Machining equipment for high-grade steel pipe end surfaces with large apertures and wall thicknesses

A kind of processing equipment and large-diameter technology, which is applied in the field of large-diameter, high-grade steel pipe end face processing equipment and large wall thickness, can solve the problems of poor equipment stability, poor processing quality, difficult processing, etc., and achieve large processing capacity and high quality. Good, the effect of range improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

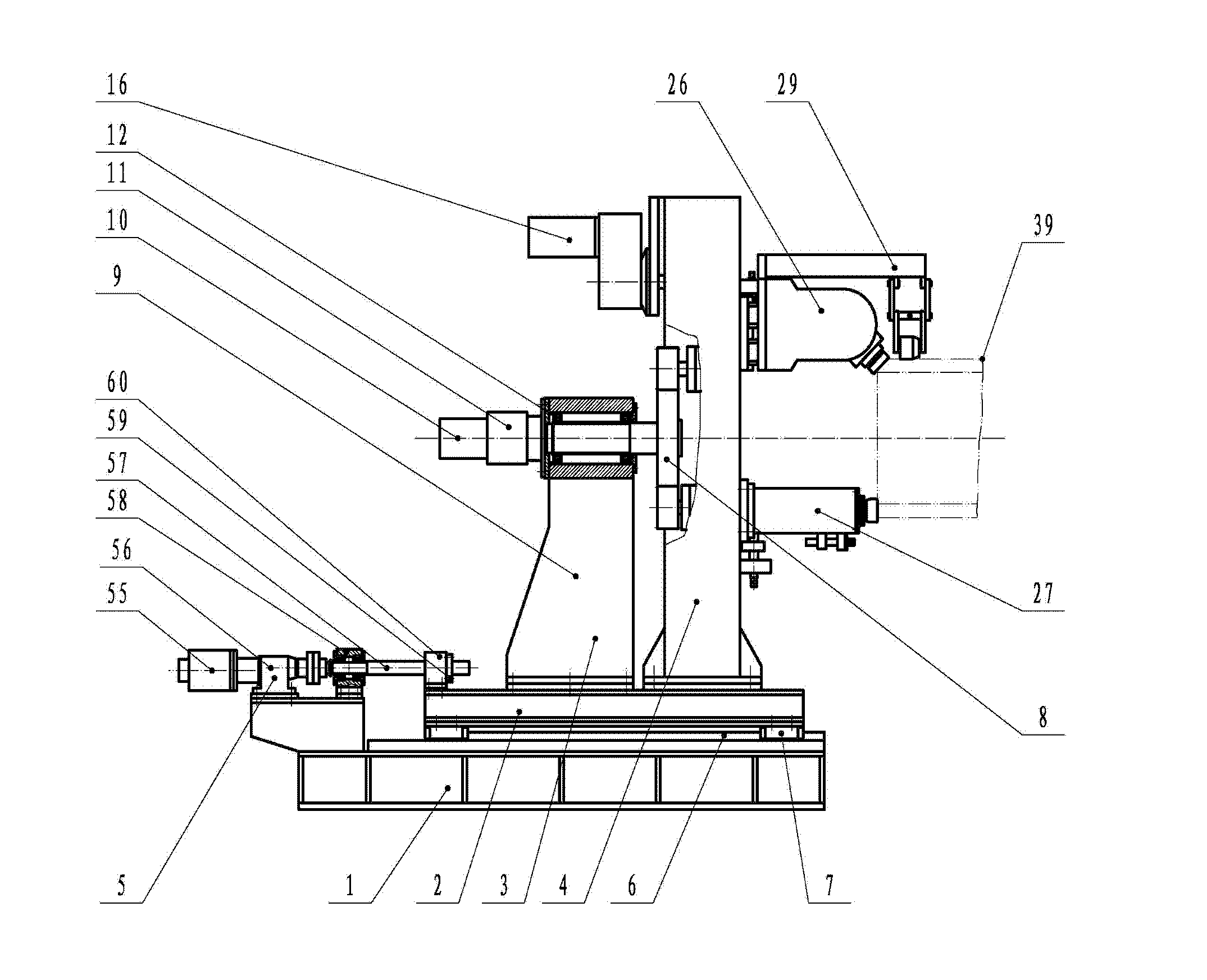

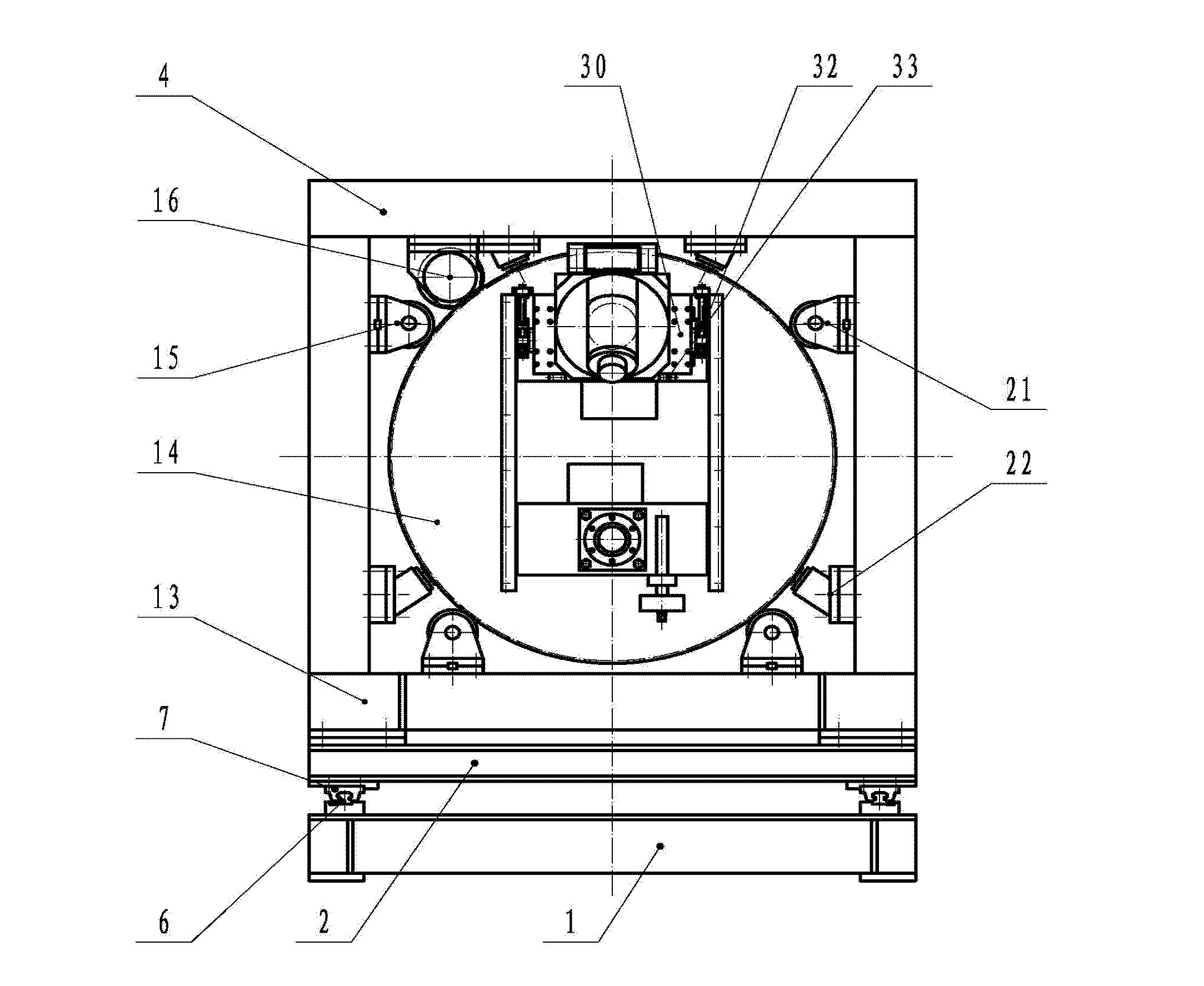

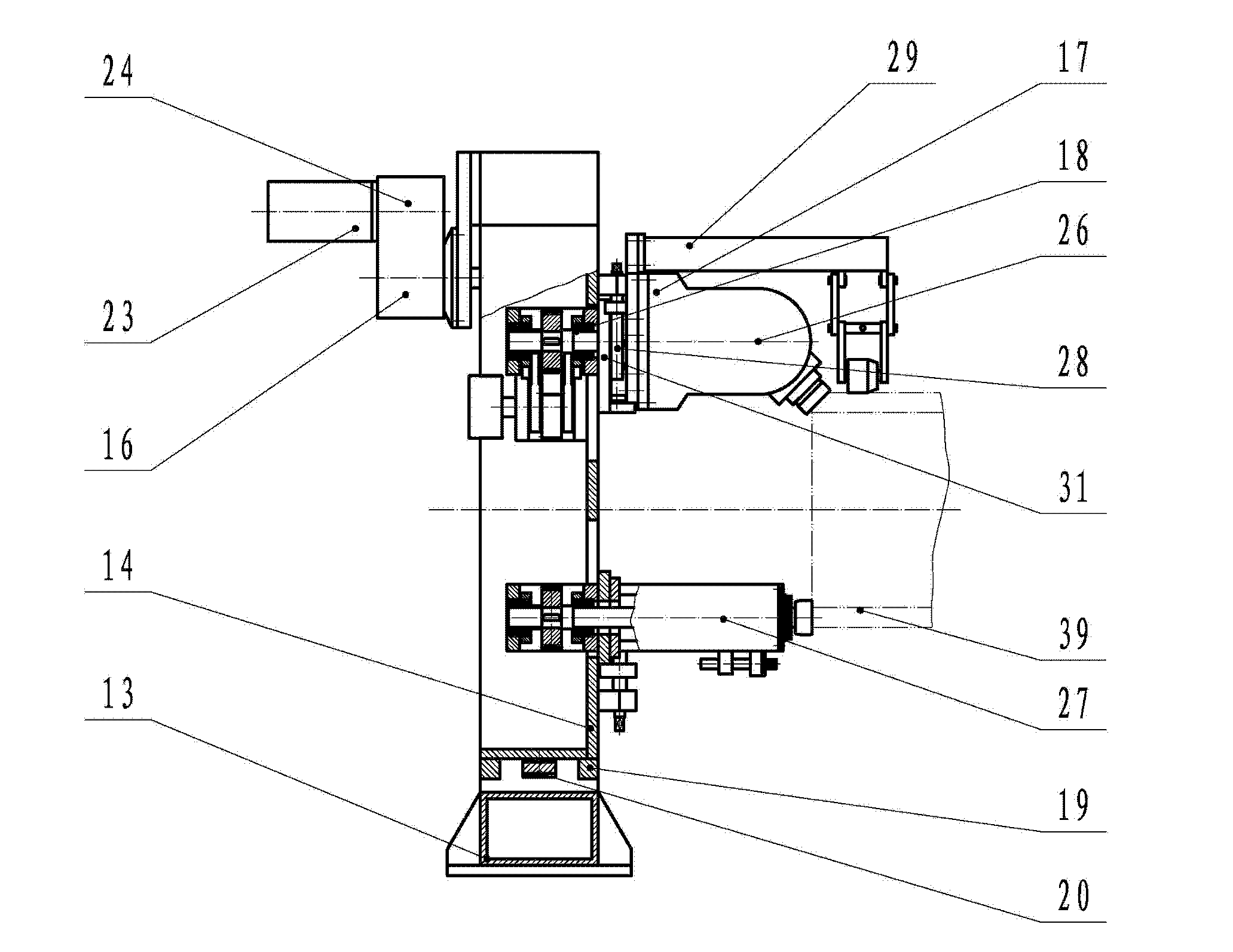

[0024] A processing equipment for the end face of large diameter, large wall thickness and high steel grade steel pipe, such as figure 1 , figure 2 As shown, it includes a fixed base 1, a movable base 2, a central gear transmission support device 3, a dedicated power head 4 and a feed mechanism 5.

[0025] The fixed base 1 is a steel plate welded plate structure, the lower surface is installed on the foundation, and the upper surface is installed with two linear guides 6;

[0026] The movable base 2 is a steel plate welded plate structure, and a slider 7 is installed on the lower surface and forms a sliding fit with the linear guide 6 of the fixed base;

[0027] The center wheel transmission support device 3 includes a transmission mechanism, a center gear 8 and a support base 9. The transmission mechanism and the center gear 8 are respectively cantilever mounted on both ends of the support base 9. The transmission mechanism is composed of a motor 10 and a reducer 11, and the reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com