Long round pipe inner surface processing equipment and process thereof

A technology for processing equipment and inner surfaces, applied in metal processing equipment, manufacturing tools, honing machine tools, etc., can solve problems such as difficult processing of the inner surface of long round tube parts, achieve good processing effects, improve performance, and solve the effect of finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] I. Clamping of the workpiece

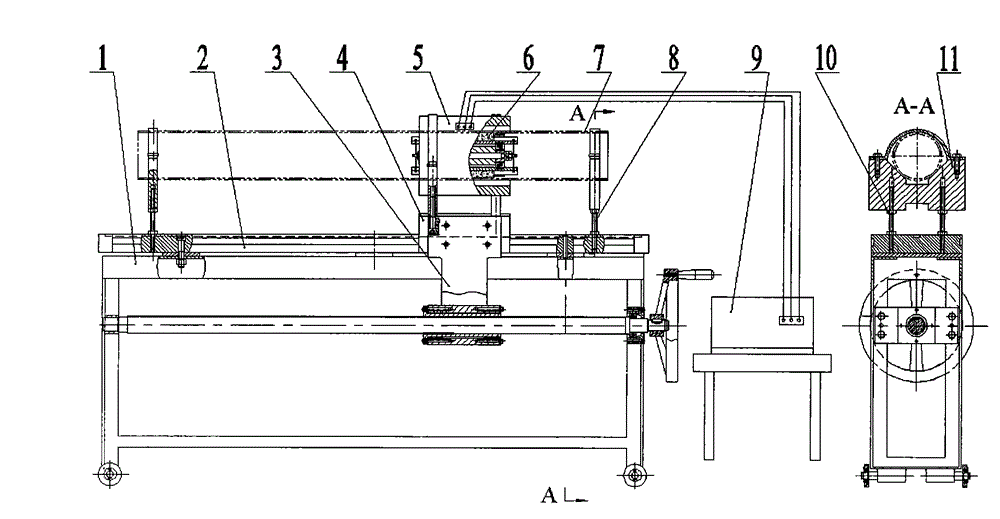

[0021] combined with figure 1 , specifically to further elaborate how the round tube part 7 is clamped. Firstly, the φ108×4 3m long stainless steel round tube part 7 with an inner cavity of oxide skin passes through the stator type magnetic field generator 5 and is positioned and clamped on the V-shaped positioning block 11, and the center height of the round tube part 7 is adjusted by the adjusting nut 10 Make it coaxial with the magnetic field generator 5 to complete the clamping of the workpiece;

[0022] II. Magnetic rough honing

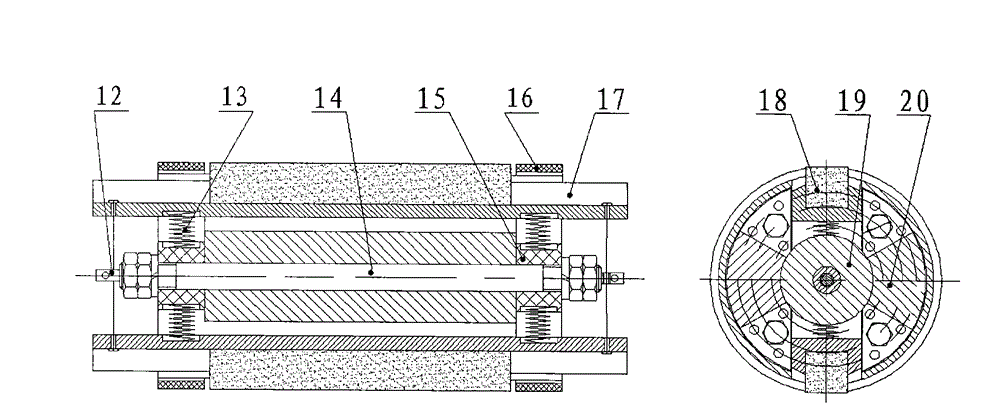

[0023] combined with figure 1 , attached figure 2 , specifically to further elaborate how the inner surface of the round tube part 7 realizes the magnetic rough honing. Put the rotor honing head 6 equipped with 80# brown corundum grinding block into the inner cavity of the round tube part 7, the specific operation is as follows: turn the elastic rod 12, the top spring 13 is pressed, the grinding block ...

Embodiment approach 2

[0027] I. Clamping of the workpiece

[0028] Same as Embodiment 1;

[0029] II. Magnetic rough honing

[0030] The grinding block on the rotor honing head 6 is selected from 100 # The brown corundum grinding block, the three-phase symmetrical winding of the stator magnetic field generator 5 is connected to the three-phase symmetrical AC current, the frequency is adjusted to 40HZ, the rotor honing head 6 will rotate at a speed of 1200r / min with the rotating magnetic field, and the screw nut is fed The mechanism 3 moves the stator type magnetic field generator 5 along the axial direction at a speed of 4m / min to realize the longitudinal feed of the rotor honing head 6; after the double-stroke processing, the blank defects and scales on the inner surface of the round tube part 7 can be removed, and other same Embodiment 1;

[0031] III. Magnetic fine honing

[0032] The grinding block on the rotor honing head 6 is selected from 160 #The brown corundum grinding block, the thre...

Embodiment approach 3

[0034] I. Clamping of the workpiece

[0035] Same as Embodiment 1;

[0036] II. Magnetic rough honing

[0037] The grinding block on the rotor honing head 6 is selected from 120 # The brown corundum grinding block, the three-phase symmetrical winding of the stator magnetic field generator 5 is connected to the three-phase symmetrical alternating current, the frequency is adjusted to 45HZ, the rotor honing head 6 will rotate at a speed of 1350r / min with the rotating magnetic field, and the screw nut is fed The mechanism 3 moves the stator type magnetic field generator 5 along the axial direction at a speed of 3m / min to realize the longitudinal feed of the rotor honing head 6; after the double-stroke processing, the blank defects and oxide scales on the inner surface of the round tube part 7 can be removed, and other same Embodiment 1;

[0038] III. Magnetic fine honing

[0039] The grinding block on the rotor honing head 6 is selected from 200 # The brown corundum grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com