Machining equipment for high-grade steel pipe end surfaces with large apertures and wall thicknesses

A processing equipment and large-diameter technology, which is applied to the processing equipment for the end face of high-grade steel pipes, large wall thickness, and large-diameter fields. It can solve the problems of poor equipment stability, poor processing quality, and difficult processing, and achieve high processing capacity and quality Good, range-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

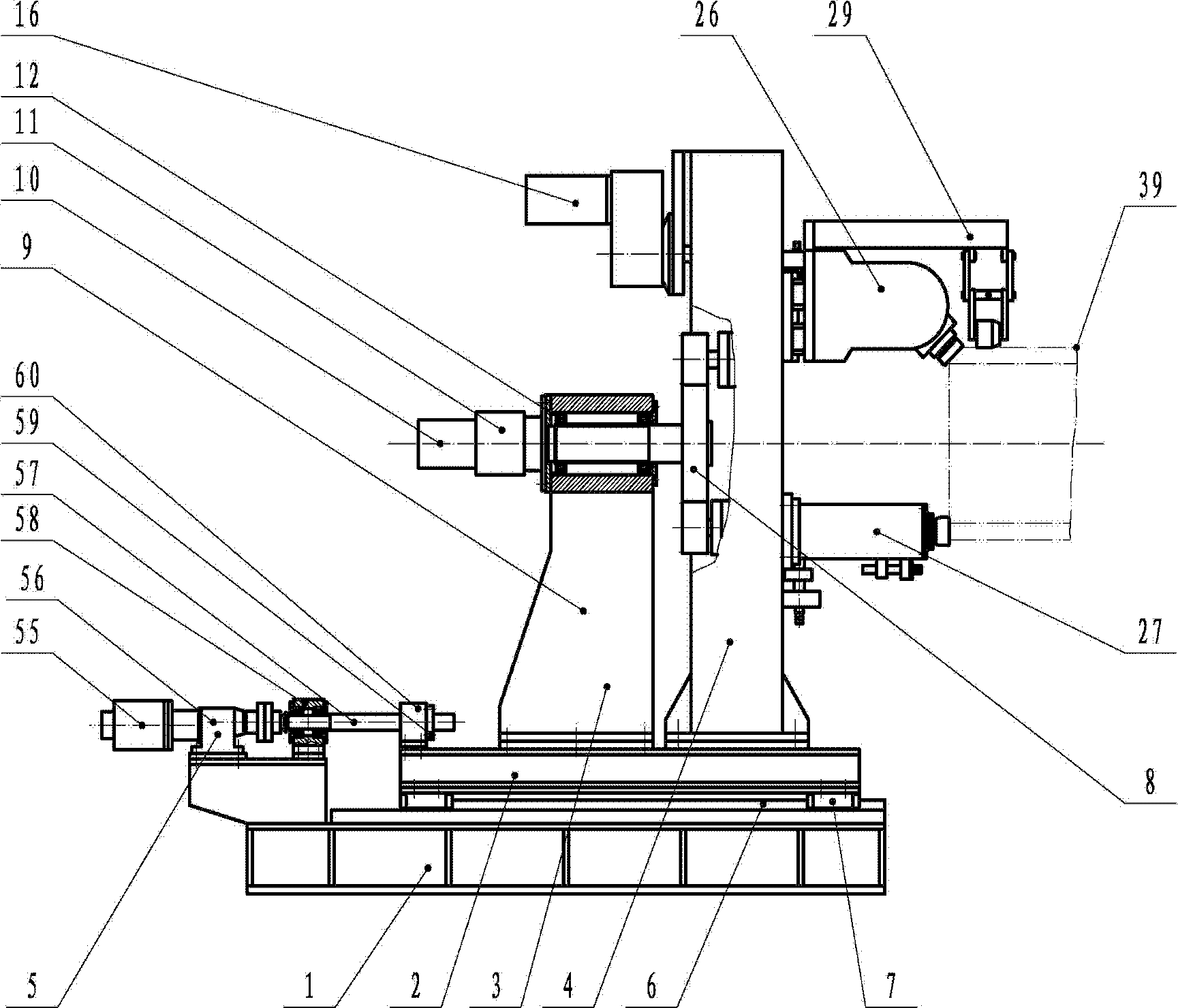

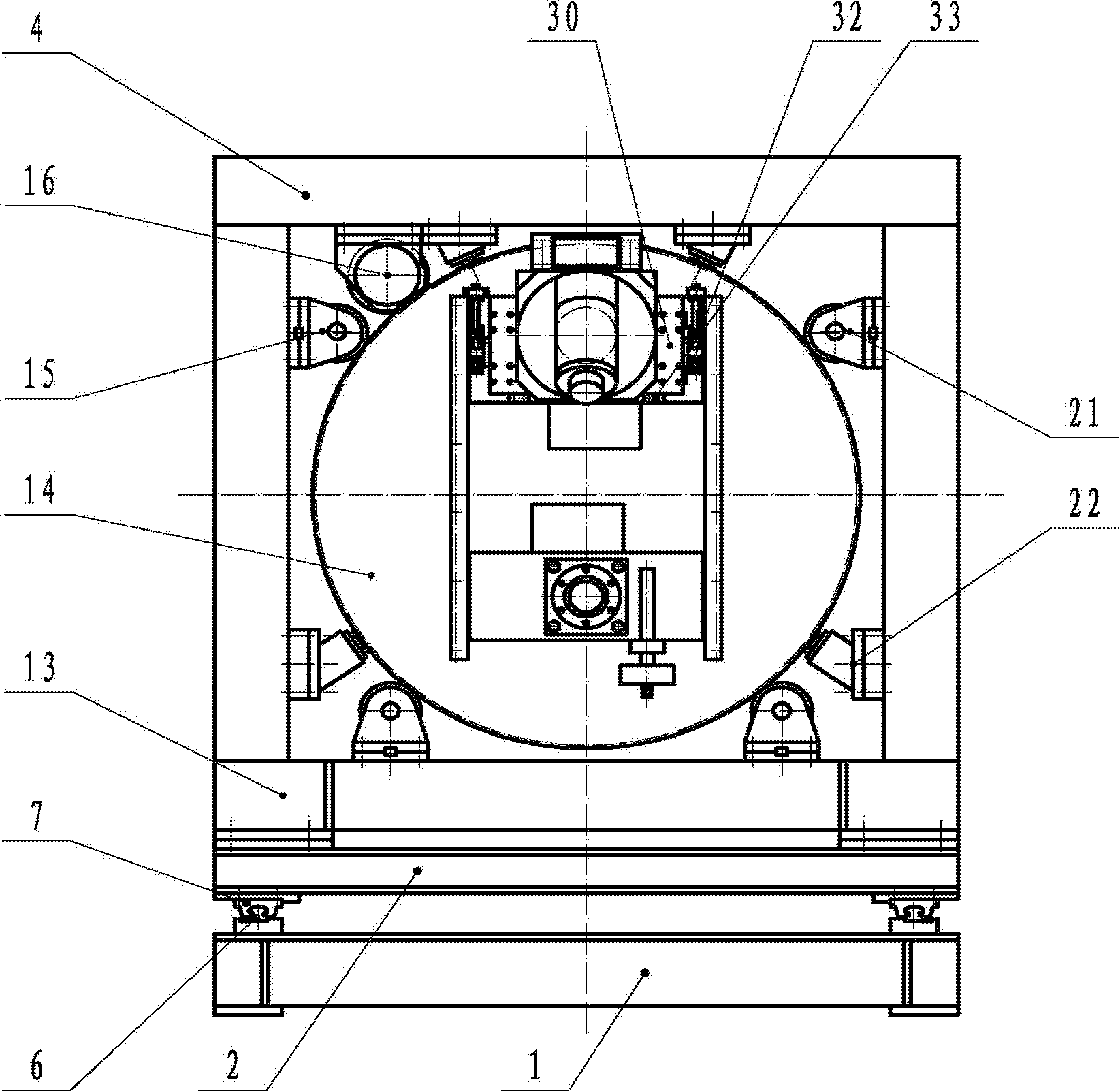

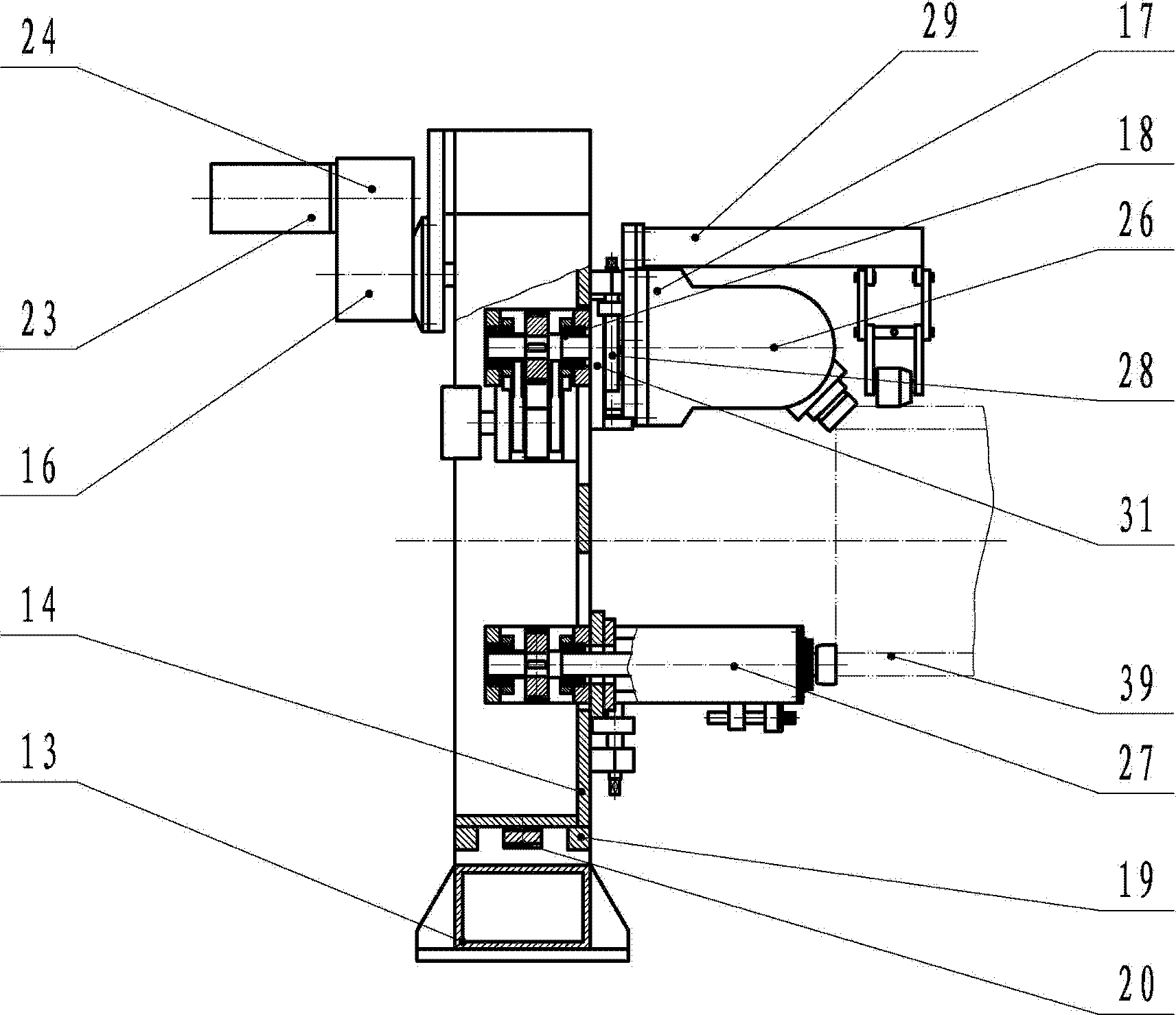

[0024] A processing equipment for the end face of large-diameter, large-wall-thick, high-grade steel pipes, such as figure 1 , figure 2 As shown, it includes a fixed base 1, a mobile base 2, a central gear transmission support device 3, a special power head 4 and a feed mechanism 5,

[0025]The fixed base 1 is a steel plate welded plate structure, the lower surface is installed on the foundation, and two linear guide rails 6 are installed on the upper surface;

[0026] The mobile base 2 is a steel plate welded plate structure, the lower surface is equipped with a slider 7 and forms a sliding fit with the linear guide rail 6 of the fixed base;

[0027] The central gear transmission supporting device 3 includes a transmission mechanism, a central gear 8 and a support seat 9, and the transmission mechanism and the central gear 8 are respectively cantilever-mounted on both ends of the support seat 9. The transmission mechanism is composed of a motor 10 and a reducer 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com