Bar chamfering machine and control method thereof

A control method and chamfering machine technology, applied in the direction of automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of poor chamfering quality, high labor intensity, and low processing efficiency, and achieve the goal of finishing difficult problems, improve processing quality, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

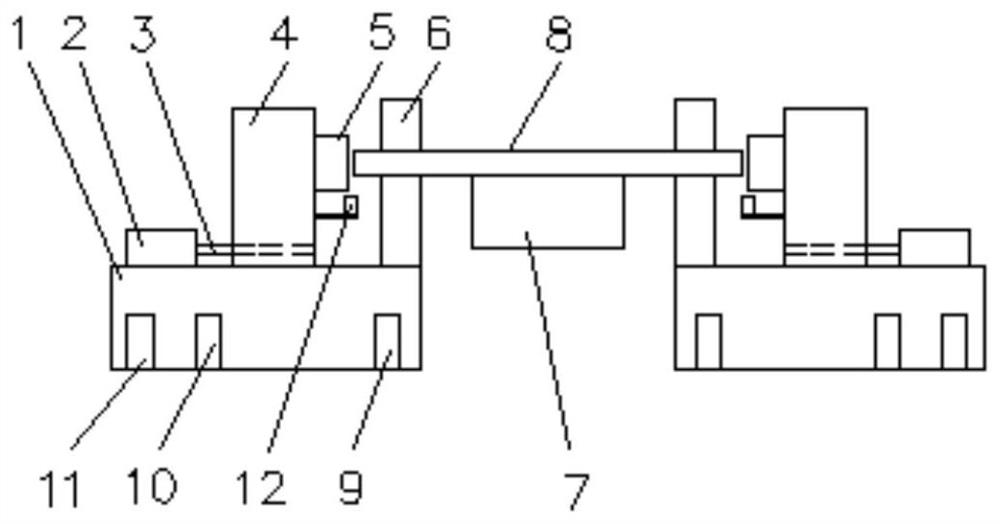

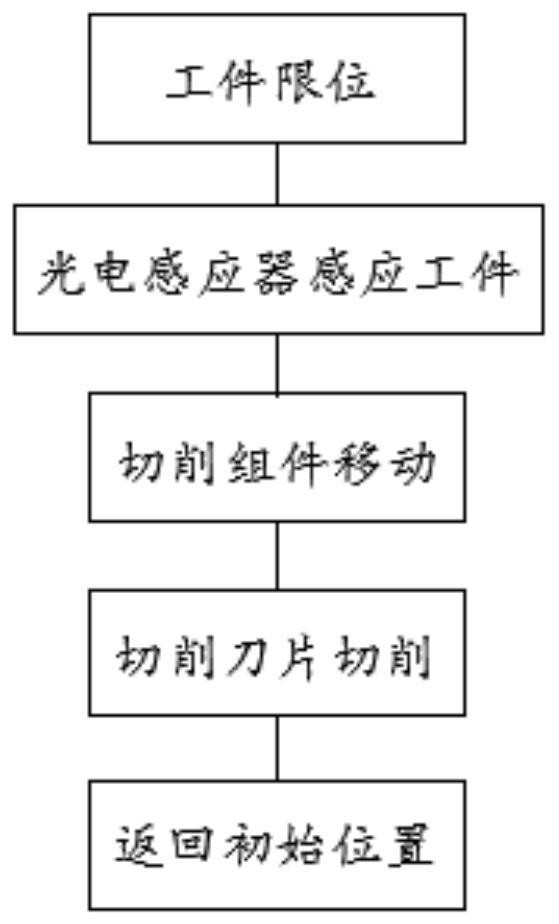

[0030] see figure 1 , a bar chamfering machine, including:

[0031] The body 1, the body 1 includes the left and right bodies 1 and is respectively arranged on the left and right sides of the feeding mechanism 7, the body 1 is provided with guide rails, and the cutting assembly 5 is slidably connected to the guide rails; the sensor limit control assembly is fixedly connected;

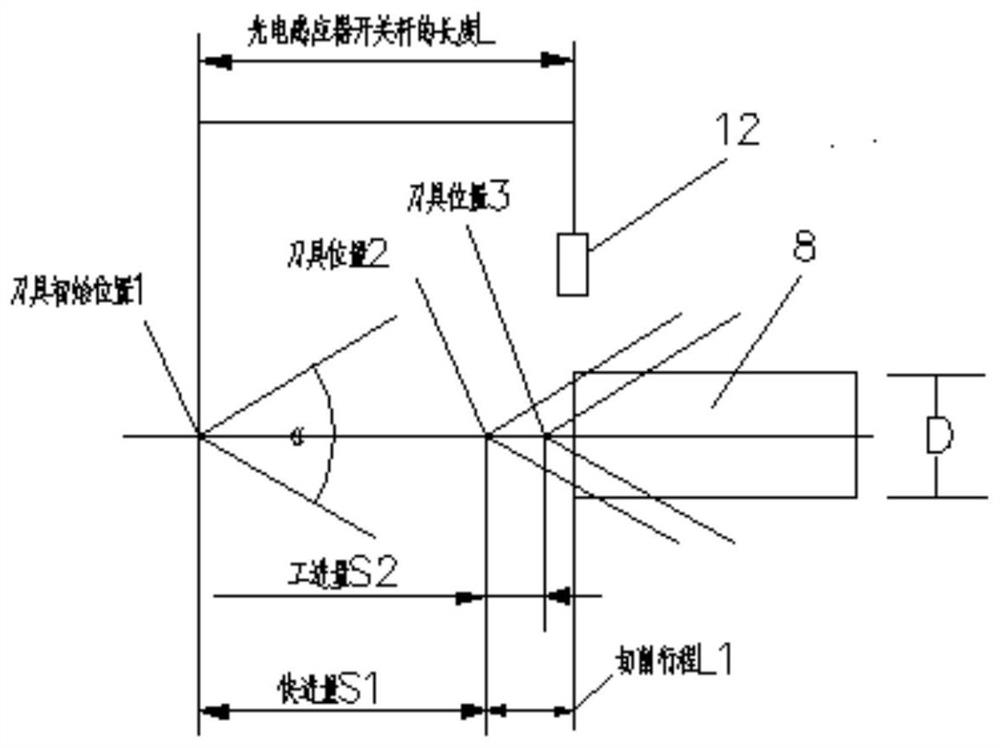

[0032] The cutting assembly 5 includes a rotary cutter cylinder, which is fixedly connected to a rotary drive member, and the rotary drive member is dynamically connected to the sliding drive membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com