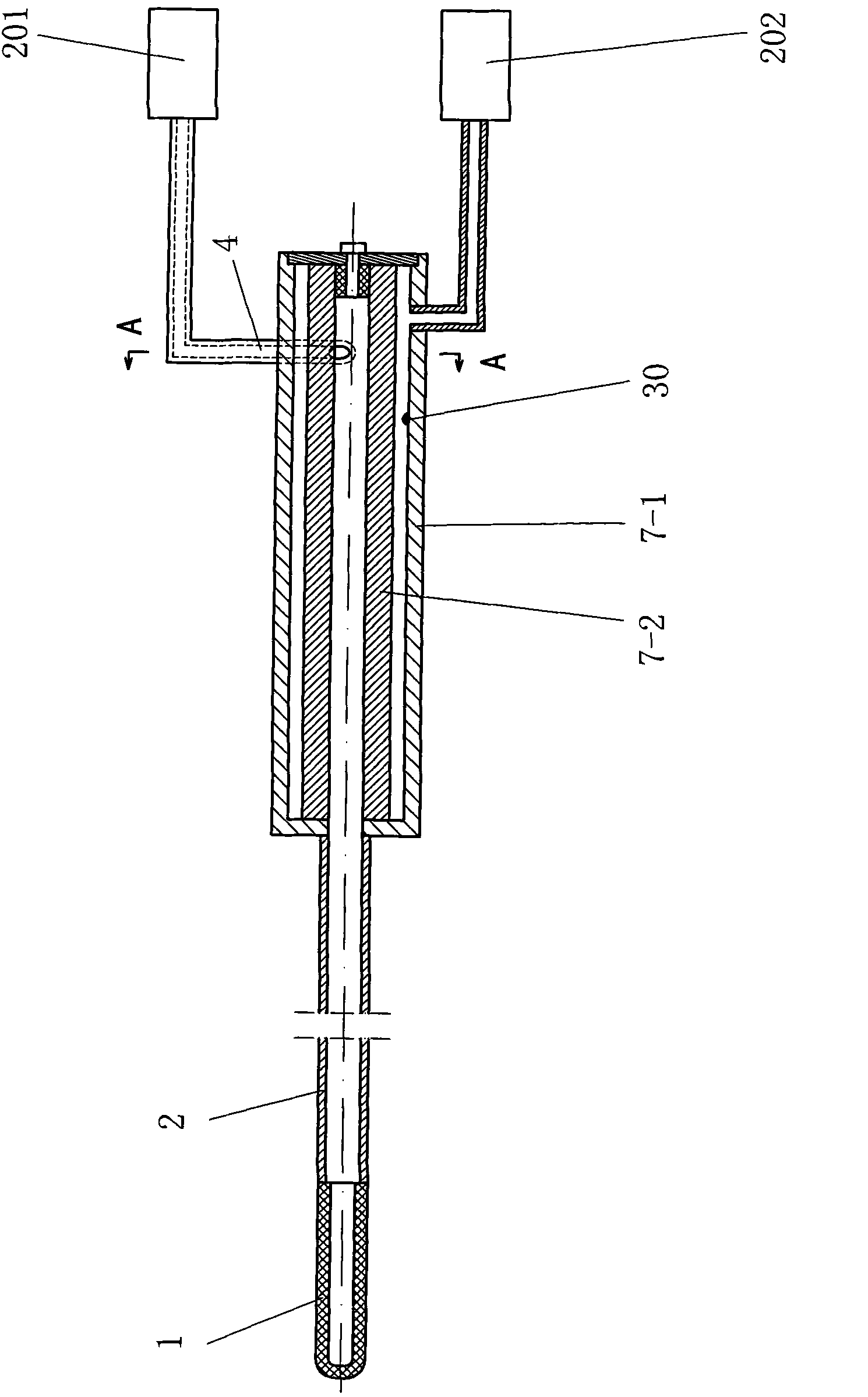

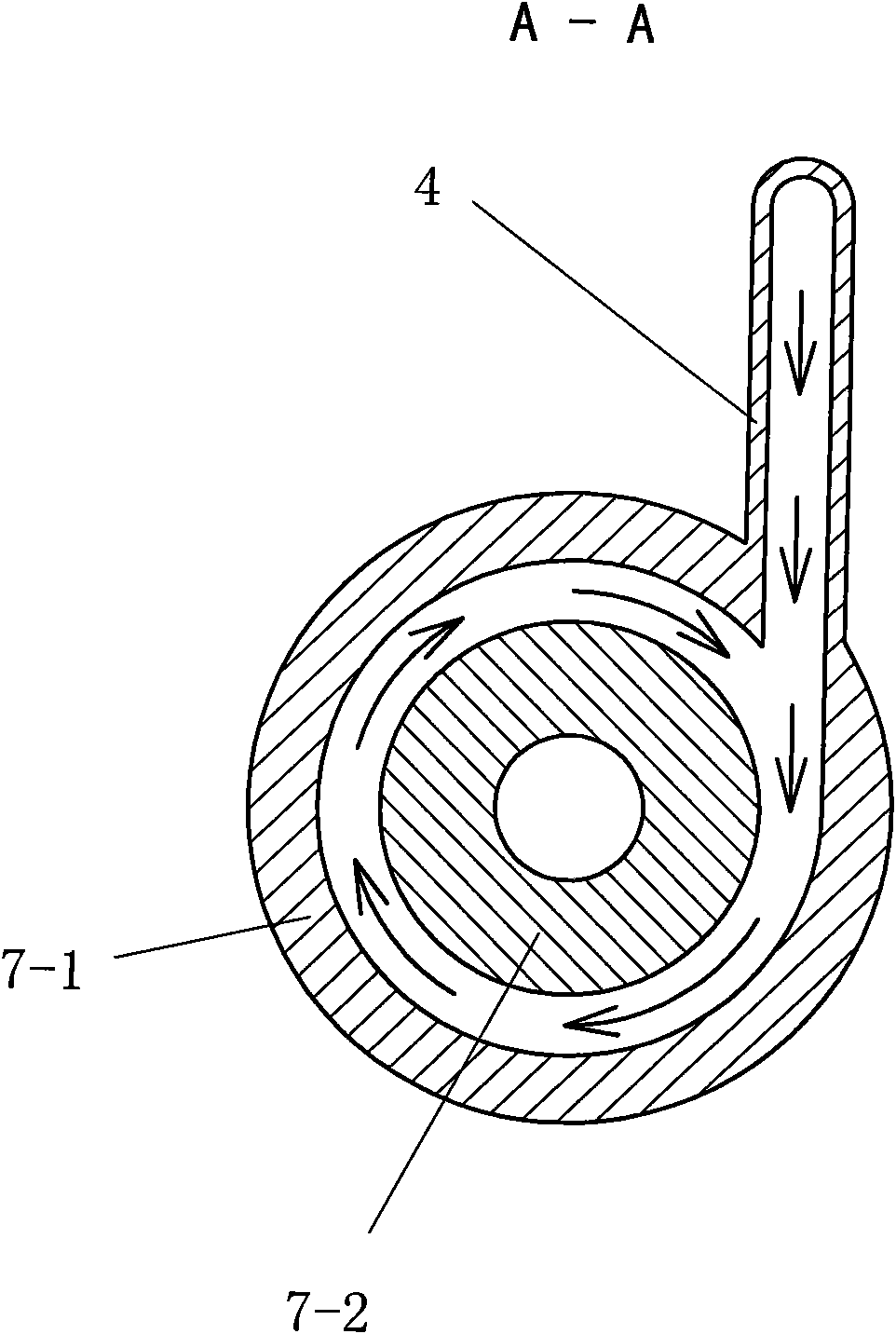

[0067] according to Figure 1 to Figure 11 Expressed content, making flue gas sampling equipment.

[0068] Drawing description: figure 1 is one of the schematic diagrams of the device of the present invention; figure 2 is the second schematic diagram of the device of the present invention; image 3 yes figure 2 A-A sectional view in , and enlarged, the magnification ratio is 3:1; Figure 4 It is a schematic diagram of the filter element in the built-in filter; Figure 5 yes Figure 4 left view of Image 6 It is a schematic diagram of the connection between the built-in filter housing and the blowback air pipe; Figure 7 yes Image 6 left view of Figure 8 yes Image 6 top view of Figure 9 yes Image 6 right view of Figure 10 yes Figure 8 C-C sectional view of ; Figure 11 yes Image 6 B-B direction sectional view. 1. Pre-filter; 2. Probing rod; 3. Mounting plate; 4. Blowback air pipe; 7. Built-in filter; 7-1. Outer cover; 7-2. Shell; 30. Probe; 201. Air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com