Rotary piston internal combustion engine power unit

A power unit, rotary technology, applied in the field of rotary piston internal combustion engine power units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

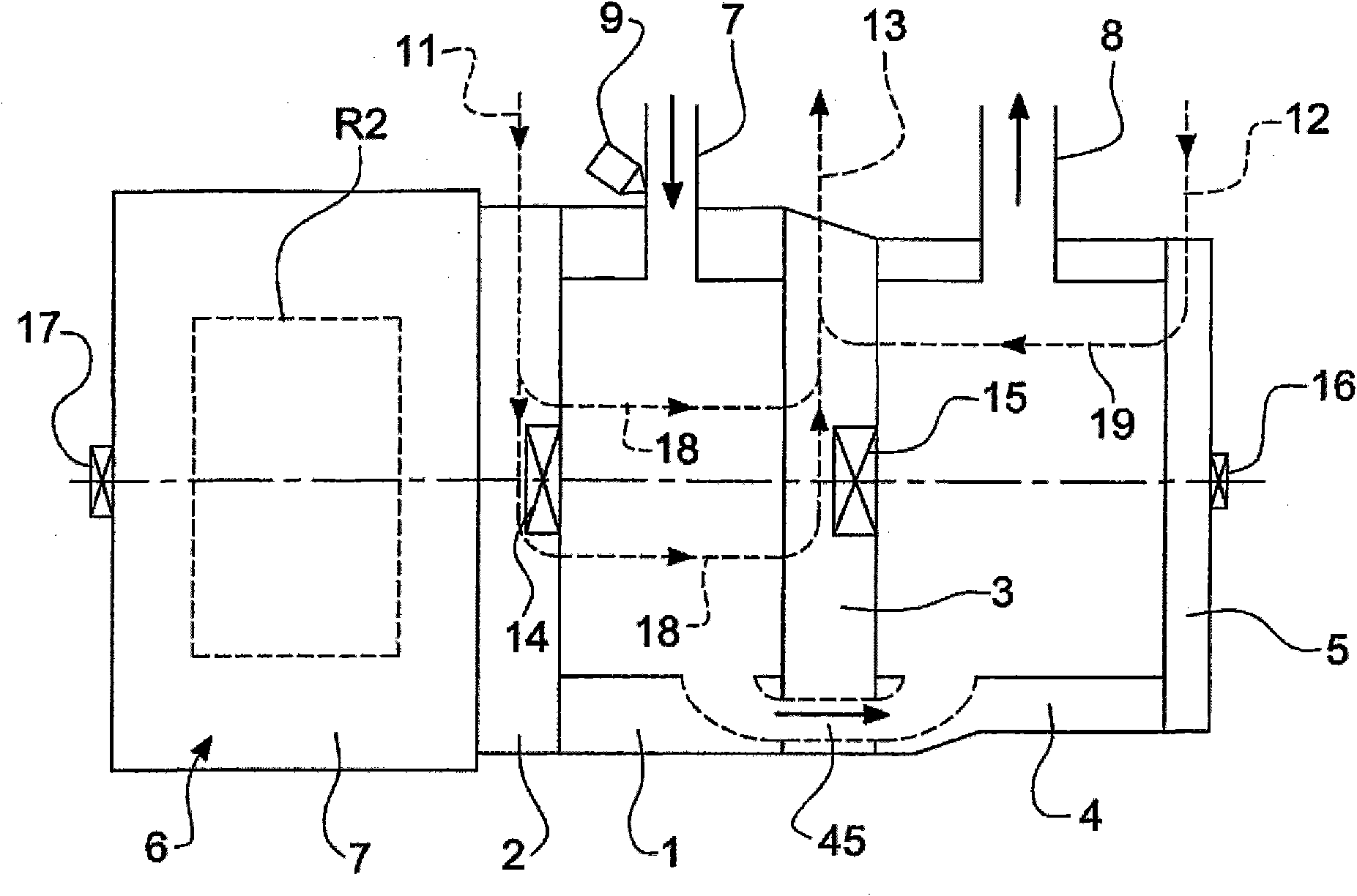

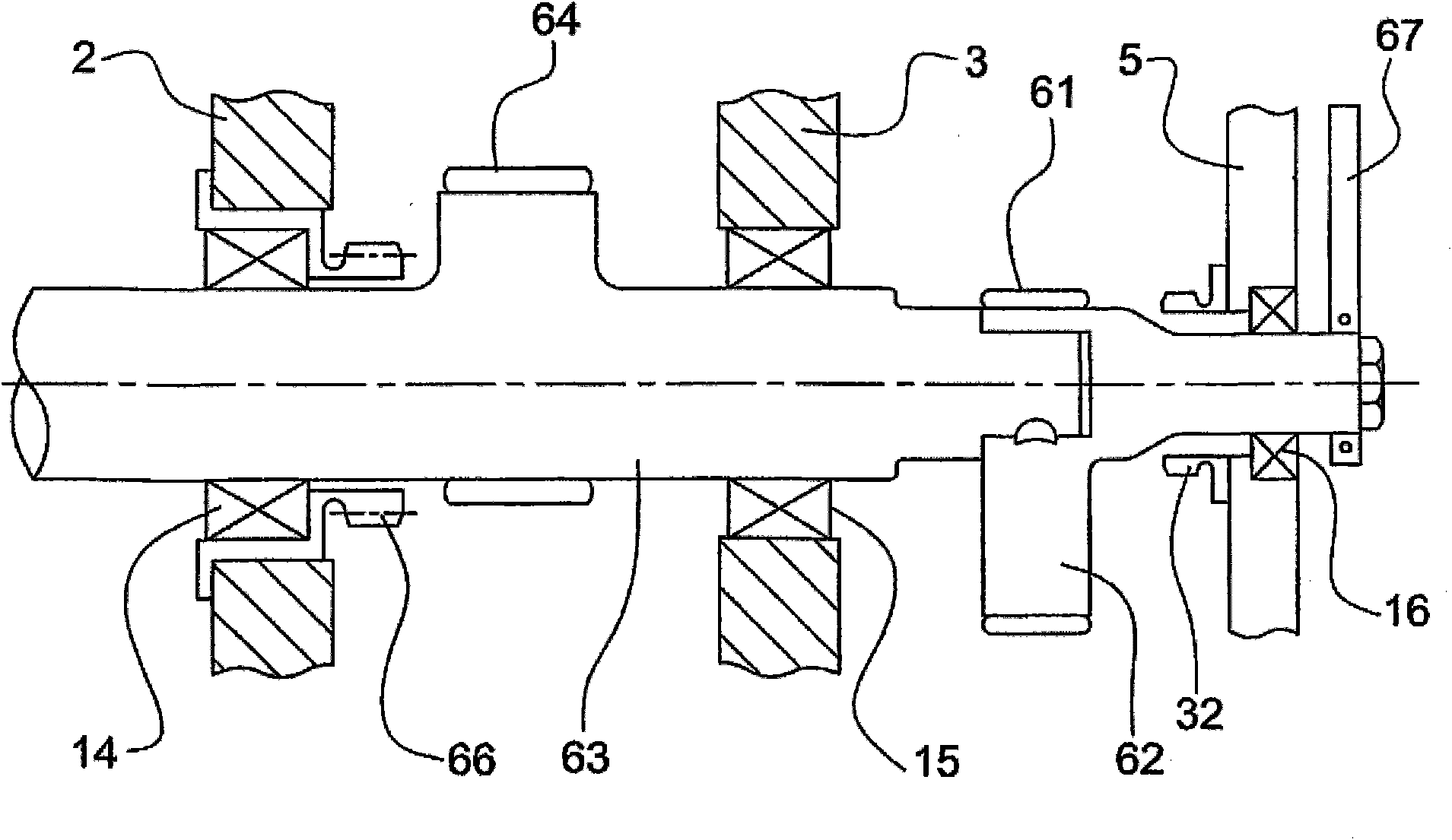

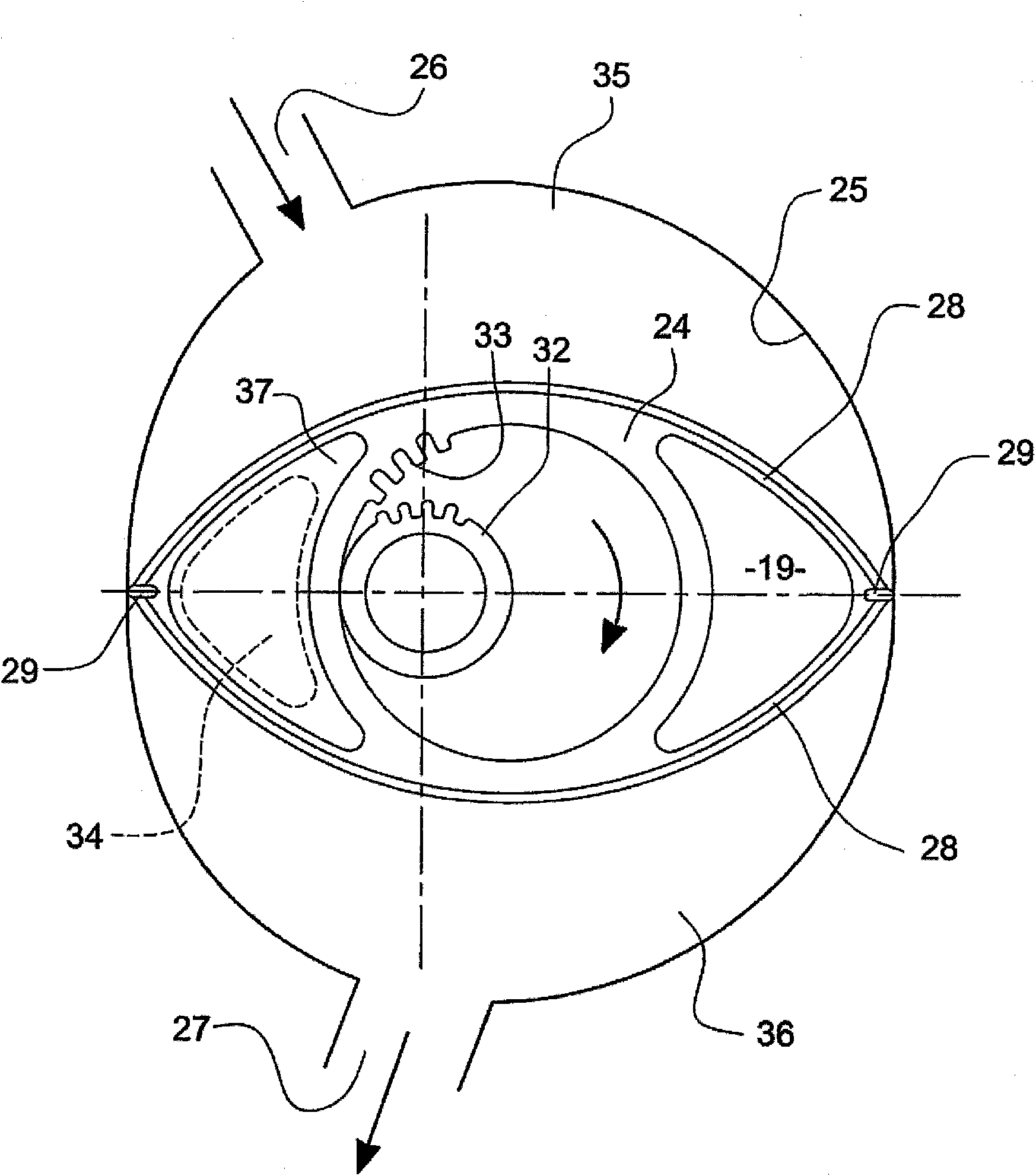

[0035] refer to figure 1 with 2 , the engine unit includes a rotor housing 1, end sleeves 2 and 3, and an introduction pipe 7. The expander unit is mounted coaxially with the engine unit and projects outwardly from the engine unit through a shared composite end sleeve 3 . The expander unit includes a rotor housing 4 , an outer end sleeve 5 and a discharge pipe 8 . The rotor 24 of the expander unit (see image 3 ) meshes with the stationary gear 32 and is mounted on an extension 62 of the motor eccentric shaft 63 which is journalled in two main bearings 14, 15 mounted in the end sleeves 2, 3 respectively. The small tail bearing 16 of the expander unit is depicted adjacent to the external counterweight 67 . The shafts 63, 62 of the engine unit and expander unit are thus connected for common rotation.

[0036] The expander unit rotor 24 rotates at half the speed of the shaft 62 on which the expander unit rotor 24 is mounted.

[0037] For engine unit rotor R (see Figure 8)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com